Why Finding the Right Commercial Rubber Roofing Contractor is Critical for Your Business

When searching for commercial rubber roofing contractors near me, you’re not just looking for a service provider; you’re seeking a long-term partner to protect one of your most significant business assets. The right contractor is the crucial difference between a durable EPDM rubber roofing system that performs for 50+ years and a faulty installation that fails prematurely. A subpar roof can lead to catastrophic consequences, including inventory loss, operational shutdowns, hidden structural damage from water intrusion, and costly mold remediation—all of which can disrupt your business and erode your bottom line.

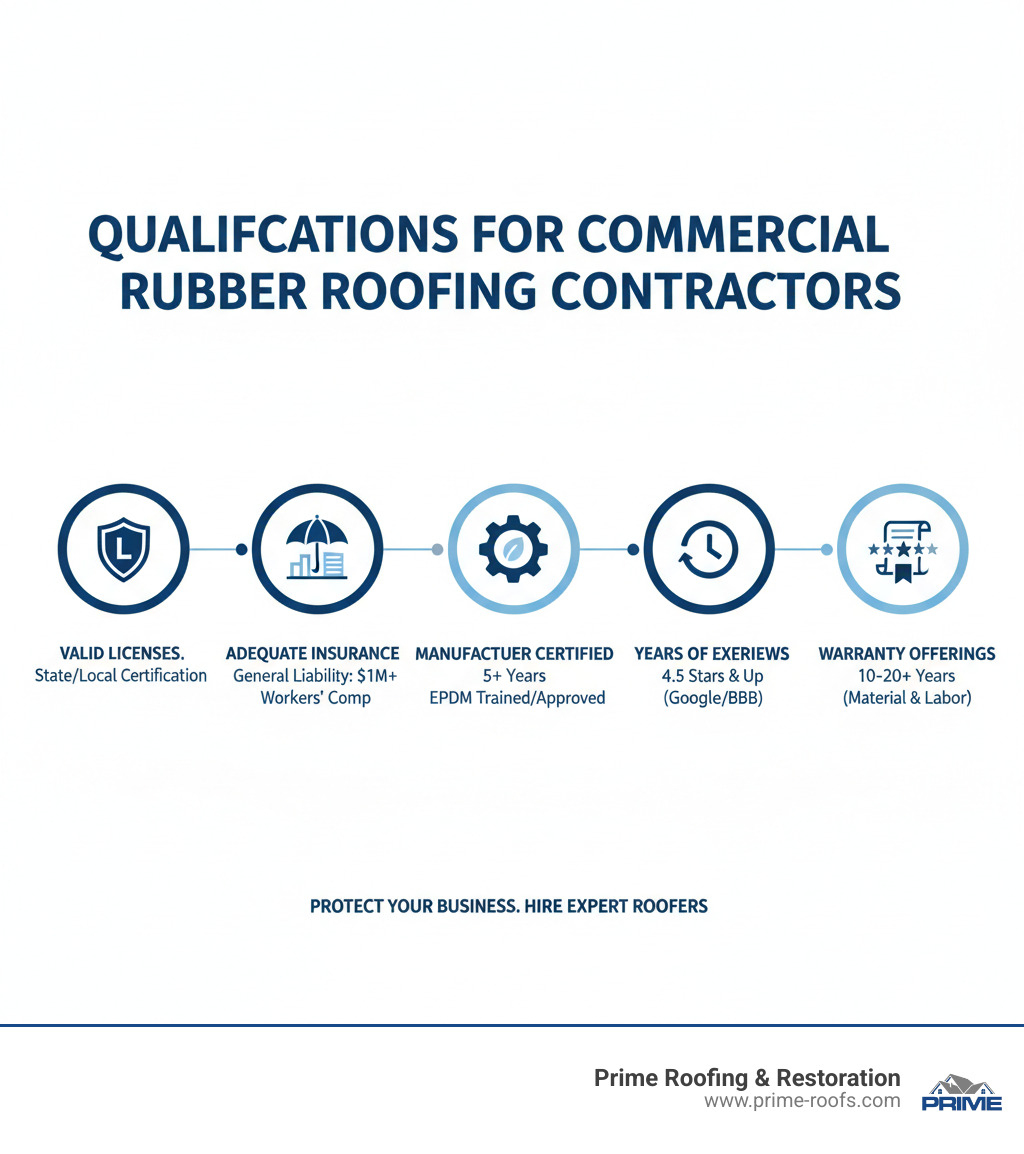

Quick Answer: What to Look for in Commercial Rubber Roofing Contractors Near Me:

- Valid Licensing and Insurance: This is non-negotiable. Verify their state license and ask for proof of both general liability insurance and worker’s compensation. This protects your property, their workers, and your business from liability.

- EPDM Manufacturer Certifications: Top-tier contractors hold certifications from leading manufacturers like Carlisle, Firestone, or Mule-Hide. This proves they have undergone specialized training and are authorized to install systems and offer the best warranties.

- Extensive Local Experience: A contractor familiar with Alabama’s climate understands the specific challenges posed by intense summer heat, high humidity, and severe storm seasons. This knowledge informs material selection and installation techniques.

- Proven Track Record & Portfolio: Ask to see a portfolio of recently completed commercial projects similar to yours. Reputable contractors will have a gallery of their work and a list of references you can contact.

- Comprehensive Warranties: Look for robust warranties that cover both materials (from the manufacturer) and labor (from the contractor). A strong workmanship warranty is a sign of a contractor’s confidence in their installation quality.

- Detailed Written Estimates: A professional estimate is itemized and transparent. It should clearly break down all costs for materials, labor, permits, tear-off, and debris disposal, leaving no room for surprise charges.

When a commercial property owner faces roofing challenges, time is money. As one industry expert noted, “A fire at Port Perry Hospital in 2017 caused over 10 million in damage,” highlighting how critical a properly installed and maintained roofing system is for business continuity and risk mitigation. A compromised roof can turn a manageable incident into a devastating financial loss.

The stakes are incredibly high when selecting commercial roofing services for your property. EPDM rubber roofing systems are engineered to last over half a century, but this potential is only unlocked when you choose contractors with the right experience, credentials, and commitment to excellence.

I’m Bill Spencer, Owner and President of Prime Roofing & Restoration. With over five years of dedicated experience helping Alabama businesses find reliable commercial rubber roofing contractors near me, our dual-location company proudly serves the Gulf Coast region. My hands-on expertise in flat roof systems, particularly EPDM installations, has been instrumental in building our A+ BBB rating and our reputation for delivering commercial roofing solutions that stand the test of time and weather.

Why EPDM Rubber Roofing is a Smart Investment for Your Business

When experienced commercial rubber roofing contractors near me recommend EPDM systems, they are endorsing one of the most proven and reliable roofing solutions in the industry. EPDM, which stands for ethylene propylene diene terpolymer, is a high-performance synthetic rubber membrane that has built an unparalleled reputation over decades of exceptional performance on commercial buildings worldwide.

What makes EPDM such a standout choice? It represents a powerful combination of extreme durability, long-term cost-effectiveness, and minimal maintenance requirements, creating a wise investment that pays dividends for years. When you choose commercial roofing services that specialize in EPDM installation, you’re investing in a system engineered to protect your property for over 50 years.

The weather resistance of EPDM is truly remarkable. This material is formulated to withstand Alabama’s unpredictable weather, from torrential spring rains and intense summer UV radiation to the occasional ice storm. A key advantage is its incredible flexibility. The membrane can expand and contract with daily and seasonal temperature fluctuations without becoming brittle or cracking—a common failure point for more rigid roofing materials. This elasticity ensures the roof maintains its integrity through years of thermal cycles.

Consider the longevity for a moment. A properly installed EPDM system lasting over 50 years means you may never face the expense and disruption of a roof replacement again during your business’s lifespan. That’s half a century of reliable, worry-free protection. This durability is complemented by low maintenance needs, which translate to fewer service calls, less disruption to your operations, and more capital staying in your budget where it belongs.

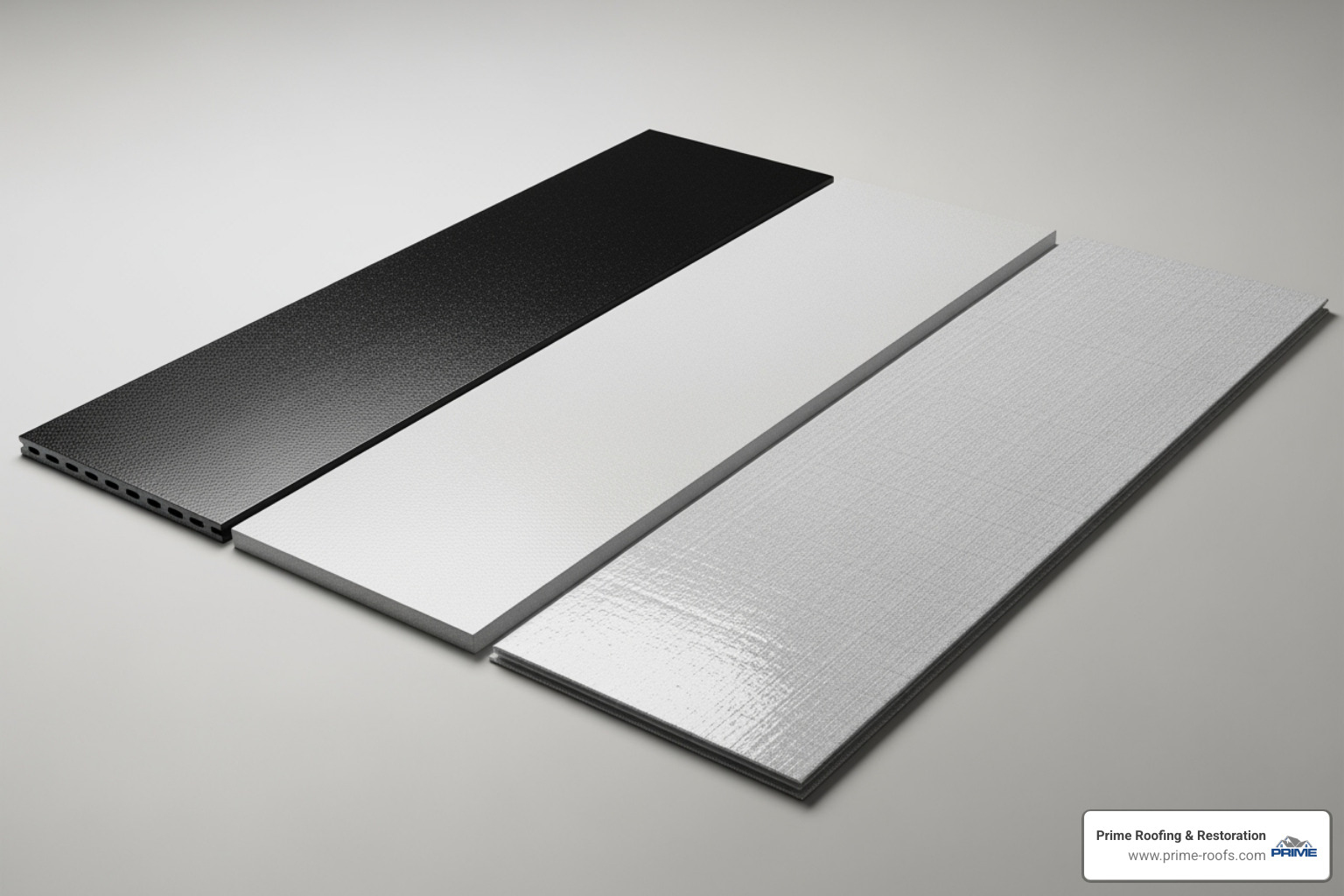

For businesses focused on energy efficiency, EPDM delivers tangible results. While traditional black EPDM is excellent for absorbing heat in colder climates, modern formulations include white EPDM, which is highly reflective. This “cool roof” technology reflects a significant portion of the sun’s UV rays, keeping the building cooler and reducing the load on HVAC systems during Alabama’s hot summers. To learn more about these benefits, you can explore resources from the Cool Roof Rating Council (CRRC).

The Financial and Environmental Advantages

Here’s where EPDM truly shines—on your bottom line. The superior insulation and reflective properties of a properly installed rubber roofing system can significantly reduce your building’s energy consumption. This leads to noticeable decreases in monthly heating and cooling costs. Many of our clients report seeing a positive impact on their utility bills within the first year of installation.

The return on investment (ROI) is exceptional when you analyze the total cost of ownership. While the initial installation is a capital expense, the combination of substantial energy savings, minimal maintenance costs, and an incredible 50+ year lifespan creates a powerful financial advantage that compounds over time. Some studies show that EPDM systems can pay for themselves in as little as seven years through energy savings alone.

From an environmental perspective, EPDM roofing is a leader in sustainability. The membrane is often manufactured using recycled materials, including post-consumer products, which diverts waste from landfills. Even more impressively, EPDM is fully recyclable at the end of its extensive service life. The old membrane can be repurposed into new roofing materials or other products, creating a closed-loop system that aligns with a circular economy.

Here’s a statistic that might surprise you: some recycled rubber roofing applications can divert the equivalent of 250-1000 tires from landfills per average roof installation. When you choose EPDM, you’re not just protecting your business investment—you’re making a positive environmental impact that extends far beyond your property lines. It’s a decision that benefits both your finances and the planet.

Rubber Roofing vs. Other Flat Roof Systems

While EPDM is a leading material for commercial flat roofs, a knowledgeable contractor will help you understand how it compares to other common systems. Each material has a unique profile of strengths and weaknesses, and the best choice depends on your specific building’s use, your budget, and the local climate. When commercial rubber roofing contractors near me assess your property, they’ll typically discuss three main single-ply membrane options: EPDM (Ethylene Propylene Diene Monomer), TPO (Thermoplastic Polyolefin), and PVC (Polyvinyl Chloride). It’s also helpful to compare them to older systems like Modified Bitumen.

| Feature | EPDM (Ethylene Propylene Diene Monomer) | TPO (Thermoplastic Polyolefin) | PVC (Polyvinyl Chloride) | Modified Bitumen |

|---|---|---|---|---|

| Lifespan | Up to 50+ years with proper maintenance | 20-30 years | 20-30+ years | 10-20 years |

| Cost | Generally lower initial cost | Moderate initial cost | Higher initial cost | Moderate to high cost |

| Durability | Excellent resistance to UV, ozone, and extreme weather; highly flexible | Good resistance to punctures, tears, and chemicals; heat-weldable seams | Superior chemical resistance, fire resistance, and seam strength | Excellent puncture and tear resistance due to multiple layers |

| Installation | Mechanically fastened, fully adhered, or ballasted | Heat-welded seams for strong bonds | Heat-welded seams for strongest bonds | Torch-applied, self-adhered, or hot-mopped; more labor-intensive |

| Energy Eff. | Dark surface absorbs heat (can be reflective if white-coated) | Typically white or light-colored, highly reflective, excellent energy efficiency | White or light-colored, highly reflective, excellent energy efficiency | Can be coated with reflective granules for moderate energy efficiency |

| Recyclability | Often made from recycled materials and fully recyclable | Recyclable | Recyclable | Difficult to recycle; often ends up in landfills |

EPDM stands out for its unmatched longevity and flexibility. It’s the marathon runner of roofing materials, built to endure for half a century. Its rubber composition allows it to flex and move with a building’s natural expansion and contraction, preventing cracks and splits, which is especially valuable in climates with wide temperature swings. EPDM installation is versatile: it can be ballasted (held down with rocks), mechanically fastened, or fully adhered, offering solutions for different structural and budget requirements.

TPO has become the fastest-growing segment in commercial roofing, largely due to its energy efficiency and competitive cost. Its standard bright white surface is highly reflective, bouncing solar radiation away from the building and significantly lowering cooling costs in hot climates like Alabama. The seams are heat-welded, creating a monolithic, waterproof surface that is very strong. While early formulations had some issues, modern TPO is a reliable and popular choice for many businesses.

PVC offers premium performance, especially in challenging environments. Its key advantage is superior resistance to chemicals, grease, and oils, making it the ideal choice for restaurants, manufacturing plants, and airports where roof exposure to such substances is a concern. Like TPO, its seams are heat-welded for maximum strength and water tightness. While it has a higher upfront cost, its durability in harsh conditions provides excellent long-term value.

Modified Bitumen is an asphalt-based system that has been around for decades. It is known for its toughness and puncture resistance, thanks to its multi-ply construction. However, it has a shorter lifespan than single-ply membranes, is more labor-intensive to install (often requiring torches or hot asphalt), and is less environmentally friendly. While still used in some applications, many building owners are moving toward more modern, energy-efficient, and sustainable options like EPDM, TPO, or PVC.

The best choice depends on a thorough evaluation of your building’s structure, its daily operations, your long-term business goals, and your budget. A professional consultation can help you navigate these options to ensure you make the most informed decision for your property.

How to Find the Best Commercial Rubber Roofing Contractors Near Me

Choosing the right contractor is the single most important decision you’ll make for your roofing project. A flawless installation by a skilled team is what unlocks the 50-year potential of a high-quality rubber roof. When you search for commercial rubber roofing contractors near me, you need to identify a true partner with proven expertise, a steadfast commitment to quality, and deep local knowledge. A roof is not just a building component; it’s the primary shield protecting your entire business operation from the elements.

Think of it this way: you wouldn’t hire a general practitioner for specialized heart surgery. The same principle applies to commercial roofing. The difference between a certified EPDM specialist and a general roofer can mean decades of worry-free protection versus years of leaks, repairs, and costly headaches. Experience matters tremendously. A contractor who has successfully installed hundreds of thousands of square feet of commercial rubber roofing will anticipate challenges and masterfully handle the complex details around HVAC units, drains, parapet walls, and roof penetrations that are critical to a roof’s long-term performance.

Vetting Your Local Commercial Rubber Roofing Contractors: A Step-by-Step Guide

Step 1: Verify Credentials (The Non-Negotiables)

Start by confirming that any potential contractor is fully licensed and insured. You can verify a contractor’s license through the Alabama Licensing Board for General Contractors. This is a non-negotiable first step. An uninsured contractor exposes your business to immense financial risk, potentially leaving you liable for accidents or property damage. Ask for a Certificate of Insurance (COI) directly from their insurance provider, ensuring it lists both general liability and worker’s compensation coverage.

Step 2: Look for Manufacturer Certifications

Next, look for certifications from leading EPDM manufacturers like Carlisle, Firestone, or Johns Manville. These certifications are not easily earned; they indicate that the contractor’s team has undergone rigorous, specialized training and is authorized to install roofing systems to the manufacturer’s exact specifications. This is often a prerequisite for obtaining the best long-term material warranties. For example, the CertainTeed Select ShingleMaster Certification is awarded to the top 1% of contractors, a testament to superior workmanship and customer satisfaction. You can learn more about checking contractor qualifications to understand what these credentials truly signify.

Step 3: Check Reviews and Request a Portfolio

Dive into online reviews on platforms like Google, the BBB, and industry-specific sites. Look for patterns in feedback related to communication, professionalism, and post-installation support. Go beyond reviews by asking for a portfolio of past commercial projects and a list of local references. A contractor with deep roots in the community, like those serving the local Alabaster, AL area, will have a proven track record and understand the nuances of local building codes and weather challenges.

Key Questions to Ask Commercial Rubber Roofing Contractors Near Me

To ensure you’re hiring the best team, come to the consultation prepared with specific questions. A reputable contractor will appreciate your diligence.

- Experience & Specialization: “How many years have you specialized in EPDM rubber roofing? Can you provide references for three local commercial projects of a similar size completed in the last two years?”

- Materials & Methods: “What manufacturer’s EPDM do you recommend for my building and why? What membrane thickness (e.g., 60-mil, 90-mil) do you suggest? Will you be fully adhering, mechanically fastening, or ballasting the membrane, and what are the pros and cons of that method for my roof?”

- Project Management: “Who will be my single point of contact during the project? How will you protect my property, landscaping, and customers during the installation? What is your process for daily cleanup?”

- Detail Work: “How do you handle flashing around penetrations like pipes, vents, and HVAC units to ensure a permanent, watertight seal?”

- Warranties: “Please explain the warranties you offer. What is covered under the manufacturer’s warranty versus your workmanship warranty? Is the warranty transferable?”

- Safety: “What are your company’s safety protocols? Are your employees OSHA-trained and certified?”

- Business Continuity: “How will you minimize disruption to my business operations? Can you accommodate work during off-hours or weekends if necessary?”

- The Quote: “Will you provide a detailed, itemized quote that breaks down all costs, including materials, labor, permits, and waste disposal?”

A transparent and professional contractor will provide clear, detailed answers and a comprehensive written quote. We believe in providing solutions that are not only effective but also offer excellent value, ensuring your roof meets all local building codes and safety standards. Your search for commercial rubber roofing contractors near me should end with a trusted partner, not just a service provider.

The Rubber Roofing Lifecycle: Installation, Maintenance, and Replacement

Understanding the complete lifecycle of a commercial rubber roof—from the details of installation to proactive maintenance and eventual replacement—is key to maximizing your investment. A commercial roof is a long-term asset, and knowing what to expect at each stage empowers you to make smart decisions that protect your business for decades to come.

The Commercial Rubber Roof Installation Process

A high-performance roof is built on a high-performance installation. Here’s a typical step-by-step look at what a professional installation entails:

- Initial Tear-Off and Substrate Inspection: In most cases, the old roofing material is removed down to the structural deck. This allows the crew to thoroughly inspect the underlying substrate for any rot, damage, or moisture and make necessary repairs.

- Insulation and Underlayment: New, high-R-value insulation boards (like Polyisocyanurate) are installed. This is a critical step for energy efficiency. A cover board may be added on top to provide a smooth, durable surface for the membrane.

- Membrane Installation: The large sheets of EPDM membrane are rolled out. Depending on the project, they will be installed using one of three methods: fully adhered (glued down for maximum wind uplift resistance), mechanically fastened (attached with plates and screws), or ballasted (held in place with a layer of smooth river rock).

- Seam Treatment: The seams where the EPDM sheets overlap are meticulously cleaned and sealed using specialized primers and seam tape. This process creates a strong, waterproof bond that is critical to the roof’s integrity.

- Flashing and Detail Work: This is where expertise truly shows. The crew creates custom flashing around all roof penetrations—pipes, vents, drains, skylights, and HVAC units—to ensure every potential entry point for water is sealed.

- Final Inspection and Cleanup: The project manager conducts a final walkthrough to inspect every seam and detail, ensuring the installation meets manufacturer specifications. The site is then thoroughly cleaned of all debris.

What is the Typical Cost of a Rubber Roof?

The cost of a commercial rubber roof installation can range from $5 to $12 per square foot, but this varies based on several key factors. Project size is a major driver, as larger roofs often have a lower cost per square foot. The condition of the existing roof is also crucial; a full tear-off and substrate repair will cost more than a simple overlay. Other factors include:

- Material Quality: Thicker membranes (e.g., 90-mil vs. 60-mil) and specialized white EPDM cost more upfront but offer greater durability and energy savings.

- Insulation Choice: The type and thickness of insulation will impact the final price and the building’s long-term energy performance.

- Roof Complexity: A roof with numerous HVAC units, pipes, and vents requires more detailed labor, increasing the cost.

- Warranty Level: Enhanced, long-term warranties from the manufacturer often require specific installation standards and materials, which can affect the price.

We always provide a detailed estimate that breaks down all associated costs, ensuring complete transparency so you know exactly where your investment is going.

What Maintenance is Required for Commercial Rubber Roofing?

One of EPDM’s most attractive features is its low-maintenance nature. However, proactive care is essential to achieving that 50+ year lifespan. We recommend a professional inspection twice a year (spring and fall) to perform the following:

- Debris Removal: Clear away leaves, branches, and other debris that can clog drains and hold moisture against the roof surface.

- Seam and Flashing Inspection: Carefully check all seams and flashing around penetrations for any signs of pulling, separation, or deterioration.

- Membrane Surface Check: Look for any punctures, tears, or blisters. Small punctures from dropped tools or storm debris are the most common repair need.

- Drain and Gutter Cleaning: Ensure all drainage pathways are clear to prevent pooling water.

Promptly addressing small issues is the secret to avoiding large, expensive problems. A minor puncture repair might cost a few hundred dollars, but ignoring it could lead to thousands in water damage and mold remediation. Our detailed EPDM Roof Repair Guide provides more insight into common issues and solutions.

Signs Your Commercial Roof Needs Repair or Replacement

Even the most durable roof will eventually need attention. Be vigilant for these warning signs:

- Visible Punctures, Tears, or Cracks: Any breach in the membrane is an immediate threat.

- Bubbling or Blistering: This indicates that moisture is trapped between the membrane and the substrate.

- Seams Pulling Apart: Failed seams are a primary cause of major leaks.

- Pooling Water: Water that remains on the roof for more than 48 hours after rainfall indicates a drainage problem and will accelerate the aging of the membrane.

- Interior Water Stains: The most obvious sign that a leak has already occurred.

If your roof is approaching the end of its expected lifespan (25+ years), damage is widespread, or repair costs are becoming frequent, a full commercial roof replacement is often the most cost-effective long-term solution. A professional inspection can provide a clear assessment to help you decide whether to repair or replace, ensuring you invest your money wisely.

Your Trusted Roofing Partner in Alabaster, AL

When your search for commercial rubber roofing contractors near me leads you to us, you’ll find that the relationship we build matters just as much as the materials we use. For businesses in Alabaster, Pelham, and the surrounding Alabama communities, having a dedicated, local team ready to respond is essential for protecting your investment and ensuring business continuity.

At Prime Roofing & Restoration, we don’t see your commercial roof as just another project—it’s the shield that protects your inventory, your employees, and your entire livelihood. This perspective is why we’ve built our reputation on forging lasting relationships rather than completing one-time transactions. When you call us for an emergency repair after a storm or need expert guidance on navigating a complex insurance claim, we are here with the same unwavering commitment and expertise you experienced on day one.

Our approach is comprehensive. We begin by using only high-quality materials from trusted manufacturers, ensuring your EPDM installation meets or exceeds the highest industry standards. But what truly sets us apart is our 24/7 emergency service, staffed by licensed experts who intimately understand the unique challenges Alabama weather can inflict on a commercial property. From sudden hail damage and high winds to routine maintenance that prevents problems before they start, we are always on call to protect your business.

Prime Roofing & Restoration

Address: 5 Brown Cir, Alabaster, AL 35007

Phone: (205) 661-8190

What makes us different from other commercial rubber roofing contractors near me is our deep, practical understanding of local conditions. We know how Alabama’s intense summer heat and UV exposure can test a membrane’s durability. We know how our severe thunderstorms and occasional hurricanes on the Gulf Coast test seam strength and wind uplift resistance. This local expertise allows us to recommend and implement solutions that are genuinely engineered to last in our unique environment, not just generic approaches that might fail under local stresses.

When you partner with Prime Roofing & Restoration, you’re not just hiring a contractor; you’re gaining a dedicated team that is invested in your success and will be there to support you for the entire life of your roof.

Conclusion: Secure Your Property with an Expertly Installed Rubber Roof

A commercial rubber roof is a demonstrably superior choice for protecting your business, offering decades of reliable performance with remarkably minimal upkeep. The unmatched durability, significant energy efficiency, and positive environmental benefits of EPDM make it an incredibly smart, long-term investment for any forward-thinking commercial property owner. While others may face the recurring costs and disruptions of frequent roof repairs, you can enjoy the peace of mind that comes with a system designed to perform, year after year.

However, all of these powerful benefits hinge on one critical factor: the quality of the installation. The difference between a roof that achieves its 50+ year potential and one that fails within a decade is almost always the expertise of your chosen commercial rubber roofing contractors near me. A premium material is only as good as the hands that install it.

This is why it is imperative to vet your potential contractors thoroughly. Take the time to verify their state license and insurance, insist on seeing proof of manufacturer certifications, and always ask for a portfolio of local commercial projects. A confident, professional contractor will welcome these questions as an opportunity to demonstrate their qualifications and commitment to excellence.

When you partner with experienced professionals who master both advanced EPDM installation techniques and local Alabama building requirements, you are investing in decades of security for your business. A quality installation translates directly to fewer emergency calls, lower maintenance budgets, and the invaluable confidence that comes from knowing your property is shielded by a robust, professionally-engineered roofing system.

Prime Roofing & Restoration has built our A+ reputation on delivering this exact level of reliable, expert service. We understand that your commercial roof is not just another construction project—it is the shield protecting everything you have worked so hard to build. We focus on building lasting relationships with our clients, using only the best materials, and providing the responsive, 24/7 service that keeps your business running smoothly and securely.

Ready to secure your commercial investment for the long haul? Explore our expert Commercial Roofing Services to learn more, or contact us today to schedule a comprehensive, no-obligation roof inspection and receive a free, detailed estimate. Your business deserves the ultimate protection that only an expertly installed commercial rubber roof can provide.