Your First Line of Defense Against Costly Downtime

Your industrial roof is more than just a cover; it’s the primary shield protecting your entire business operation. It safeguards your valuable machinery, your inventory, your employees, and your ability to meet production deadlines. When you need industrial roofing repairs near me, you’re not just fixing a leak; you’re reinforcing your business’s resilience and preventing catastrophic financial losses. Finding qualified local contractors who understand the complex and unique challenges of commercial and industrial roofing systems is not just important—it’s mission-critical.

Here’s what every facility manager and business owner should look for in a roofing partner:

- Verifiable Licensing and Comprehensive Insurance: This is the absolute baseline. Contractors must hold the correct state and local licenses and carry both general liability and worker’s compensation insurance to protect your business from any liability.

- Deep Local Expertise: A contractor familiar with Alabama’s specific building codes, permitting processes, and volatile weather patterns—from intense summer heat and UV radiation to the threat of hurricanes and tornados—is invaluable.

- 24/7 Emergency Response Capabilities: Roof failures don’t happen on a 9-to-5 schedule. A dedicated emergency team can be the difference between a manageable repair and a full-blown operational shutdown.

- Specialized Knowledge of Industrial Roofing Materials: Expertise in TPO, EPDM, PVC, metal, and built-up roofing (BUR) is non-negotiable. Each system requires different tools, techniques, and materials for a lasting repair.

- A Proven Track Record with Local References: A reputable contractor will be proud to share references from other local industrial or commercial businesses. Speaking to them provides unfiltered insight into their professionalism, communication, and quality of work.

- Commitment to Safety: A contractor should have a documented safety program and adhere to all OSHA standards to ensure a safe worksite.

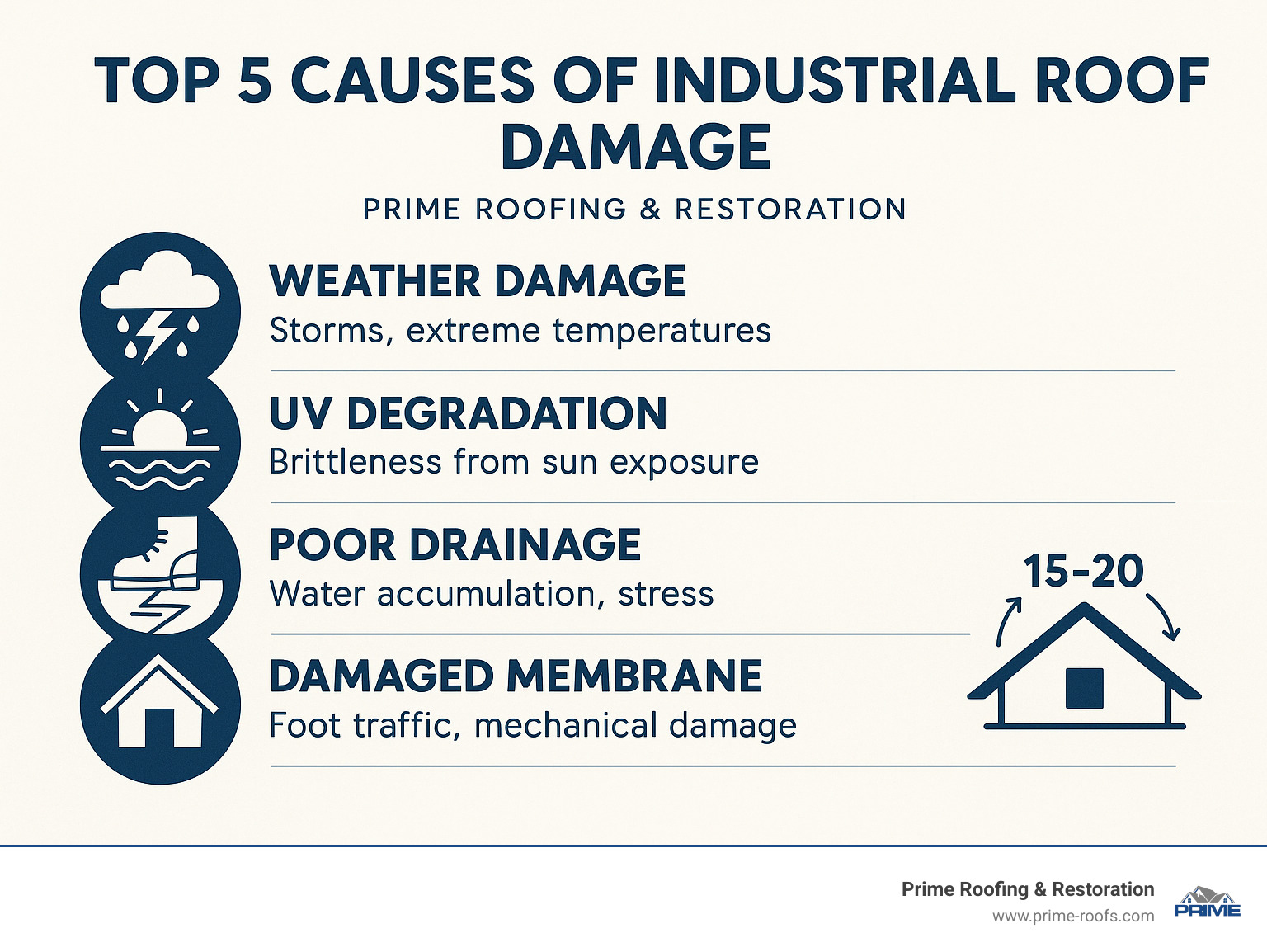

A seemingly small leak in an expansive industrial roof can quickly escalate, disrupting complex operations, ruining thousands of dollars in inventory, and creating hazardous working conditions. Industrial roofs typically have a lifespan of 15 to 20 years, but this lifespan is heavily dependent on proactive maintenance and swift, professional repairs. Neglect can shorten it dramatically.

Protecting your commercial property is a critical investment that starts from the top down. This guide offers a comprehensive, step-by-step approach to finding expert commercial roofing services to keep your facility safe, dry, and fully operational.

At Prime Roofing & Restoration, we have over five years of dedicated experience helping Alabama businesses with reliable industrial roofing repairs near me. Our team specializes in the complexities of flat and low-slope roof systems, TPO and EPDM repairs, and rapid-response emergency services across the Gulf Coast. We understand that industrial roofs face severe and constant wear from their large, uninterrupted surface areas, constant exposure to harsh elements, and the stress of heavy rooftop equipment. We are your local partners in asset protection.

Red Flags: 7 Telltale Signs Your Industrial Roof Needs Immediate Attention

Your industrial roof is a silent guardian, but it rarely fails without warning. It sends out distress signals that, if caught early, can save you from extensive damage and operational chaos. Knowing what to look for and acting with urgency is the key to effective roof asset management. When you spot these red flags, it’s time to search for industrial roofing repairs near me.

1. Leaks and Water Stains: This is the most obvious cry for help. Discoloration on ceiling tiles, dark streaks on walls, or active drips are undeniable proof that water has breached your primary defense. Don’t just put a bucket under it; this indicates a failure point that is likely causing unseen damage to insulation and decking.

2. Pooling or Ponding Water: Any water standing on a flat roof for more than 48 hours after rainfall is a major red flag. This condition, known as ponding, adds immense weight, stressing the roof structure. The constant moisture accelerates the deterioration of roofing materials, leading to premature failure and leaks.

3. Visible Membrane Damage: Your roof’s membrane is its skin. Look for cracks, blisters (which look like bubbles under the surface), punctures from dropped tools or debris, and alligatoring (interconnecting cracks that resemble alligator skin). These are direct invitations for water to penetrate your building’s protective barrier.

4. Rust or Corrosion on Metal Components: This isn’t just a cosmetic issue; it’s a sign of structural decay. Rusted fasteners, flashing around vents and HVAC units, or corroding metal panels are weakened points that can no longer provide a watertight seal. Corroded fasteners can fail, leading to panel uplift in high winds.

5. Sagging or Structural Weakness: This is a frantic, five-alarm red flag. Any noticeable bowing, dipping, or sagging in your roof’s profile indicates serious, potentially catastrophic, underlying structural problems. This could be caused by saturated insulation and a failing roof deck, and it requires immediate professional assessment to prevent a collapse.

6. Unexplained Spikes in Energy Bills: A sudden increase in your heating or cooling costs can be a subtle sign of roof failure. When the roofing membrane is damaged, it can lead to wet, compressed insulation that loses its R-value. This breach in the building envelope forces your HVAC system to work much harder to maintain a stable indoor temperature, increasing operational costs.

7. Clogged Drains, Gutters, and Scuppers: Your roof’s drainage system is critical. When drains and gutters are clogged with leaves, dirt, and other debris, water has nowhere to go. It backs up, creating ponding water and forcing its way into any available seam or crack, often leading to leaks far from the actual clog.

If you’re observing any of these warning signs, don’t wait for the problem to escalate. A professional roof inspection can provide a thorough assessment from experienced professionals who understand the nuances of industrial roofing repairs near me.

Obvious Damage vs. Hidden Dangers

Not all roof problems are immediately visible from the facility floor. Some work insidiously behind the scenes, causing extensive and expensive damage long before they become obvious.

Visible damage is straightforward. It includes large cracks, tears in the membrane, and broken seals around penetrations that you can spot during a rooftop walkthrough. Heavy foot traffic from HVAC technicians or damage from dropped tools can compromise your membrane, creating obvious entry points for water.

The hidden dangers are the silent destroyers. Musty odors inside your facility often signal mold and mildew growth from water infiltration you haven’t found yet. Mold growth thrives in the damp, dark spaces created by undetected leaks, posing serious health hazards for employees and potentially contaminating sensitive products or inventory.

Perhaps the most concerning hidden danger is compromised support structures. When a minor leak goes undetected, it slowly saturates the roof insulation. This wet insulation acts like a giant sponge, adding thousands of pounds of dead weight to the roof deck and weakening the steel or wood structural components. A small, ignored puncture can eventually compromise your building’s entire structural integrity.

It’s crucial to have a professional who can identify and address both visible and hidden issues. Regular professional inspections are designed to catch these hidden dangers before they become costly disasters.

When to Call for Emergency Service

Some roofing situations are true emergencies that cannot wait. When your building’s integrity, your employees’ safety, or your core business operations are under immediate threat, you need professional help right away.

- Active Leaks Over Critical Equipment: Water dripping onto production machinery, servers, or electrical panels is an emergency that can cause irreparable damage and create fire hazards.

- Significant Storm Damage: Alabama’s weather can be severe. After a major storm with high winds, hail, or torrential rain, an immediate inspection is needed to assess for punctures, lifted panels, and other damage that will worsen quickly.

- Punctures from Falling Debris: A fallen tree limb or debris from another structure can create a large, immediate vulnerability in your roof system, allowing for rapid and widespread water intrusion.

- Compromised Structural Integrity: This is the most serious emergency. Any visible sagging, creaking sounds, or sudden changes to your roof’s profile warrant an immediate evacuation and a call to a professional to prevent a potential collapse.

We offer 24/7 emergency roof service for these urgent situations because we understand that roofing emergencies don’t follow a convenient schedule. When you need industrial roofing repairs near me urgently, a trusted local contractor who can respond quickly can mean the difference between a manageable repair and a catastrophic loss.

Not All Roofs Are Created Equal: Matching Repair Strategies to Your Roofing System

Industrial roofing is not a one-size-fits-all discipline. The material protecting your facility dictates the entire repair strategy, from the tools and techniques used to the expertise required. Different materials require highly specialized repair techniques, and understanding your specific roof type is the first and most critical step toward an effective, durable, and cost-effective repair.

When you’re searching for industrial roofing repairs near me, being able to tell a potential contractor, “I have a TPO roof with a suspected seam failure,” immediately helps you find a company with the right expertise. Each material has unique properties, vulnerabilities, and repair protocols.

Common Industrial Roof Types and Their Repair Needs

Metal Roofing: A popular choice for its durability and long lifespan (often 50+ years). However, it’s vulnerable to rust and corrosion, especially at cut edges and around fasteners. Seam separation due to thermal expansion and contraction is another common issue, as is fastener back-out, which creates a small but direct path for water.

EPDM (Ethylene Propylene Diene Monomer): Often called a “rubber roof,” this flexible single-ply membrane is a reliable choice for flat roofs, lasting 20-30 years. Its biggest weaknesses are punctures from sharp debris or foot traffic and seam adhesion failure, where the adhesive holding the seams together can degrade over time due to UV exposure and weathering.

TPO (Thermoplastic Olefin): A modern, energy-efficient single-ply membrane known for its white, reflective surface. It typically lasts 15-20 years. Its seams are heat-welded to form a monolithic layer, but improper installation can lead to weld failures. It is also susceptible to punctures from mechanical damage.

PVC (Polyvinyl Chloride): Another durable single-ply membrane, PVC is highly resistant to chemicals, grease, and fire, making it an excellent choice for manufacturing plants and restaurants. Like TPO, its seams are heat-welded, and it can be punctured, but its primary advantage is its chemical resistance.

Built-Up Roofing (BUR): The traditional “tar and gravel” roof, BUR uses multiple layers of asphalt-saturated felt and bitumen to create a thick, robust, and redundant barrier. Though very durable, it can suffer from blistering, cracking, and water saturation of the underlying layers, which requires messy and labor-intensive repairs to remove and rebuild the damaged sections.

| Roof Type | Typical Lifespan | Common Issues | Repair Methods |

|---|---|---|---|

| Metal | 50+ years | Rust, seam separation, fastener failure | Sealing, coating, panel replacement, fastener tightening |

| TPO | 15-20 years | Weld failures, punctures, membrane shrinkage | Heat welding, membrane patches, detail work |

| EPDM | 20-30 years | Punctures, seam adhesion failure, shrinkage | Adhesive patches, seam tape, liquid-applied sealants |

| PVC | 20-30+ years | Punctures, weld failures | Heat welding, membrane patches |

| BUR | 20-30 years | Blistering, cracking, ponding water | Patching with asphalt/fabric, coatings, section removal |

Explore our comprehensive commercial roofing services to learn more about these different systems and our specialized repair capabilities.

How Different Materials Affect Industrial Roofing Repairs Near Me

The material covering your building dictates the entire repair approach. Using the wrong product or technique can do more harm than good, turning a simple fix into a costly failure. What works for one material could chemically damage another.

Metal roof repair is a specialized skill. It involves mechanically abrading rust, treating the area with a rust-inhibiting primer, and then sealing with elastomeric coatings or specialized tapes designed to flex with the metal’s movement. Using an incompatible sealant can cause corrosion or fail to adhere properly.

EPDM repair requires meticulous surface preparation. The area must be cleaned with a specific agent, then primed to ensure a strong bond for the adhesive patch or seam tape. Using the wrong cleaner or skipping the primer will result in patch failure. Our EPDM Roof Repair Guide offers detailed insights into these specialized processes.

TPO and PVC repair both rely on heat welding. A skilled technician uses a hot-air welder at a precise temperature and speed to fuse a new piece of membrane to the existing roof, creating a permanent, monolithic bond. This is a skill that requires training and experience; improper welding can result in a weak seam that fails quickly.

BUR repair is often the most labor-intensive. It involves cutting out the blistered or saturated section down to the deck, removing all wet materials, and then rebuilding the layers with new felt and hot asphalt or cold-process adhesives, ensuring each layer is properly sealed.

The bottom line is clear: choosing a contractor with documented, hands-on experience with your specific roofing material isn’t just preferred—it’s absolutely essential for a repair that will protect your investment for years to come. Always ask a potential contractor to provide case studies or references for projects involving your roof type.

How to Find Reliable Industrial Roofing Repairs Near Me

Finding a qualified, trustworthy, and local contractor is the most critical step in addressing your industrial roofing needs. Your choice of contractor will determine the quality of the repair, the safety of the project, and the long-term performance of your roof. Look for a partner who demonstrates deep experience, proper credentials, and an unwavering commitment to safety. A top-tier contractor means the difference between a temporary patch and a durable, long-term solution.

The Ultimate Contractor Vetting Checklist

Hiring an industrial roofing contractor is a significant business decision. When searching for industrial roofing repairs near me, it’s vital to conduct thorough due diligence rather than simply choosing the first or cheapest option. Use this checklist to vet potential partners:

-

Are you properly licensed and insured? This is the first and most important question. Ask for a copy of their state license and a Certificate of Insurance (COI). Verify that they carry both General Liability insurance (to cover property damage) and Worker’s Compensation insurance (to cover injuries to their crew). Without this, you could be held liable.

-

Can you provide local references for similar projects? A reputable contractor will gladly provide a list of recent clients. Ask for references for businesses with a roof of similar size and material to yours. Call them and ask about the contractor’s communication, timeliness, site cleanliness, and the performance of the repair.

-

What specific warranties do you offer? You need to understand two types of warranties. The manufacturer’s warranty covers the materials themselves against defects. The contractor’s workmanship warranty covers the labor and installation. A contractor who offers a strong, long-term workmanship warranty is confident in their work.

-

How do you ensure site safety? Industrial roofing is inherently dangerous. A professional contractor will have a comprehensive, written safety plan and be able to discuss it with you. Ask about their safety record, their training protocols, and their Experience Modification Rate (EMR), an insurance industry metric for safety.

-

Who will be my point of contact and what is the project plan? You should have a dedicated project manager. Ask for a detailed, itemized proposal that outlines the scope of work, materials to be used, project timeline, and payment schedule. Vague proposals are a red flag.

Finally, verify their experience with your specific roof type. A contractor who primarily installs residential shingles is not the right choice for your complex TPO or EPDM industrial system. Read our guide on choosing a roofer for more tips on making the right selection.

Why Local Expertise Matters for Alabaster, AL Businesses

Choosing a local roofing contractor in the Alabaster, AL, area means hiring a team that intimately understands the unique challenges your building faces every day.

Knowledge of Local Building Codes: Local contractors are experts in Alabaster’s specific municipal codes and regulations. This ensures your project is fully compliant from the start, saving you from costly fines and rework.

Understanding Alabama’s Harsh Weather Patterns: Local experts know how to build and repair roofs that can withstand the brutal summer sun, high humidity, and the constant threat of severe thunderstorms and hurricanes. They will recommend materials and techniques proven to perform in our climate, not a generic solution.

Faster Response Times for Emergencies: When a storm hits or a major leak appears, proximity matters. A local team can be on-site within hours, not days, to mitigate damage and prevent a minor issue from becoming a major business shutdown.

Supporting the Local Economy: Hiring a local business keeps your investment in the community, supporting local jobs and families.

Accessibility and Accountability: When your contractor is just down the road, they are more accessible for follow-up questions and accountable for the work they perform. You’re not just a number on a spreadsheet; you’re a neighbor.

Find your trusted local roofers in Alabaster, AL who understand your specific needs and challenges.

Safety First: Verifying Credentials and Safety Records

Industrial roofing consistently ranks as one of the most dangerous professions. A contractor’s commitment to safety is not just about compliance; it’s about protecting lives and your property. A safe job site is an efficient and professional job site.

In the US, always verify OSHA compliance. A reputable contractor should be able to provide their OSHA 300 logs and discuss their site-specific safety plans. Review OSHA’s guidelines for roofing safety to understand what proper fall protection and site management look like.

A responsible contractor invests heavily in safety. This includes:

- A clear, documented safety plan for every project.

- Providing all necessary Personal Protective Equipment (PPE), including fall arrest systems, hard hats, and high-visibility clothing.

- Regular safety training (toolbox talks) for their entire crew.

- Proper procedures for ladder, scaffolding, and aerial lift safety.

Better Business Bureau (BBB) ratings can also offer valuable insight into a company’s professionalism, ethics, and commitment to customer satisfaction. Look for contractors with high ratings and a history of resolving any complaints amicably.

Your Local Industrial Roofing Experts in Alabaster

When you need reliable industrial roofing repairs near me in the Alabaster, AL area, you don’t have to look far. We are a part of this community, and we’ve been serving local businesses for years, building a reputation for quality and reliability one roof at a time.

Prime Roofing & Restoration

Address: 5 Brown Cir, Alabaster, AL 35007

Phone: (205) 661-8190

We pride ourselves on building lasting relationships with our clients, using only high-quality materials from trusted manufacturers, and providing 24/7 emergency service with licensed experts to protect your business. When you call us, you’re getting a dedicated partner who understands that your roof is essential to keeping your business running.

The Payoff: Long-Term Benefits of Prompt and Professional Repairs

It’s time to shift your perspective. Stop thinking of industrial roofing repairs near me as a reactive expense and start seeing them as a strategic investment in your business’s continuity and profitability. Acting quickly and choosing professional, qualified contractors protects your entire operation, enhances your property’s value, and delivers a significant return on investment for years to come. A well-maintained roof is a cornerstone of operational excellence and financial stability.

Extend Your Roof’s Lifespan and Avoid Premature Replacement

Industrial roofing systems are engineered to last for decades, but they only reach their full potential with proper care. Proactive repairs and preventative maintenance can be the difference between a roof lasting its full 25-year intended lifespan versus needing a costly premature replacement after only 15 years. Think of it like the routine maintenance on your critical production machinery; you perform it to prevent catastrophic failure and maximize its service life. Your roof is no different.

When you address small issues—like loose flashing, a small puncture, or a clogged drain—early, you prevent them from evolving into widespread, systemic damage that requires expensive, disruptive intervention. A $750 repair to seal an open seam today can prevent a $75,000 project to replace saturated insulation and a rusted roof deck five years from now.

Stop minor issues from escalating. Water is a relentless force that will find and exploit every weakness. A scheduled commercial roof maintenance plan is your best defense against these surprise costs and is the single most effective way to avoid a premature and budget-breaking roof replacement.

The True Cost of Neglecting Industrial Roofing Repairs Near Me

Ignoring roof problems is a gamble that never pays off; it always costs more to fix later. The initial savings from deferring a repair are dwarfed by the exponential costs of the resulting damage. Here’s a breakdown of the real risks you take when you neglect your roof:

-

Catastrophic Structural Damage: Water intrusion is insidious. It slowly saturates insulation, rots wood decking, rusts steel supports, and weakens the overall structural integrity of your building. What starts as a minor leak can eventually lead to a partial roof collapse, endangering lives and property.

-

Damaged Inventory and Equipment: A single major leak can destroy expensive manufacturing equipment, ruin pallets of finished goods, or contaminate raw materials. The cost of this damage can easily wipe out months of profit in a single afternoon.

-

Expensive Mold Remediation: Where there is moisture, there will be mold. Mold creates serious health hazards for your employees, leading to respiratory problems and other illnesses. Professional mold remediation is disruptive, expensive, and often not covered by standard insurance policies.

-

Crippling Business Interruption: A catastrophic roof failure means lost revenue for every single hour your facility is closed. You can’t meet customer orders, your supply chain is disrupted, and your hard-won reputation suffers. The costs of downtime often exceed the cost of the repair itself.

-

Skyrocketing Future Repair Bills: Postponing maintenance guarantees that future repair bills will be significantly higher. Water damage spreads, turning a localized problem into a system-wide failure. A small patch job becomes a large-scale restoration or a full replacement.

-

Serious Safety Hazards and Liability: Neglected roofs create a minefield of risks. These include slips and falls from wet floors, electrical shorts and fire hazards from water contacting wiring, and injuries from falling debris or structural instability. The liability and legal costs from a single accident can be devastating.

-

Increased Insurance Premiums: Insurance companies may view a poorly maintained roof as a high risk, leading to increased premiums or even non-renewal of your policy.

The math is simple and unforgiving: investing in timely, professional repairs saves an enormous amount of money, protects your assets, and ensures operational stability. Every day you wait, the problem gets bigger and more expensive.

Frequently Asked Questions about Industrial Roof Repairs

When you’re facing an issue with your facility’s roof, you undoubtedly have questions and concerns. We’ve been helping Alabama businesses with industrial roofing repairs near me for over five years, and in that time, we’ve found that our clients often have the same key questions. Here are clear, straightforward answers to the things we hear most often.

How much do industrial roof repairs cost?

The cost of industrial roofing repairs near me can vary significantly based on several key factors. There is no one-size-fits-all price, so it’s crucial to get a detailed, itemized estimate.

- Minor Repairs: Simple fixes like patching a small puncture on a TPO roof, sealing a few loose fasteners on a metal roof, or clearing a clogged drain might cost anywhere from $500 to $2,500.

- Moderate Repairs: More involved work, such as repairing a significant length of failed seam, replacing a section of damaged membrane, or installing a new drain, could range from $2,500 to $10,000.

- Major Repairs: Extensive work involving the replacement of large sections of membrane and underlying wet insulation, or significant structural work, could cost $10,000 to $50,000 or more.

The primary cost drivers are the size of the damaged area, the type of roofing material (specialized materials and techniques cost more), roof accessibility (will a crane be needed?), and the extent of underlying damage to the insulation or roof deck.

Always insist on a detailed estimate from a qualified contractor that breaks down the scope of work, material costs, and labor costs so you know exactly what you’re paying for.

Can my industrial roof be repaired, or does it need to be replaced?

This is one of the most critical questions, and the right answer requires a thorough professional inspection. However, here are the factors we consider:

- Age of the Roof: If your roof is approaching or has surpassed its typical 15-20 year lifespan and is experiencing multiple issues, a full replacement often makes more long-term financial sense than continuing to sink money into frequent repairs.

- The 25% Rule: This is a common industry guideline. If more than 25% of your total roof surface is damaged, deteriorated, or saturated, a commercial roof replacement is almost always the more cost-effective and reliable choice.

- Structural Integrity: This is non-negotiable. If a professional inspection reveals that water damage has compromised the underlying roof deck or structural supports, replacement is typically the only safe and viable option.

- Consider a Restoration: If the roof is structurally sound but the membrane is aging or has widespread surface-level issues, a roof restoration coating can be an excellent middle ground. A fluid-applied silicone or acrylic system can add 10-15 years of life to your existing roof at a fraction of the cost of a full replacement.

Ultimately, a qualified contractor can perform a core sample analysis and a thorough inspection to provide you with clear options, helping you make an informed decision that protects your budget and your business.

How long do industrial roof repairs take?

The timeline for a repair project depends entirely on the scope of work and other variables.

- Quick Fixes: Small, straightforward repairs like patching a leak or sealing a pipe flashing can often be completed in a single day, minimizing disruption to your operations.

- Larger Projects: More extensive repairs, such as replacing a large section of the roof or applying a restoration coating to a significant area, may take several days to a week to complete properly.

- Major Replacements: A full roof replacement is a major construction project and can take several weeks, depending on the size of the roof, weather conditions, and logistical complexity.

Your contractor should provide a clear, realistic timeline as part of their proposal. They should also work with you to develop a phasing plan that minimizes disruption to your business, scheduling noisy or disruptive work during off-hours or weekends whenever possible.

Conclusion: Secure Your Investment with an Expert Roofing Partner

Your industrial roof is one of your most valuable business assets. It is the silent, essential shield that protects your people, your equipment, and your entire operational capacity from the elements. Don’t let a damaged or deteriorating roof compromise your business’s safety, productivity, and profitability when a reliable, professional solution is within reach.

By learning to identify the critical warning signs early, understanding the specific needs of your roofing system, and partnering with a thoroughly vetted, reputable local contractor, you can prevent small issues from becoming costly, business-halting disasters. This proactive approach ensures you receive quality work that stands the test of time and the harsh Alabama weather.

A proactive approach to roof health is simply smart business. It is a strategic investment that protects your other, more visible assets, ensures your operations never skip a beat, extends the life of your building, and can even boost your facility’s energy efficiency and lower your operating costs.

When you’re searching for reliable industrial roofing repairs near me, local experience and a proven track record matter immensely. You need a partner who understands the unique challenges of our climate, the specific demands of industrial facilities, and the importance of minimizing downtime.

That’s where Prime Roofing & Restoration comes in. We have spent over five years building our reputation in Alabaster and the surrounding communities by helping businesses like yours stay safe, dry, and operational. Our team knows industrial roofing inside and out—from 24/7 emergency storm response to developing proactive maintenance plans that prevent problems before they ever start. We are not just a contractor; we are your partner in asset protection.

Ready to take the first step toward securing your facility’s future? Contact us today for a free, no-obligation inspection and let our experts provide you with a clear assessment of your roof’s health. Let us help you keep your business covered, because when it comes to your roof, you deserve a partner who cares as much about your success as you do.