Why TPO Roofing Companies Are Essential for Modern Commercial Properties

When it comes to protecting modern commercial properties, the expertise of professional TPO roofing companies is not just beneficial—it’s essential. These specialized contractors are the gatekeepers to one of the most advanced and popular roofing technologies available today. Thermoplastic Polyolefin (TPO) membrane systems have captured an impressive 40% of the commercial roofing market, a figure that speaks volumes about their performance and value. As a leading provider of comprehensive roofing solutions in Alabama, we’ve seen firsthand how these single-ply systems consistently deliver superior energy efficiency, long-term durability, and unmatched cost-effectiveness for the flat and low-slope roofs common on commercial and industrial buildings. The decision to install a TPO roof is a significant investment in your property’s future, and the success of that investment hinges almost entirely on the quality of the installation.

What to Look for in Premier TPO Roofing Companies:

Choosing the right contractor is a critical process that requires due diligence. Here’s a more detailed breakdown of what separates the experts from the amateurs:

-

Licensed and Insured Contractors with Manufacturer Certifications: Don’t just take their word for it. A reputable company will readily provide proof of their state license (like an Alabama Home Builders License) and comprehensive insurance, including general liability and worker’s compensation. Even more important are manufacturer certifications. Top-tier manufacturers like GAF, Carlisle, and Firestone offer rigorous training programs. A certified installer is not only proficient in the manufacturer’s specific installation guidelines but can also offer enhanced warranties, such as a No Dollar Limit (NDL) warranty, that cover both materials and workmanship.

-

Proven Experience with Diverse Installation Systems: TPO installation is not one-size-fits-all. Ask potential contractors about their experience with mechanically attached, fully adhered, and induction-welded systems. A seasoned company can assess your building’s structure, wind exposure, and budget to recommend the optimal method. They should be able to show you a portfolio of completed projects that showcase their versatility.

-

Heat-Welding Expertise for Superior Seam Strength: The single most critical aspect of a TPO installation is the heat-welding of the seams. This process creates a monolithic, permanent bond that is stronger than the membrane itself. It requires specialized equipment and technicians who know how to adjust for ambient temperature, humidity, and membrane temperature. Improperly welded seams are the number one cause of TPO roof failure, making this a non-negotiable area of expertise.

-

Comprehensive Warranties Covering Materials and Workmanship: A quality TPO roof is backed by two warranties: one from the manufacturer covering material defects and one from the contractor covering installation errors. The best TPO roofing companies offer robust workmanship warranties of 10 years or more, standing confidently behind their work. Be sure to read the fine print to understand what is covered and for how long.

-

Strong Local Reputation with Verified Customer Testimonials: Look for a company with deep roots in the local community. Check their reviews on Google, the Better Business Bureau (BBB), and other third-party platforms. Ask for a list of local references for TPO projects they completed several years ago to see how their work has held up over time. A long-standing local presence means they’ll be there to honor their warranties if an issue arises. For a free consultation, call us today at (205) 555-7663.

TPO roofing systems are engineered to last 15-30 years, but they only reach that potential when properly installed. The membrane’s highly reflective surface is a game-changer for properties in Alabama, capable of reducing rooftop temperatures by up to 80°F and cutting cooling costs by as much as 30%. Its formidable puncture resistance and advanced UV stability protect your investment against hail, flying debris, and the relentless sun. Professional TPO roofing installation is a technical craft, and entrusting it to experienced, certified contractors is the only way to guarantee a watertight, long-lasting, and energy-efficient roof.

Related content about tpo roofing companies:

What is TPO Roofing and Why is it the Industry Leader?

When we talk about modern, high-performance roofing solutions for commercial buildings, TPO (Thermoplastic Polyolefin) inevitably dominates the conversation. It is a single-ply roofing membrane that has experienced a meteoric rise in popularity for both commercial and residential properties with flat or low-slope roofs. Its commanding 40% share of the commercial roofing market isn’t an accident; it’s a direct result of its superior engineering, versatility, and proven performance in the field.

But what exactly is TPO, and what specific characteristics make it the standout choice for architects, building owners, and facility managers across the country?

The Anatomy of a TPO Membrane

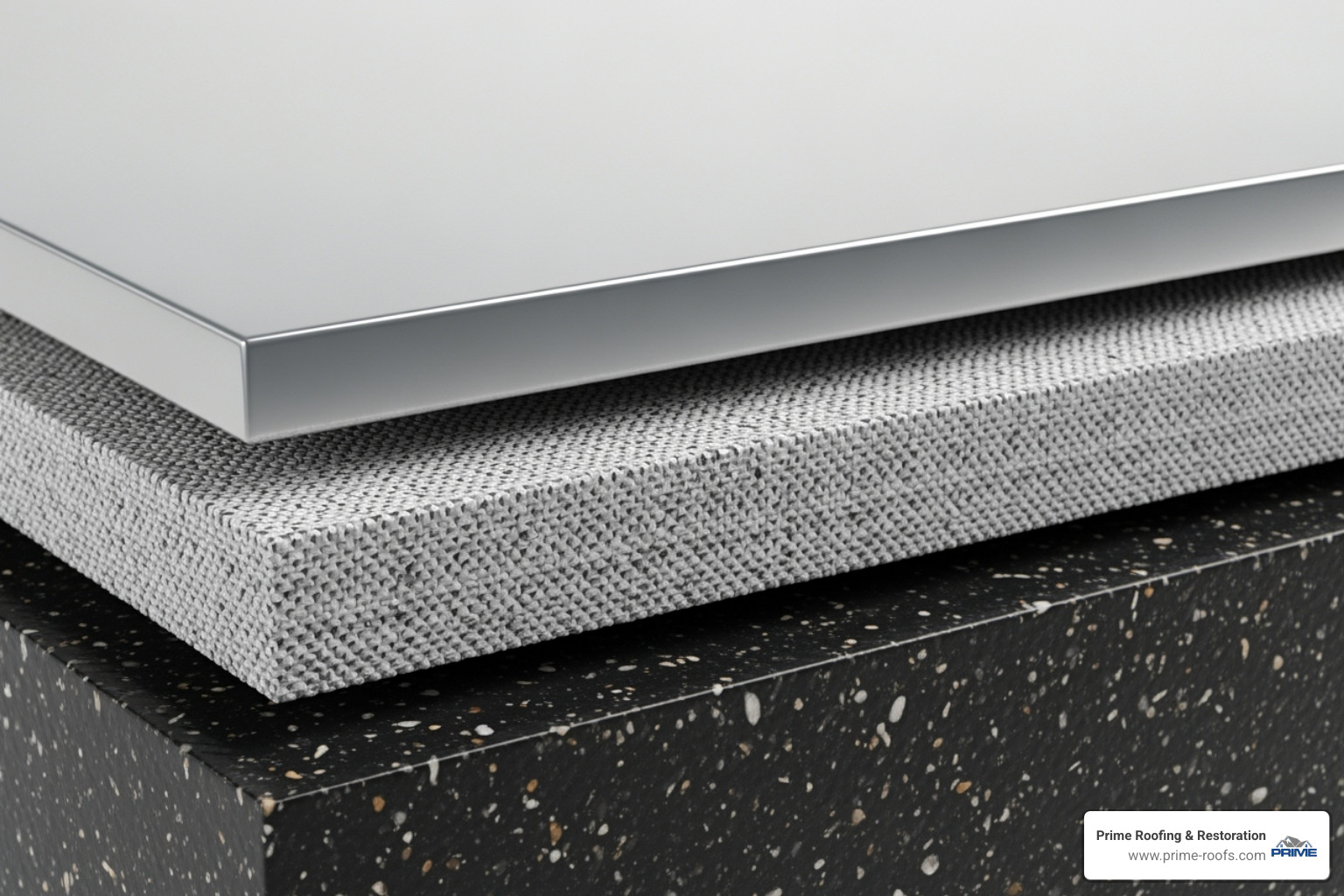

At its core, TPO is a sophisticated blend of polypropylene and ethylene-propylene rubber, combined with a suite of performance-enhancing fillers. This formulation gives the membrane its signature flexibility and durability without the need for plasticizers or chlorine, which can degrade over time. A modern TPO membrane is a marvel of material science, consisting of three co-extruded, integrally bonded layers:

- Top Layer: This is the weather-facing surface, a thick, UV-resistant cap sheet formulated for maximum solar reflectivity and durability. It contains high concentrations of titanium dioxide and other pigments to reflect heat and resist degradation from sun exposure.

- Middle Scrim: The heart of the membrane is a powerful, polyester-reinforced fabric scrim. This woven core provides exceptional dimensional stability, preventing the membrane from shrinking or expanding excessively. More importantly, it delivers incredible strength against tears, punctures, and hail impact, acting as the roof’s primary defense against physical damage.

- Bottom Layer: This base layer is formulated for weldability and contains a precise blend of flame retardants and UV absorbers. It is engineered to create strong, permanent heat-welded seams and to provide additional protection against environmental stressors from below.

This multi-layered construction results in a robust, cohesive, and highly functional roofing material. TPO membranes are available in various thicknesses, typically from 40-mil (0.040 inches) to 80-mil (0.080 inches), allowing for customized solutions based on specific performance requirements, budget, and desired warranty length.

Top 5 Benefits of TPO for Your Property

The advantages of choosing TPO roofing are clear and compelling, contributing to its status as an industry leader. Here are the top five benefits in greater detail:

- Superior Energy Efficiency: TPO’s bright, reflective surface is a key feature. White TPO membranes can reflect over 75% of the sun’s solar energy. This performance earns them an ENERGY STAR rating and a high Solar Reflectance Index (SRI) from the Cool Roof Rating Council (CRRC). By keeping the building’s interior cooler, TPO significantly reduces the load on HVAC systems, leading to substantial energy savings—a critical benefit in Alabama’s long, hot summers.

-

Exceptional Durability and Longevity: With its reinforced scrim and advanced polymer chemistry, TPO offers outstanding resistance to UV radiation, ozone, and chemical exposure. It also stands up remarkably well to punctures, tears, and hail. A properly installed TPO roof that meets or exceeds ASTM D6878 standards can easily last 20-30 years, providing excellent long-term value and minimizing the need for frequent, costly repairs or premature replacement.

-

Cost-Effective Installation and Maintenance: TPO offers a compelling economic advantage. The material itself is often more affordable than alternatives like PVC. Its lightweight nature and availability in large 10- or 12-foot-wide rolls can reduce labor costs and shorten project timelines. Furthermore, its lifetime cost is low. TPO does not require re-coating or re-surfacing, and repairs to seams or cuts are easily and permanently made with simple heat-welding techniques.

-

Flexibility for Various Roof Designs: Buildings are not static; they settle and move with thermal expansion and contraction. TPO membranes are highly flexible and can accommodate this movement without cracking or splitting, a common failure point for more rigid roofing systems. This makes TPO an ideal solution for a wide range of flat and low-slope roof designs, including those with complex shapes, numerous penetrations, and dynamic structural loads.

-

Environmentally Sustainable: For businesses focused on sustainability, TPO is a compelling choice. It is manufactured without chlorine, plasticizers, or other hazardous materials found in some roofing products. Its energy efficiency reduces a building’s carbon footprint. At the end of its service life, TPO is 100% recyclable, diverting tons of material from landfills. Its natural resistance to fungi, bacteria, and algae also helps keep the roof surface cleaner and more reflective over time, contributing to LEED credits for green building projects.

TPO vs. Other Roofing Materials: Why TPO Stands Out

When facing a commercial roof replacement or specifying a system for new construction, the array of options can be overwhelming. While many materials have their place, TPO consistently emerges as a top contender due to its balanced combination of modern performance, long-term durability, and smart economics. To truly appreciate its value, it’s helpful to see how TPO stacks up against other popular commercial roofing materials.

TPO’s Competitive Advantages

TPO offers superior value compared to traditional multi-ply roofing methods and even holds its own against other modern single-ply membranes. Here’s a detailed comparison across the factors that matter most to building owners:

| Feature | TPO Roofing | EPDM (Rubber) Roofing | PVC Roofing | Modified Bitumen (Mod-Bit) | Built-Up Roofing (BUR) |

|---|---|---|---|---|---|

| Cost | Moderate. Excellent value for its performance and lifespan. | Low to Moderate. Often the most economical single-ply option. | Moderate to High. Generally more expensive than TPO. | Moderate. Can be more expensive than TPO, especially multi-ply systems. | Moderate to High. Very labor-intensive installation drives up cost. |

| Lifespan | 15-30+ years. Highly durable and UV resistant. | 20-35+ years. Extremely durable, but seams can be a weak point. | 15-30+ years. Similar to TPO, very durable. | 10-20 years. Shorter lifespan, susceptible to UV degradation. | 15-25 years. Can be shorter with poor maintenance. |

| Seam Strength | Excellent. Hot-air welded seams create a monolithic, watertight bond stronger than the membrane. | Fair to Good. Seams are glued with adhesives, which can degrade over time and require maintenance. | Excellent. Hot-air welded seams are a primary strength, similar to TPO. | Good. Welded or adhesive seams can be susceptible to aging and improper installation. | Good. Asphalt layers bond well but can become brittle and crack. |

| Energy Efficiency | Excellent. Highly reflective (especially white TPO), ENERGY STAR rated. | Poor to Good. Standard black EPDM absorbs heat. White EPDM is available but less common and can be more expensive. | Excellent. Highly reflective, also ENERGY STAR rated. | Moderate. Reflective coatings are available but are less efficient and require reapplication. | Poor. Dark asphalt surface absorbs significant heat. |

| Puncture Resistance | Very Good. The internal scrim provides excellent resistance to punctures and tears. | Good. Flexible but can be more susceptible to punctures than reinforced membranes. | Very Good. Also features an internal scrim for high puncture resistance. | Excellent. Multi-ply systems offer high resistance to foot traffic and impacts. | Excellent. Multiple layers of asphalt and felt create a very tough surface. |

| Environmental Impact | Good. No plasticizers or chlorine, recyclable. | Good. Inert material, but petroleum-based. | Moderate. Contains chlorine and plasticizers, though some can be recycled. | Poor. Petroleum-based, non-recyclable, high VOCs during installation. | Poor. Petroleum-based, non-recyclable, high VOCs and fumes. |

| Installation | Efficient. Lightweight, large rolls. Hot-air welding is fast, safe, and odor-free. | Moderate. Lightweight, but seaming is a slower, more technique-sensitive process. | Efficient. Similar to TPO, though welding can be more temperature-sensitive. | Moderate. Torch-applied options carry significant fire risk and require special insurance. | Complex/Messy. Multiple layers, hot asphalt, strong odors, and heavy equipment. |

What’s impressive about TPO is how it delivers high performance across these categories without major compromises. It decisively outperforms traditional materials like BUR and Mod-Bit in energy efficiency, installation safety, and environmental impact. While EPDM is a durable and often cheaper alternative, TPO’s welded seams provide far superior long-term security. PVC is a very strong competitor, but TPO often wins on cost-effectiveness and its more environmentally friendly, plasticizer-free composition.

Potential Considerations with TPO Roofing

While TPO is an outstanding material, a successful, long-lasting roof depends on a few key factors that building owners must understand.

Skilled installation is non-negotiable. TPO’s greatest strength—its heat-welded seams—is also its biggest vulnerability if not performed by a master technician. Improper welding temperature, speed, or pressure can result in ‘cold welds’ that look sealed but will separate over time, leading to catastrophic leaks. This is precisely why choosing experienced TPO roofing companies with manufacturer-certified technicians is the most important decision you will make for your roof’s long-term success.

Chemical exposure can be a factor. While TPO is resistant to most common atmospheric pollutants, it may not be the ideal choice for roofs with constant exposure to certain harsh industrial chemicals, oils, or greases (e.g., a restaurant with a rooftop grease vent). In these specific scenarios, PVC, which has superior chemical resistance, might be a better option. A professional assessment of your property’s specific environment is always recommended.

Formulations have improved dramatically. Early TPO membranes from the 1990s had some performance issues related to UV degradation. However, today’s TPO is a completely different, fourth-generation product. Through decades of research and development, manufacturers have perfected advanced UV stabilization packages and heat-aging formulas. Reputable contractors only use modern, industry-leading products that have long since resolved these early concerns, backed by decades of proven performance in the field.

The TPO Roofing Lifecycle: Installation, Maintenance, and Replacement

Understanding your TPO roof’s complete journey—from the precision of the initial installation to proactive maintenance and eventual replacement—is the key to maximizing your return on investment. A properly installed TPO roof can deliver decades of reliable, leak-free performance. However, the success of the entire lifecycle begins with getting the installation right the first time, as this directly impacts future maintenance needs, repair costs, and the roof’s ultimate lifespan.

TPO Installation Methods Explained

Experienced tpo roofing companies don’t use a one-size-fits-all approach. They analyze the building’s structure, deck type, geographic location, and wind-uplift requirements to select from several proven installation methods:

-

Mechanically Attached Systems: This is the most common and often most cost-effective method for TPO installation. The membrane is secured to the structural deck using specialized fasteners and plates placed along the seams of the membrane. The overlapping seam is then heat-welded, creating a watertight barrier that completely covers the fasteners. This method provides excellent wind resistance and is ideal for most commercial applications in Alabama.

-

Fully Adhered Installations: In this premium method, the TPO membrane is bonded directly to the underlying substrate (usually insulation or a cover board) with a powerful adhesive. This creates a smooth, seamless, and highly aesthetic appearance. Fully adhered systems offer superior wind uplift resistance, making them perfect for high-rise buildings or structures in high-wind zones. They are also the preferred method for contoured roofs or those with unusual shapes.

-

Induction Welded Systems: This cutting-edge technique combines the benefits of the other two methods. Special plates are anchored to the roof deck, and the TPO membrane is laid over them. A specialized induction welding tool is then used to heat the plates through the membrane, welding the underside of the TPO directly to the plate. This provides the wind uplift performance of a fully adhered system without the use of adhesives and their associated temperature limitations during installation.

Regardless of the method, every professional installation begins with meticulous site and insulation preparation. The roof deck must be clean, dry, and structurally sound. The critical heat-welded seaming process requires certified technicians to perform daily test welds, calibrating their equipment to the specific weather conditions to ensure every inch of the seam is stronger than the membrane itself.

Proactive Maintenance: Signs Your TPO Roof Needs Professional Attention

Early detection of minor issues is the best way to prevent them from becoming major, costly problems. A proactive maintenance plan is essential. We recommend semi-annual inspections, typically in the spring and fall. If you notice any of the following warning signs, call a professional immediately:

-

Cracks, Splits, or Crazing in the Membrane: These can be signs of stress, age, or physical damage. Even small cracks can allow water to penetrate the system and must be repaired promptly.

-

Seam Separation or Failure: This is a critical issue where welded seams begin to pull apart, creating a direct path for water infiltration. It is often a sign of improper initial installation and requires immediate expert attention.

-

Blistering, Bubbles, or Peeling: Bubbles or areas where the membrane has detached from the substrate indicate adhesion failure. This is often caused by moisture trapped within the roofing system and can spread if not addressed.

-

Ponding Water: Any water that remains on your roof for more than 48 hours after rainfall is a sign of a drainage problem. Ponding water accelerates membrane aging, adds significant weight to the structure, and can void your warranty.

-

Weathering, Punctures, or Damage: Look for signs of excessive surface chalking, thinning of the membrane, or any physical damage from foot traffic, falling branches, or storm debris. These areas must be professionally patched to prevent leaks.

When our team finds these issues, we perform a thorough assessment, including an infrared scan if necessary, to determine the extent of moisture saturation in the insulation. If saturation is below 25%, a cost-effective restoration coating may be a viable option to extend the roof’s life. If it’s higher, a full replacement is typically the only responsible recommendation. For urgent issues like storm damage or active leaks, we provide 24/7 emergency services to protect your property. Call us anytime at (205) 555-7663.

How to Choose the Best TPO Roofing Companies for Your Project

Choosing the right TPO roofing companies is unequivocally as important as choosing the TPO material itself. A high-quality, 80-mil TPO membrane from a top manufacturer will fail prematurely if installed by an inexperienced or careless contractor. After years in the Alabama roofing industry, I’ve seen the unfortunate aftermath of poor workmanship: failed seams, chronic leaks, and building owners facing a complete re-roofing project just a few years after their initial investment. A great TPO roof is a system, and the contractor is the most critical component.

Key Factors for Vetting TPO Roofing Companies

When evaluating potential contractors for your commercial roofing project, use this checklist of non-negotiable qualifications to separate the true professionals from the rest:

-

Proper Licensing and Insurance: This is the absolute baseline. Verify that the contractor holds all necessary state and local licenses. In Alabama, you can verify a roofer’s license through the Alabama Home Builders Licensure Board. Crucially, ask for a certificate of insurance and verify that it includes both general liability (at least $2 million in coverage is standard for commercial work) and worker’s compensation. This protects you from any liability in case of accidents on your property.

-

Specialization and Deep Expertise in TPO Systems: A company that “does it all” may not be an expert in anything. The best TPO roofing companies have dedicated crews that specialize in single-ply systems. Ask them what percentage of their commercial work involves TPO. They should be able to speak fluently about different manufacturers, installation techniques, and how to handle complex details like curbs, pipes, and drains.

-

Manufacturer Certifications: This is a powerful indicator of quality. Certifications from leading manufacturers like GAF, Carlisle, Firestone, or Johns Manville mean the contractor has been professionally trained and vetted. These certifications are not easy to obtain; they require proving financial stability, having a track record of quality installations, and passing rigorous exams. A certified contractor can also offer you the best warranties available, including comprehensive NDL (No Dollar Limit) warranties.

-

Transparent Pricing and Detailed Proposals: A professional proposal is not a one-page estimate. It should be a detailed, itemized document that clearly outlines the scope of work, the specific materials to be used (including manufacturer and thickness), the installation method, tear-off and disposal procedures, and the warranty details. Beware of vague proposals or contractors who pressure you for a quick decision.

-

Strong Client Testimonials and References: Look beyond the curated reviews on their website. Check third-party sites like Google and the BBB. Most importantly, ask for references for recent TPO projects similar in scope to yours. A confident contractor will be happy to provide them.

-

Local Knowledge and Business Longevity: An established local contractor understands Alabama’s specific building codes, weather patterns, and permitting processes. The roofing industry has a high turnover rate; choosing a company that has been in business for many years ensures they have a stable operation and will be around to honor their workmanship warranty.

Understanding TPO Warranties and Quality Assurance

A strong warranty is a reflection of both the manufacturer’s and the contractor’s confidence in the final product. It’s vital to understand the two main types. Manufacturer warranties cover defects in the TPO membrane itself, with terms up to 35 years. Workmanship warranties are provided by the contractor and cover defects in the installation. The best warranties are full coverage or NDL (No Dollar Limit) warranties, which are often available only through certified installers and cover both labor and materials for the entire term without proration. Professional contractors also have internal quality assurance programs, with dedicated project managers and site superintendents conducting regular inspections to ensure every step of the installation meets the highest standards.

What to Expect for TPO Roofing Costs

TPO roofing installation for a commercial project typically ranges from $7 to $14 per square foot. This is a wide range because several key factors influence the final price:

-

Membrane Thickness: A standard 45-mil membrane is a cost-effective choice for some applications. However, upgrading to a thicker 60-mil or 80-mil membrane provides significantly better durability, puncture resistance, and longer warranty options for a marginal increase in upfront cost.

-

Installation Method: Mechanically attached systems are often the most economical. Fully adhered or induction welded systems cost more due to additional labor and material requirements but provide superior performance and aesthetics.

-

Roof Complexity and Condition: A simple, wide-open roof is less expensive than one with numerous HVAC units, skylights, pipes, and multiple levels. The condition of the existing roof is also a major factor. A complete tear-off of an old roof system will add significantly to the cost compared to a re-cover application (if permissible by code).

-

Insulation and Substrate: The type and thickness of the insulation used beneath the TPO membrane will impact the price. Upgrading insulation can increase costs but also dramatically improve your building’s R-value and energy efficiency.

-

Location and Labor: Material delivery costs and local labor rates vary by region and can influence the final quote.

Frequently Asked Questions about TPO Roofing

Over our many years serving Alabama property owners, we’ve found that clients consistently ask the same insightful questions about TPO roofing. To help you make an informed decision, we’ve compiled detailed answers to the most common inquiries.

How long does a TPO roof last?

A professionally installed and properly maintained TPO roof has a service life of 15 to 30 years. The final lifespan is influenced by several key factors. Membrane thickness is paramount; a 60-mil or 80-mil membrane will significantly outlast a standard 45-mil sheet. Local climate conditions, such as Alabama’s intense UV exposure and potential for severe weather, also play a role, making the quality of the UV stabilization package in the membrane critical. Most importantly, the quality of the initial installation by experienced tpo roofing companies is the number one predictor of longevity. Finally, regular maintenance, including semi-annual inspections and keeping drains and scuppers clear of debris, is crucial to maximizing the roof’s service life and preventing minor issues from escalating.

Is TPO roofing a good choice for residential homes?

Absolutely. While TPO is dominant in the commercial sector, it is an outstanding choice for residential properties that have flat or low-slope roof sections. This is common for garages, porch and patio covers, room additions, and modern home architectural designs. Homeowners can reap the same benefits as commercial property owners, especially the significant energy efficiency. A reflective TPO roof can reduce cooling costs by up to 30%—a huge advantage in the Alabama heat. Its durability, flexibility against structural settling, and long 20-30 year lifespan provide excellent long-term value and peace of mind compared to traditional residential flat-roofing materials like modified bitumen.

How much does TPO roofing cost?

The installed cost of TPO roofing typically ranges from $7 to $14 per square foot. The final price on a proposal will depend on a detailed assessment of several factors:

- Membrane Thickness: Thicker membranes like 60-mil or 80-mil cost more upfront but offer superior durability and extended warranty coverage, often making them a better long-term value.

- Installation Method: Mechanically attached systems are generally the most economical. Fully adhered or induction welded systems require more labor and materials, increasing the cost, but offer enhanced wind resistance and a smoother appearance.

- Roof Complexity: A simple, square roof is less expensive than a complex one with numerous penetrations (pipes, vents, skylights), parapet walls, or unusual shapes that require more detailed labor.

- Underlying Structure: The cost will be affected by the need for new insulation, a cover board, or a complete tear-off of the existing roof system, which is labor-intensive.

- Other Factors: Local labor rates, accessibility of the roof, geographic location, and warranty choice will also impact the final price. A professional contractor will provide a detailed estimate breaking down all costs.

What is the difference between TPO and EPDM roofing?

This is a very common question. Both are excellent single-ply membranes, but they have key differences. TPO seams are heat-welded, creating a single, monolithic sheet that is incredibly strong and durable. TPO is also naturally reflective (in white and light colors), making it highly energy-efficient. EPDM (rubber roofing) seams are typically sealed with adhesives and tapes. While effective, these seams can be a point of failure over time as the adhesives degrade. Standard EPDM is black and absorbs heat, making it less energy-efficient, although reflective white versions are available. EPDM is extremely durable and flexible, often with a slightly longer potential lifespan, but TPO’s seam strength and built-in energy efficiency make it the preferred choice for many modern applications.

Can you install TPO roofing in any weather?

No, weather conditions are a critical factor for a quality TPO installation. Heat-welding requires the ambient and membrane temperature to be within a specific range (typically above 40°F) to achieve a proper molecular bond. Attempting to weld in cold weather can result in weak seams that fail prematurely. Similarly, if using a fully adhered system, the adhesives have strict temperature and humidity requirements for proper curing. Any moisture, such as rain or even heavy dew, can compromise the installation. A professional TPO contractor will closely monitor weather conditions and will not proceed if they are not optimal for a successful, long-lasting installation.

Your Partner for TPO Roofing Success

When you invest in a TPO roofing system, you’re choosing a solution engineered for exceptional durability, significant energy savings, and outstanding long-term value. But as we’ve emphasized, even the most advanced TPO membrane can fail if it’s not installed with precision and expertise. Your choice of contractor matters just as much, if not more, than your choice of material. The success of your TPO roof for the next 20 to 30 years hinges on two critical factors: expert installation and quality materials.

Poor welding techniques, improper fastener patterns, or shortcuts during substrate preparation can turn a multi-decade investment into a costly, recurring headache of leaks and repairs. Don’t let that happen to your property.

For property owners across Alabama, Prime Roofing & Restoration is the trusted partner that brings certified expertise to every TPO roofing project. Our dedicated commercial roofing crews understand the unique challenges of Alabama’s climate—from intense summer sun and high humidity to the threat of severe storms—and we know precisely how to install TPO membranes that are built to withstand these conditions.

What sets us apart from other tpo roofing companies? We are committed to being your long-term roofing partners, not just a one-time contractor. Our licensed, insured professionals undergo continuous training on the latest TPO installation techniques and safety protocols. We use only industry-leading materials from trusted manufacturers, ensuring your roof is not only built to last but that its warranty coverage remains fully intact.

We are proud to be a local Alabama business, and we stand behind our work with a robust workmanship warranty. Our reputation is built on quality, transparency, and reliability. We invite you to contact us for a professional consultation and experience the difference for yourself.

Prime Roofing & Restoration

Address: 123 Main Street, Alabaster, AL 35007

Phone: (205) 555-7663

We also understand that roofing emergencies don’t wait for business hours. That’s why we provide 24/7 emergency support for our clients throughout Alabaster, AL, Birmingham, and the surrounding areas. Whether you’re dealing with storm damage or a sudden, active leak, our rapid response team is ready to protect your asset.

Your property deserves the ultimate protection from professionals who stand behind their work. Don’t trust your investment to just anyone. Protect your investment with the best in the business—Contact Us today for a free, no-obligation estimate and comprehensive roof assessment.