Why Warehouse Roof Replacement Protects Your Bottom Line

Warehouse roof replacement is a critical infrastructure investment that safeguards your inventory, equipment, and business operations from costly damage. When your commercial roof reaches the end of its 20-30 year lifespan or shows signs of significant deterioration, replacement becomes the most cost-effective long-term solution. For guidance custom to your facility, consult our local commercial roofing experts—the team at Prime Roofing & Restoration can guide you through the entire process.

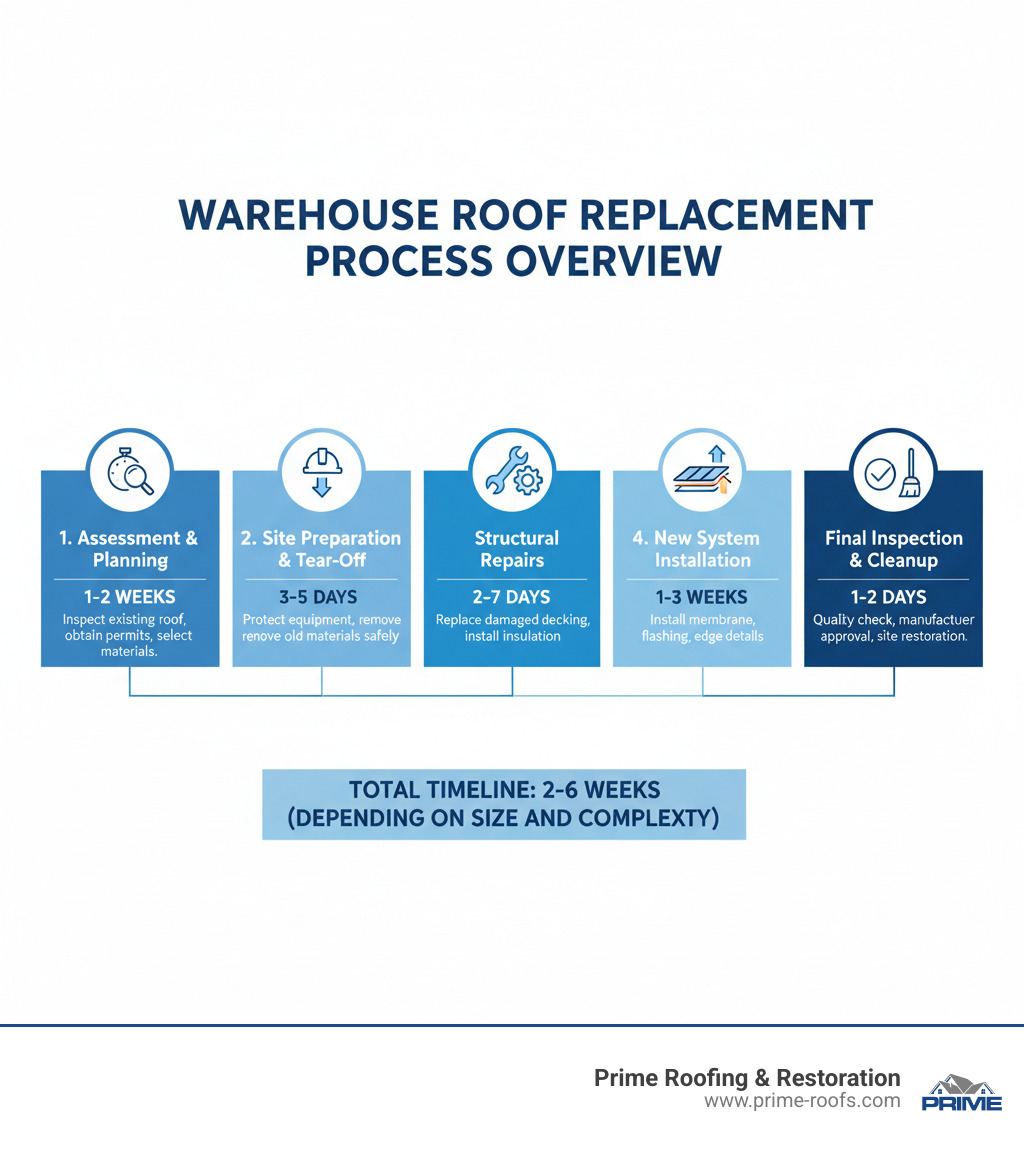

Essential steps for preparing for warehouse roof replacement:

- Assess the roof condition – Schedule a professional inspection to document damage, leaks, and structural issues

- Select appropriate materials – Choose between TPO, EPDM, metal, or built-up roofing based on budget and building needs

- Budget for total costs – Plan for $50,000 to $200,000+ depending on size, materials, and complexity

- Choose a qualified contractor – Verify licensing, insurance, and commercial roofing experience

- Plan for minimal disruption – Coordinate phased work schedules to maintain warehouse operations

- Understand warranties – Secure both manufacturer material warranties (10-30 years) and workmanship guarantees

- Schedule regular maintenance – Implement bi-annual inspections to maximize your new roof’s lifespan

According to industry data, commercial roof replacement costs typically range from $5 to $12 per square foot, with complex projects potentially exceeding $200,000. The average commercial roof lasts 20-30 years with proper maintenance, making timely replacement essential to avoid catastrophic failure that could damage your entire facility.

Roughly 30% of a building’s structure protects 100% of the people and assets inside, making your warehouse roof arguably your most critical building component. Ignoring warning signs or delaying replacement can lead to water damage, inventory loss, operational disruptions, and significantly higher emergency repair costs.

I’m Bill Spencer, owner of Prime Roofing & Restoration, and I’ve overseen warehouse roof replacement projects throughout Central Alabama for over five years, specializing in flat roof systems optimized for our region’s climate. Our team at Prime Roofing helps warehouse owners steer the entire replacement process, from initial assessment through commercial roof installation and long-term maintenance planning.

Warehouse roof replacement word roundup:

Is It Time for a Replacement? 7 Key Warning Signs

Your warehouse roof works hard every single day—shielding your inventory, protecting your equipment, and keeping your operations running smoothly. But like any hardworking asset, it won’t last forever.

A commercial roof’s typical lifespan is 20-30 years, but proactive assessment is crucial to prevent catastrophic failure. The difference between a planned replacement and an emergency repair can literally be hundreds of thousands of dollars. Ignoring early warning signs can lead to water-damaged inventory, operational shutdowns, and repairs that cost far more than a scheduled replacement would have.

A professional roof inspection can determine if repairs are sufficient or if a full replacement is the most cost-effective solution. At Prime Roofing & Restoration, we’ve seen warehouse owners save significant money simply by catching problems early and making informed decisions about repair versus replacement.

Here are seven key warning signs that your warehouse roof might be telling you it’s time for a change:

The age of your roof is often your first and most reliable indicator. Built-Up Roofing (BUR) and single-ply membranes like TPO and EPDM typically last 20-30 years, while metal roofs can push 40-70 years with proper care. If your roof is approaching or has passed its expected lifespan, it deserves a thorough professional assessment—even if everything looks fine from ground level. Age alone doesn’t mean immediate replacement, but it does mean you should be watching closely.

Persistent leaks are your roof’s way of waving a red flag. One isolated leak might just need a patch, but multiple leaks—especially after minor rainfall—signal widespread system failure. If you’re playing whack-a-mole with leaks that keep popping up in different areas despite repairs, your roof is likely failing across the board. These recurring leaks don’t just damage inventory; they create unsafe working conditions and can compromise your building’s structural integrity over time.

Visible membrane damage is exactly what it sounds like—problems you can actually see. Cracks, tears, blisters, punctures, or areas where the membrane looks brittle and dried out all indicate that your roof’s protective layer is breaking down. For gravel-surfaced roofs, watch for bare spots where the aggregate has worn away, exposing the underlying layers to harsh UV rays. Once the membrane is compromised, it’s no longer effectively sealing your building against rain, snow, and the elements.

Ponding water is a serious concern on any flat or low-slope commercial roof. Your roof should drain water efficiently—if you see standing water 48 hours after a rain event, that’s considered ponding, and it’s a problem. Ponding water accelerates material deterioration, promotes algae and plant growth, and creates structural stress that can lead to leaks and premature roof failure. Many manufacturer warranties specifically exclude damage caused by ponding water, so this issue can leave you unprotected.

Increased energy bills might seem unrelated to your roof, but they’re often directly connected. An aging or damaged roof loses its insulating properties over time. If your warehouse heating or cooling costs have steadily climbed without other clear explanations, your roof could be the culprit. Compromised insulation allows heat to escape in winter and pour in during summer, forcing your HVAC systems to work overtime and driving up your energy costs month after month.

Damaged flashing creates vulnerable entry points for water. Flashing is the material installed around roof penetrations—vents, skylights, HVAC units—and at roof edges to prevent water intrusion. Rusted, bent, or deteriorated flashing allows water to bypass your main roofing membrane and seep into your building. Damaged flashing is one of the most common sources of leaks and often signals that your entire roof system is aging and losing its effectiveness.

Structural sagging is the most severe warning sign and demands immediate attention. If you notice any visible sagging or deflection in your roof deck, you’re looking at a serious structural issue that could lead to partial or complete roof collapse. This might result from water saturation within the roof assembly, damaged structural components, or excessive loads. Sagging is never something to wait on—it requires professional evaluation right away.

When these warning signs become prevalent, routine maintenance and spot repairs are no longer enough. At that point, warehouse roof replacement becomes your most cost-effective path forward to protect your valuable assets and maintain operational integrity. The good news? Catching these signs early gives you time to plan, budget, and schedule your replacement on your terms rather than dealing with an emergency situation.

If you’re seeing any of these warning signs, contact Prime Roofing & Restoration for a thorough assessment. We’ll help you understand exactly what’s happening with your roof and what your best options are moving forward.

Choosing the Right System: Materials, Costs, and Considerations

Selecting the appropriate roofing system is the most critical decision in a warehouse roof replacement project. The choice impacts cost, longevity, energy efficiency, and maintenance requirements. Factors like structural design, drainage needs, and building use must be carefully evaluated.

The material you choose for your warehouse roof isn’t just about what looks good or costs least upfront. It’s a long-term investment that affects everything from your monthly energy bills to how often you’ll need maintenance crews on-site. Think of it as choosing the right foundation for decades of protection.

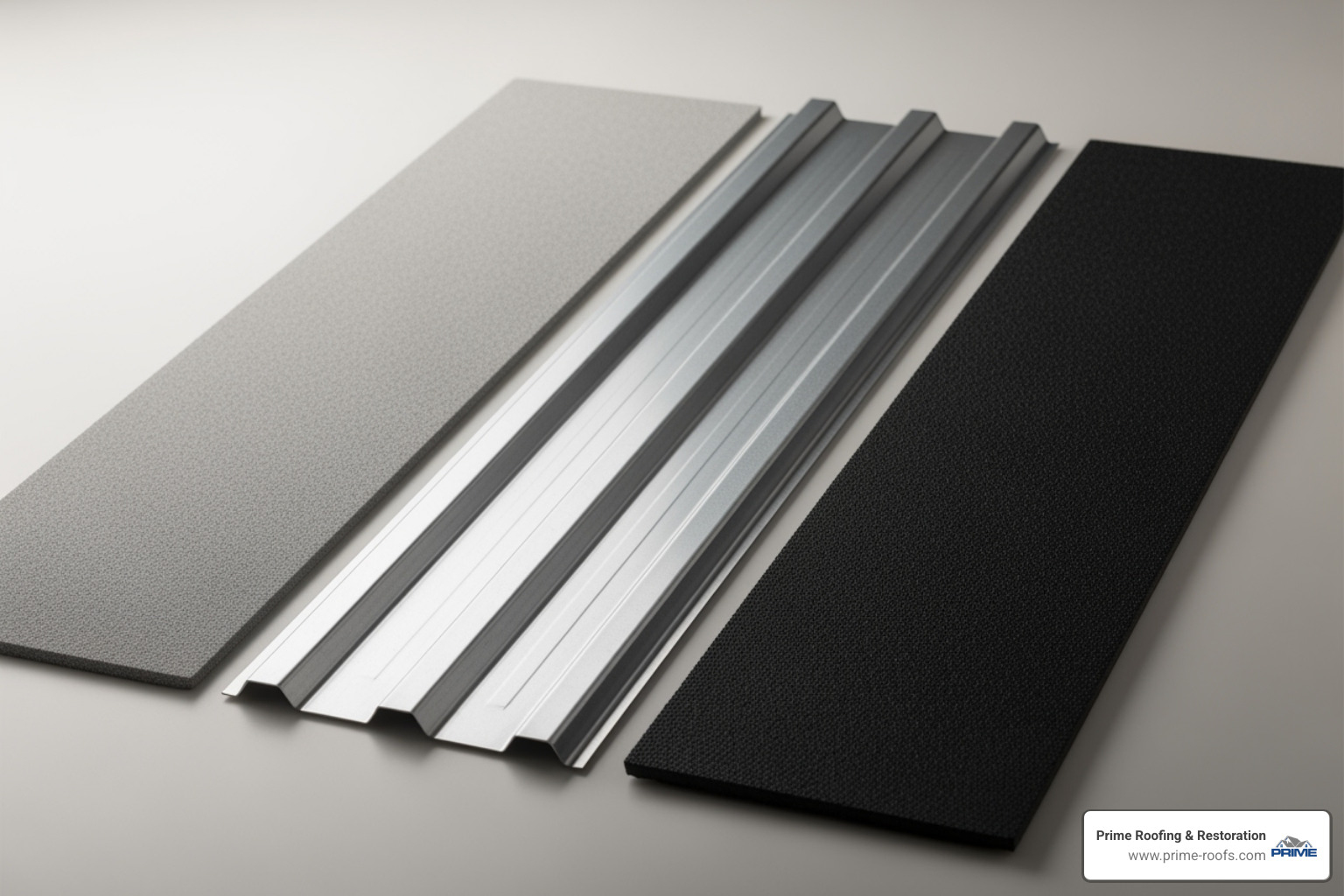

TPO (Thermoplastic Polyolefin) has become one of the most popular choices for warehouse roofs, and for good reason. With a lifespan of 15-30 years and costs ranging from $11-$14 per square foot, it offers solid value for budget-conscious warehouse owners. The bright white surface reflects sunlight beautifully, which translates directly to lower cooling costs during those brutal Alabama summers. The heat-welded seams create watertight bonds that hold up well against weather. The trade-off? TPO generally won’t last quite as long as some premium options like EPDM or metal.

EPDM (Ethylene Propylene Diene Monomer) is the workhorse of commercial roofing. This rubber membrane can last anywhere from 20 to 50 years when properly maintained, making it one of the most durable options available. At $11-$14 per square foot, it’s similarly priced to TPO but offers superior longevity. EPDM remains flexible even in cold weather and stands up remarkably well to UV exposure and temperature swings. The downside is that darker EPDM absorbs more heat than reflective materials, potentially increasing cooling costs. It’s also more vulnerable to punctures from sharp objects or heavy foot traffic.

Metal roofing represents the premium end of warehouse roofing, with lifespans reaching 40-70 years or even longer. While costs vary from $7-$15 per square foot depending on the metal type and profile, the initial investment pays dividends over decades of virtually maintenance-free performance. Metal roofs are extremely fire-resistant, an important consideration for warehouses storing valuable inventory or flammable materials. They shed water and snow efficiently and can support solar panel installations beautifully. The main considerations are higher upfront costs and potential noise during heavy rain (though proper insulation largely solves this).

Built-Up Roofing (BUR) is the traditional multi-layer system that’s been protecting commercial buildings for over a century. With a lifespan of 20-30 years and costs between $11.50-$14.50 per square foot, BUR offers proven reliability. Multiple layers of bitumen and reinforcing fabrics create exceptional waterproofing and UV resistance. However, BUR systems are heavy, requiring adequate structural support, and installation is labor-intensive, which can extend project timelines.

Beyond the basic material choice, your decision should factor in your warehouse’s specific needs. A refrigerated facility benefits enormously from reflective roofing that reduces cooling loads. A warehouse in a high-wind zone needs a system with superior wind uplift ratings. Buildings with rooftop HVAC equipment require materials that can handle regular foot traffic without damage.

The structural capacity of your existing building also plays a role. Older warehouses may not support the weight of certain systems without reinforcement. Your local climate matters too—some materials excel in hot, sunny conditions while others perform better in areas with freeze-thaw cycles.

Working with an experienced commercial roofing contractor helps you steer these choices. They can assess your building’s unique characteristics and recommend the system that delivers the best long-term value for your specific situation.

Factors Influencing Your Warehouse Roof Replacement Cost

The total cost of a warehouse roof replacement can range from $50,000 to over $200,000, depending on several key variables. Understanding these factors will help you budget effectively and compare quotes accurately.

Roof size and complexity is the most obvious cost driver. A simple 20,000 square foot flat roof costs far less than a 100,000 square foot facility with multiple levels, skylights, and rooftop equipment. Every penetration, every change in elevation, and every architectural detail adds labor hours and materials.

Your material choice directly impacts both immediate and long-term costs. While TPO might seem economical at $11-$14 per square foot, metal roofing at $7-$15 per square foot could actually cost less over its 40-70 year lifespan when you factor in fewer replacements. The key is balancing upfront investment with total lifecycle costs. For more details on budgeting, check out this comprehensive roof replacement cost guide.

Labor costs vary significantly by region and contractor experience. In Central Alabama, labor typically represents 40-60% of total project costs. Complex installations requiring specialized skills or equipment command premium rates, but the investment in quality workmanship prevents costly failures down the road.

Insulation and underlayment upgrades can add $2-$4 per square foot but dramatically improve energy efficiency and roof performance. Modern tapered insulation systems eliminate ponding water while boosting R-values, potentially cutting energy costs by 20-30% annually.

Structural repairs are often finded during tear-off and can significantly impact budgets. Water-damaged decking, compromised joists, or inadequate structural support must be addressed before installing new roofing. This is why thorough pre-project inspections are essential.

Code requirements have evolved considerably in recent years. Newer building codes may mandate improved fire ratings, higher wind uplift resistance, or improved insulation values. Bringing an older warehouse up to current standards adds costs but ensures compliance and improved performance.

Accessibility affects project efficiency and costs. A warehouse in a congested urban area with limited staging space costs more than a facility with ample surrounding room for material storage and equipment. Height and roof pitch also impact safety requirements and labor rates.

Improving Energy Efficiency and Drainage

A new roof is an opportunity to significantly lower your building’s operating costs. Modern “cool roof” materials like white TPO roofing can reflect sunlight and reduce cooling expenses by up to 25%, as documented by the U.S. Department of Energy. That’s real money back in your pocket every month, month after month, for decades.

Reflective materials work by bouncing solar radiation back into the atmosphere rather than absorbing it into your building. White TPO, light-colored metal, and specially coated membranes can maintain surface temperatures 50-60 degrees cooler than traditional dark roofs on hot summer days. This translates directly to reduced air conditioning loads and lower utility bills.

Tapered insulation systems serve double duty by improving both energy efficiency and drainage. By creating deliberate slopes on otherwise flat roofs, tapered insulation directs water toward drains and scuppers while eliminating ponding. The improved R-value keeps conditioned air inside your warehouse where it belongs, reducing heating costs in winter and cooling costs in summer.

Waterproofing membranes have advanced significantly in recent years. Modern single-ply systems and modified bitumen products offer superior water resistance while maintaining flexibility across temperature extremes. Properly installed membranes with heat-welded or chemically bonded seams create virtually impenetrable barriers against moisture intrusion.

Proper drainage is essential to prevent ponding water, which accelerates roof degradation and can void warranties. Most manufacturers require water to drain completely within 48 hours of rainfall. Gutters and downspouts sized appropriately for your roof area and local rainfall intensity keep water moving off and away from your building. Regular maintenance keeps these systems functioning properly.

Clean, functioning drains and scuppers prevent the weight stress and membrane degradation that ponding water causes. Even a few inches of standing water adds thousands of pounds of load to your roof structure while creating ideal conditions for leaks and biological growth.