EPDM Commercial Roofing: Your Guide to a 50-Year, Weatherproof Roof

EPDM commercial roofing is a high-performance synthetic rubber membrane system that has been a cornerstone of the commercial roofing industry for nearly 60 years. First introduced in the 1960s, this time-tested material has proven its mettle on millions of square feet of roofing across the globe. EPDM is an acronym for its core chemical components: ethylene, propylene, diene, and monomer. These ingredients are synthesized to create an exceptionally durable, flexible, and waterproof single-ply membrane, making it an ideal solution for the unique challenges of flat and low-slope commercial buildings. As a leading provider of comprehensive roofing solutions, we have consistently seen how a properly installed EPDM system delivers unmatched long-term value and peace of mind to property owners.

Flat and low-slope roofs, common on commercial and industrial structures, require a continuous, monolithic waterproof barrier. Unlike pitched roofs that use gravity to shed water, these roofs must be able to withstand pooling water, intense UV radiation, and significant temperature fluctuations. EPDM is engineered specifically for this demanding environment.

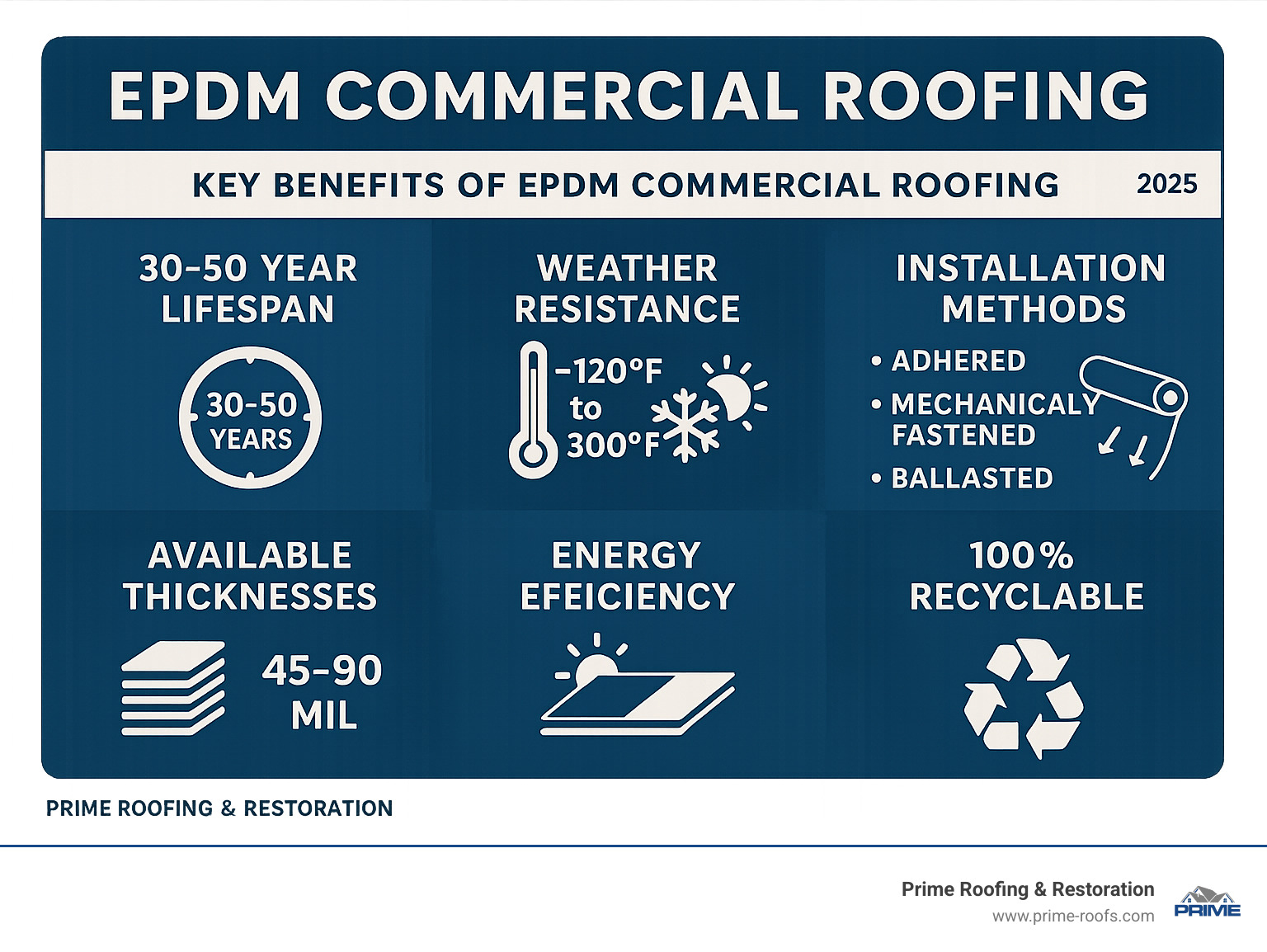

Key Benefits of EPDM Commercial Roofing:

- Exceptional Longevity: An EPDM roof is a long-term investment. With a proper installation and a consistent maintenance schedule, these systems can reliably last between 30 and 50 years, often outliving their initial warranty period by decades. This durability means fewer replacements and a lower life-cycle cost compared to many competing materials.

- Superior Weather Resistance: EPDM is formulated to withstand the harshest weather conditions. It remains flexible in extreme temperatures, from a frigid -120°F to a blistering 300°F, preventing cracks and splits. Its composition, often featuring carbon black, provides outstanding resistance to UV radiation and ozone, which degrade other materials over time.

- Unmatched Cost-Effectiveness: When analyzing both upfront installation costs and long-term expenses (maintenance, repairs, and replacement), EPDM often emerges as the most affordable and value-driven option for flat roofs. Its efficient installation process and minimal maintenance needs contribute to a lower total cost of ownership.

- Year-Round Installation Flexibility: Because EPDM does not become brittle in the cold, and its seam tape technology is not as temperature-sensitive as some welded systems, it can be installed in a wider range of weather conditions. This flexibility allows for more scheduling freedom, minimizing disruptions to your business operations.

- Climate-Adapted Energy Efficiency: EPDM is available in traditional black membranes, which help reduce heating costs in cooler climates by absorbing solar energy, and reflective white membranes, which lower cooling costs in warmer climates by reflecting sunlight. This choice allows you to tailor your roof to your specific climate for optimal energy performance.

- Proven Eco-Friendly Solution: At the end of its extensive service life, EPDM is 100% recyclable, diverting tons of waste from landfills. Its manufacturing process has a low global warming potential, making it a responsible choice for sustainable building projects.

If you’re exploring reliable commercial roofing services for your Alabama property, EPDM stands out as a proven solution that delivers decades of protection and financial value. EPDM roofs are available in three standard thicknesses (45, 60, and 90 mil) and can be installed using three distinct methods: fully adhered, mechanically fastened, or ballasted. The use of wide sheets minimizes the number of seams, and the advanced seam tape technology creates a powerful, watertight barrier that resists punctures, leaks, and building movement.

I’m Bill Spencer, owner of Prime Roofing & Restoration, and I’ve dedicated my career to helping Alabama commercial property owners select and install the perfect EPDM commercial roofing system for their buildings. With over five years of hands-on experience specializing in flat roof systems and storm-resistant designs, I have an intimate understanding of how EPDM performs in our demanding Gulf Coast climate, from intense summer sun to hurricane-force winds.

60 Years of Proof: Why EPDM Dominates Commercial Roofing

When you’re evaluating roofing options for your commercial building, EPDM commercial roofing consistently rises to the top, and for good reason. This synthetic rubber membrane has been successfully protecting businesses for nearly six decades, a track record of reliability that few other single-ply systems can claim. Its dominance isn’t an accident; it’s the result of a superior combination of durability, flexibility, and cost-effectiveness that savvy building owners and facility managers have come to depend on.

What truly sets EPDM apart? Unlike some roofing materials that become rigid and crack in cold weather or grow brittle under years of sun exposure, EPDM’s thermoset polymer structure ensures it remains flexible and resilient year-round. It’s also surprisingly lightweight, which means it can often be installed without requiring costly structural reinforcements to your building. The ultimate advantage, however, is its remarkable longevity. With a proper maintenance plan, your EPDM commercial roofing system can safeguard your investment for 30 to 50 years. That’s decades of dependable, leak-free performance, translating to significant long-term savings and operational continuity.

But EPDM isn’t just about lasting a long time—it’s about performing at a high level throughout its entire service life. This material has earned its stellar reputation by consistently delivering superior weather resistance, tangible energy efficiency, and environmental benefits that align with the goals of modern commercial property owners.

Best-in-Class Durability and Weather Resistance

When Mother Nature unleashes her worst, from hailstorms to hurricane-force winds, EPDM commercial roofing stands as a formidable line of defense. This claim is not mere marketing hyperbole; it’s substantiated by six decades of real-world performance data and rigorous laboratory testing against industry standards.

Hail impact resistance is a critical performance metric, and it’s where EPDM truly excels. The membrane’s rubber composition allows it to absorb the force of hail impacts without fracturing. Thicker membranes (60 and 90 mil), especially when installed over a high-density cover board or in a ballasted system, create an exceptionally tough barrier that resists punctures from even large hailstones, keeping your roof watertight after severe storms. Many EPDM systems are tested to and pass the demanding FM 4470 Class 1, 2, or 3 hail-resistance ratings.

Wind uplift performance is another area where EPDM demonstrates its superiority, a crucial factor in Alabama’s storm-prone climate. Fully adhered systems, where the membrane is bonded directly to the substrate, create a powerful, monolithic bond that can withstand significant negative pressure and wind forces, meeting or exceeding strict standards like the ANSI/SPRI WD-1 test protocols. This robust attachment prevents the membrane from peeling or billowing during high-wind events, protecting the entire roofing assembly.

The UV radiation protection engineered into EPDM is remarkable. Most black EPDM membranes incorporate a high concentration of carbon black, one of the most effective UV-blocking agents known. This ingredient absorbs harmful ultraviolet radiation and dissipates it as heat, preventing the polymer chains from breaking down. This is why EPDM maintains its physical properties and integrity decade after decade, while other materials can weaken and degrade under constant sun exposure.

Extreme temperature tolerance showcases EPDM’s robust chemical nature. As a thermoset material, its chemical cross-links are ‘set’ during manufacturing, making it incredibly stable. It performs reliably in a vast temperature range, from -120°F to 300°F. Whether it’s a frigid winter morning that makes other materials brittle or a scorching summer afternoon that can cause thermal shock, your EPDM roof continues to perform without compromise.

Ozone resistance is another key benefit. EPDM consistently earns an ‘A’ rating for ozone resistance in temperatures up to 100°F. This protects the membrane against degradation from atmospheric ozone, an often-overlooked factor that can weaken and shorten the lifespan of less-resistant materials over time.

Perhaps most impressive is EPDM’s phenomenal ability to accommodate building movement. The membrane can stretch to over 300% of its original size and return to its initial form without tearing or damage. This incredible elongation capacity means it easily moves with your building as it naturally expands and contracts with thermal changes. This flexibility prevents the formation of cracks, splits, and seam stress that cause expensive leaks in more rigid roofing systems.

Superior Energy Efficiency and Environmental Impact

EPDM commercial roofing is not just a tough shield; it’s also an intelligent choice for energy management and environmental stewardship. The decision between a black or white EPDM membrane can have a direct and significant impact on your building’s energy consumption and utility bills.

Black EPDM utilizes its carbon black content to absorb UV rays and convert them into heat. In cooler, northern climates, this passive solar gain can substantially reduce heating costs during the winter months. It effectively turns your roof into a large solar collector, offsetting the energy needed to heat the building and lowering your carbon footprint.

White EPDM, on the other hand, is a highly reflective ‘cool roof’ material. It incorporates titanium dioxide to reflect a high percentage of solar radiation away from the building. According to studies by organizations like the Cool Roof Rating Council (CRRC), a reflective roof can lower surface temperatures by up to 50°F, leading to a 10-15% reduction in peak cooling energy demand in warm climates like Alabama’s. While white EPDM may allow slightly more heat loss in winter compared to black, the year-round cooling savings in southern states typically provide a compelling return on investment.

The recyclability of EPDM positions it as a leader in sustainable construction. At the end of its exceptionally long service life, the entire membrane, including seam tape, can be reclaimed and recycled into new products like walkway pads, rubber flooring, and other construction materials. This closed-loop potential dramatically reduces landfill waste.

Green roof integration is another powerful environmental benefit. EPDM’s inherent waterproof nature and root-puncture resistance make it an ideal waterproofing layer for vegetative or ‘green’ roof systems. These installations offer numerous advantages, including improved stormwater management, reduced urban heat island effect, enhanced building insulation, and improved local air quality.

According to studies conducted by the U.S. Environmental Protection Agency (EPA), EPDM demonstrates the lowest global warming potential when compared to other common commercial roofing materials. It also has a minimal impact on smog formation and acid rain. This strong environmental profile has led organizations like Greenpeace to recognize EPDM as a preferred sustainable roofing choice for environmentally conscious projects.

These combined energy and environmental benefits make an investment in EPDM commercial roofing not just a smart financial decision for your business, but a responsible one for your community and the planet.

Inside an EPDM Roof: The Layers That Guarantee Performance

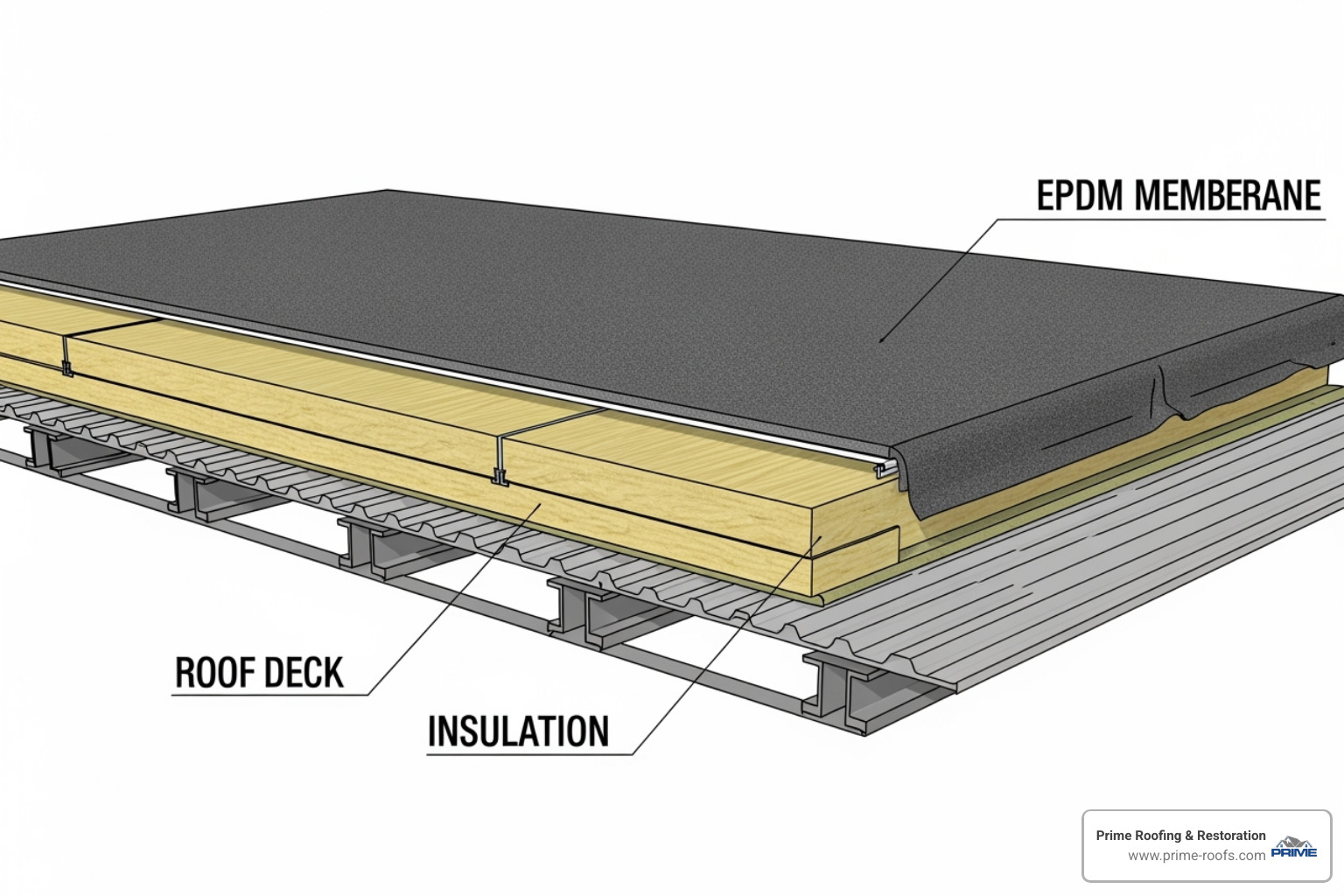

To truly appreciate the resilience of EPDM commercial roofing, it’s best to think of it as a meticulously engineered system, not just a simple rubber sheet. While EPDM is classified as a single-ply membrane—meaning it relies on one layer of waterproofing material—the complete roof assembly is a multi-layered sandwich. Each component is specifically designed to work in concert with the others to protect your building from the elements.

A typical cross-section reveals the structural roof deck at the bottom (which can be steel, concrete, or wood), often followed by a vapor barrier, one or more layers of rigid insulation, a protective cover board, the EPDM membrane itself, and finally, the various flashing and accessory materials that seal the system at edges and penetrations. Every single component plays a critical role, and when they are installed correctly by certified professionals, they create a roofing system capable of protecting your commercial property for up to half a century.

At Prime Roofing & Restoration, we’ve installed countless EPDM systems across Alabama. I can personally attest that when property owners understand how these layers function together, they are better equipped to make informed decisions that protect their long-term roofing investment.

EPDM Membrane Options: Thickness and Reinforcement

Not all EPDM membranes are identical. The specifications you choose for thickness and reinforcement can make a significant difference in your roof’s durability, puncture resistance, and ultimate longevity.

The most widely specified thickness is 60 mil (0.060 inches). This option provides an excellent balance of robust durability and cost-effectiveness, making it the standard for most commercial applications. It is thick enough to withstand punctures from routine roof traffic, falling debris, and dropped tools, yet remains an economical choice for budget-conscious property owners.

For lighter-duty applications, such as a roof with no mechanical equipment and very limited access, 45 mil (0.045 inches) EPDM offers fundamental waterproofing protection at the lowest initial cost. However, we typically recommend this thickness only for buildings in mild climates where the risk of physical damage is minimal.

When your building demands maximum protection against harsh weather, heavy foot traffic, or the risk of flying debris, 90 mil (0.090 inches) EPDM is the premier choice. This is the thickest standard option and provides superior resistance against tears, punctures, and hail. When a 90 mil membrane is combined with a high-density cover board or used in a ballasted system, its resistance to physical damage can be exponentially greater than thinner systems. Some manufacturers, like Carlisle SynTec, also offer a 75 mil option, providing a durable middle ground between the 60 and 90 mil membranes.

Beyond thickness, you can choose between non-reinforced and reinforced membranes. Non-reinforced EPDM is a uniform, homogenous sheet known for its exceptional flexibility and elongation. Reinforced membranes, however, incorporate an internal polyester fabric scrim (typically a high-denier mat) for enhanced strength, dimensional stability, and superior resistance to punctures and tears. This reinforcement is particularly critical for mechanically fastened systems where the membrane must withstand stresses around the fasteners.

One of EPDM’s greatest installation advantages is its availability in wide sheets, typically ranging from 7.5 feet to 50 feet wide and up to 200 feet long. These large dimensions are a crucial benefit because they drastically minimize the number of seams required on a roof. Since seams are historically the most vulnerable points in any roofing system, fewer seams directly translate to fewer potential leak points and a more reliable, monolithic roof.

Essential Accessories and Components

The true performance of an EPDM commercial roofing system is unlocked by its supporting cast of accessories and components. These are not optional add-ons; they are integral players that ensure the system functions as a cohesive, watertight unit for decades.

Insulation boards are the foundation of your roof’s thermal performance. Polyiso (polyisocyanurate) is the most popular choice due to its high R-value per inch, helping to lower energy costs and meet modern building codes. Extruded Polystyrene (XPS) is another option, valued for its moisture resistance. These boards can be flat or tapered to create positive drainage on a flat roof.

Cover boards are installed over the insulation to provide a smooth, stable, and protective substrate for the EPDM membrane. Materials like high-density polyiso, gypsum-fiber roof boards (e.g., USG Securock® or DensDeck Prime®), or asphaltic boards add a critical layer of protection against punctures, hail, and fire.

Bonding adhesives are the glue that holds the system together in a fully adhered application. These specialized adhesives can be solvent-based for aggressive bonding, water-based for low-VOC applications, or even two-part foamable adhesives that secure both the insulation and membrane in a single step. The choice depends on substrate, climate, and project requirements.

The real heroes of modern EPDM systems are the seam tapes. Products like GenFlex’s Peel & Stick Seam Tape are advanced, butyl-based tapes that create incredibly strong, durable, and watertight seams between membrane sheets. They are far superior to the older, less reliable liquid adhesives used decades ago and are designed for easy application and decades of performance.

Primers are a small but critical step. Products like Carlisle’s HP-250 or GenPrime are used to clean and prepare the EPDM membrane surface before applying seam tapes and flashing. This ensures a powerful molecular bond, which is essential for long-term seam integrity.

Around the roof’s perimeter and at terminations, termination bars (metal strips) are used to mechanically fasten and seal the membrane. Waterstop mastic, a thick, butyl-based sealant, is applied behind the termination bar to create a compression seal, acting as a final barrier against water infiltration.

For an added layer of security, lap sealant is applied along all seam edges and over fastener heads. This liquid-applied EPDM sealant provides a secondary seal, offering peace of mind against moisture intrusion during Alabama’s heavy, wind-driven rain events.

Flashing components are used to waterproof complex details. Pre-fabricated pipe boots, inside/outside corners, and pourable sealer pockets are made from EPDM or compatible materials to expertly seal around pipes, vents, HVAC curbs, and other irregular penetrations that every roof has.

Finally, fasteners and plates are the backbone of mechanically attached systems. These specially coated screws and plates are engineered to secure insulation boards and EPDM membranes to the roof deck, providing the calculated resistance needed to combat wind uplift forces.

All these components are designed to work together as a system. You can find more info about system components from leading manufacturers, but success depends on an experienced contractor who understands how each piece contributes to the overall protection of your commercial property.

EPDM Installation & Costs: What to Expect for Your Commercial Roof

Proper installation is where the long-term value of your EPDM commercial roofing system is truly realized. While EPDM is known for being one of the more forgiving and efficient roofing materials to work with, achieving a 30- to 50-year service life depends entirely on the skill and precision of experienced, manufacturer-certified professionals who understand the nuances of each installation method.

The installation journey always begins with meticulous roof deck preparation. This critical first step involves ensuring the surface is completely clean, dry, smooth, and structurally sound—any shortcuts here will compromise the entire system. Next, our skilled installers carefully unroll and position the large EPDM sheets, making precise cuts to fit your roof’s unique dimensions. The real craftsmanship is demonstrated when the membrane is secured using one of three proven methods, followed by the expert application of primers and seam tapes to create the critical, monolithic watertight seams that will protect your building for decades.

Several factors influence your project’s final cost, and understanding them helps you make informed decisions. Labor costs are a significant component and vary based on your geographic location, the complexity of the job, and the installation method you choose. Building size and shape play a major role; larger, simple rectangular roofs benefit from economies of scale, while smaller or more complex roofs with numerous HVAC units, skylights, and penetrations require more custom cutting and detailed flashing work, increasing labor time.

Three Proven Installation Systems

When installing EPDM commercial roofing, you have three time-tested methods to choose from. Each has distinct advantages and is best suited for different building types, budgets, and performance requirements.

The Fully Adhered System is the premium choice for long-term performance and aesthetics. In this method, the EPDM membrane is completely bonded to the approved substrate (typically a cover board) using specialized adhesives. This creates a smooth, sleek, monolithic surface that is highly resistant to wind uplift—a crucial feature for buildings in Alabama’s storm-prone coastal areas. It is lightweight and offers superior flexibility for accommodating building movement. We often recommend this system for high-profile buildings, roofs with complex designs, or those with numerous penetrations. The trade-offs are a higher labor cost and a need for meticulous surface preparation and specific ambient temperatures for optimal adhesive curing.

The Mechanically Fastened System offers a balance of performance and cost-efficiency. Here, the membrane is secured to the roof deck using specialized fasteners and plates placed within the seam area. The adjacent sheet is then overlapped and sealed with seam tape, concealing the fasteners from the elements. This method is typically faster to install and less expensive than a fully adhered system because it requires less adhesive. It’s an excellent choice for large, open roof areas on steel or wood decks. Potential downsides include the possibility of small thermal bridges at fastener points and minor membrane billowing (‘flutter’) in high winds if not properly tensioned, though this does not affect performance.

The Ballasted System is the original and often most cost-effective EPDM installation method. In this approach, large EPDM sheets are loosely laid over the insulation boards. The entire system is then held in place by a layer of ballast, which is typically smooth, river-washed stone (at a rate of 10-12 pounds per square foot) or large concrete pavers. This method is fast to install and offers outstanding resistance to wind uplift, hail, and punctures due to the protective ballast layer. The ballast also adds thermal mass, which can help moderate building temperatures. The primary consideration is weight; the roof structure must be certified by an engineer to support the additional load, making ballasted systems ideal for robust structures like warehouses and distribution centers but unsuitable for many building types.

Understanding the Cost of EPDM Commercial Roofing

One of the most compelling advantages of EPDM commercial roofing is its reputation as one of the most cost-effective solutions for flat and low-slope roofs, especially when you factor in its impressive 30- to 50-year lifespan. However, the final price of your roofing project is influenced by several key variables.

Material costs are primarily driven by your choice of membrane thickness. A 45 mil membrane has the lowest upfront cost, 60 mil offers the industry-standard sweet spot of durability and value, and 90 mil provides maximum protection for a premium price. Labor rates vary across Alabama and are heavily dependent on your chosen installation method—ballasted systems are generally the fastest and least labor-intensive, while fully adhered systems demand the most skilled labor and time.

Your building’s specific characteristics significantly impact pricing. Large, open roofs benefit from economies of scale, reducing the per-square-foot cost. Conversely, roofs with numerous HVAC units, vents, pipes, skylights, or complex architectural features require extensive, time-consuming flashing work. Roof accessibility is another factor; if our crews need cranes, man-lifts, or extensive safety rigging to access your roof, these operational costs will be reflected in the project total. The condition of the existing roof also matters—a full tear-off and disposal of the old roof will cost more than a re-roof application over a suitable existing surface.

Warranty options provide choices for long-term protection. Manufacturers like Carlisle, Firestone, and GenFlex offer warranties ranging from 10 to 30 years. A more comprehensive, full-system No Dollar Limit (NDL) warranty, which covers both materials and workmanship, will increase your upfront investment but provides invaluable peace of mind.

Rather than providing generic estimates, we believe in delivering transparent, detailed quotes after a thorough inspection of your commercial property. Every roof has a unique story, and we are committed to ensuring your EPDM commercial roofing solution aligns perfectly with your budget and long-term performance goals. For business owners along the Gulf Coast, our expert team in Orange Beach, AL is ready to provide a comprehensive assessment and a detailed quote for your project.

Contact Our Orange Beach Commercial Roofing Experts

Prime Roofing & Restoration

Address: 25299 Canal Rd suite b-7, Orange Beach, AL 36561

Phone: (251) 210-2671

How to Get 50+ Years From Your EPDM Roof: Maintenance & Repairs

When you invest in EPDM commercial roofing, you are making a strategic decision to protect your building for decades. The performance data is clear: properly installed and maintained EPDM roofs consistently deliver 30 to 50 years of reliable service, with many examples lasting even longer. This isn’t just a manufacturer’s claim; it’s a fact backed by extensive real-world performance data and independent studies that have tracked EPDM roofs over their entire life cycle.

Consider the long-term financial impact: while other roofing systems might require a costly full replacement every 15-20 years, your single EPDM roof could outlast two or even three generations of those competing materials. This exceptional longevity translates directly into a lower total cost of ownership, fewer operational disruptions for your business, and greater budget predictability over the long run.

The secret to unlocking this impressive 50-year potential is surprisingly simple: proactive, preventative maintenance. Just like any other major building asset, your EPDM roof performs best when it receives regular, scheduled attention. This involves conducting routine inspections, ensuring drainage systems are clear, maintaining seam integrity, and addressing any minor damage promptly before it can escalate into a larger, more expensive problem.

Compelling evidence from the roofing industry supports this approach. The EPDM Roof Longevity Study by the EPDM Roofing Association (ERA) analyzed roofs that had been in service for over 30 years and found them still performing as intended. The key differentiator for the longest-lasting roofs was a consistent history of care. For comprehensive guidance on creating a proactive strategy to protect your investment, our commercial roof maintenance program resource covers everything a property owner needs to know.

Simple Repairs and Long-Term Care

One of the most appreciated features of EPDM commercial roofing is how straightforward it is to maintain and repair. Unlike complex multi-ply systems that require specialized tools or hazardous materials like hot asphalt, most EPDM repairs can be completed quickly, cleanly, and cost-effectively by a qualified technician.

Regular cleaning and inspection form the foundation of any good EPDM maintenance plan. EPDM’s smooth surface naturally resists dirt accumulation and the growth of moss or algae, making this task relatively easy. A semi-annual inspection, typically in the spring and fall, is recommended. During this walkthrough, debris like leaves, branches, and trash should be removed from the roof surface and cleared from all drains, scuppers, and gutters to prevent standing water, which can accelerate wear and add unnecessary stress to the structure.

Professional inspections every 1-3 years provide a deeper level of assessment. A certified technician will meticulously examine all seams, flashing details around penetrations, and the roof perimeter for any early signs of wear, such as small tears, punctures, or sealant deterioration. Catching these minor issues early allows for simple, inexpensive repairs that prevent major water intrusion events down the road.

When repairs are necessary, they are typically manageable. Small punctures or cuts from dropped tools or flying debris can be permanently patched using specialized EPDM repair kits. The process is clean and efficient: the technician cleans the damaged area with a weather-treated wipe, applies a specialized primer to the membrane, and then adheres a self-adhering EPDM patch over the puncture, rolling it firmly to ensure a watertight seal. Seam repairs are equally straightforward, often involving cleaning the seam, applying primer, and then applying a strip of pressure-sensitive cover tape to restore the monolithic, watertight seal.

For older roofs showing signs of widespread aging, liquid-applied EPDM coatings can be an excellent restoration option, extending the roof’s life for another 10-15 years at a fraction of the cost of a full replacement. For detailed, step-by-step guidance on handling common maintenance tasks and repairs, our comprehensive EPDM Roof Repair Guide provides valuable insights for property managers.

How EPDM Compares to TPO and Other Systems

While EPDM commercial roofing is an outstanding choice, we believe an informed client is the best client. When property owners compare EPDM to other popular flat roofing systems like TPO (Thermoplastic Polyolefin), PVC (Polyvinyl Chloride), and Modified Bitumen, several key differences emerge that often highlight EPDM’s superior long-term value.

Proven Track Record vs. Evolving Formulations: EPDM’s greatest advantage is its nearly 60-year history of real-world performance with a consistent chemical formulation. This extensive track record provides unmatched confidence in its longevity. TPO, a newer technology, has undergone several formulation changes over the years to improve performance, meaning its long-term durability is not as well-documented as EPDM’s.

Seam Technology: EPDM systems utilize advanced tape-based seams that create a powerful, flexible, and durable chemical bond. This technology is highly reliable and less sensitive to installer technique or environmental conditions. In contrast, thermoplastic systems like TPO and PVC rely on heat-welded seams. While strong when done perfectly, these welds can be compromised by inexperienced installers, inconsistent power sources, or surface contamination, potentially leading to seam failures over time.

Cold-Weather Flexibility and Durability: As a thermoset material, EPDM is cured during manufacturing, giving it exceptional stability and flexibility in extreme temperatures. It does not become brittle in freezing weather, maintaining its elasticity down to -120°F. This prevents cracking and splitting during the temperature swings common in the Alabama climate. Some thermoplastic materials can become more rigid in the cold, making them more susceptible to damage from impacts or building movement.

Puncture and Hail Resistance: While both EPDM and TPO offer good puncture resistance, EPDM’s rubbery, elastic nature gives it a distinct advantage in absorbing the impact of hail and other objects without fracturing. Thicker EPDM membranes (60 and 90 mil) are renowned for their ability to withstand severe hail events.

UV Resistance: Black EPDM’s formulation, rich with carbon black, provides unparalleled, time-tested resistance to UV degradation. While modern TPO formulations have greatly improved their UV resistance, EPDM’s 60-year history of success under the most intense sun provides a level of assurance that is hard to match.

When we analyze long-term value, EPDM consistently proves to be a wise investment. While its initial installed cost may be comparable to other single-ply systems, EPDM’s significantly longer average lifespan, simpler maintenance requirements, and proven durability translate to a lower total cost of ownership over the life of your building. This combination of a proven track record, robust performance, and financial value makes EPDM a smart, dependable choice for Alabama commercial properties that require reliable protection for decades to come.