Understanding Built-Up Roof Systems: A Century of Proven Protection

A built-up roof replacement is a significant but necessary investment for any commercial property owner when these time-tested systems reach the end of their functional lifespan. With a typical service life of 15 to 40 years, a built-up roof (BUR) can be severely compromised by decades of wear, UV degradation, and the relentless forces of Alabama’s severe weather. For discerning property owners, understanding the precise moment to replace versus repair is the key to safeguarding the building’s structural integrity and operational continuity. The experts at Prime Roofing & Restoration are here to provide the clarity and guidance you need. A built-up roof, often referred to as a “tar and gravel” roof, is a robust, multi-layered system composed of alternating layers of bitumen (asphalt) and reinforcing fabrics (ply sheets). This construction method creates a thick, seamless, and monolithic waterproof membrane, making it one of the most durable and proven roofing technologies ever developed.

Originating in the 1840s, BUR technology has protected buildings for over a century, evolving from coal tar pitch and organic felts to modern asphalt and high-performance fiberglass mats. Its longevity in the market is a testament to its core strength: redundancy. Unlike single-ply systems, a puncture or split in the top layer of a BUR does not immediately result in a leak, as multiple underlying layers provide backup protection. This inherent toughness is why it remains a top choice for industrial, commercial, and institutional buildings that demand maximum durability.

Quick Answer: When to Replace Your Built-Up Roof

- Advanced Age and Repair Frequency: If your system is over 20 years old and you find yourself calling for repairs annually, it’s a clear sign that the roof is in systemic decline and a replacement is the most cost-effective long-term solution.

- Widespread Surface Degradation: Look for extensive blistering, deep cracks resembling alligator skin (“alligatoring”), or exposed felt layers. These indicate the asphalt has lost its protective oils and waterproofing capability.

- Chronic Leaks and Interior Damage: Persistent leaks that reappear despite repairs, or new leaks emerging in different locations, signal widespread membrane failure. This often manifests as water stains on ceilings, peeling paint, or the growth of mold.

- Exposed Reinforcing Felts: When the top layer of gravel or cap sheet erodes, the underlying fabric layers are exposed to direct sunlight, which rapidly accelerates their deterioration and leads to splits and fractures.

- Significant Drainage Failures: Large areas of ponding water that remain on the roof for more than 48 hours after rain indicate structural sagging or blocked drains. The immense weight of this water can cause structural damage and will rapidly degrade the roofing membrane.

For property owners across Central Alabama, from Alabaster to Hoover, recognizing these critical signs can be the difference between a planned, budgeted replacement and a catastrophic emergency failure that costs thousands more in interior damage and business disruption. My name is Bill Spencer, owner of Prime Roofing & Restoration. With years of hands-on experience specifying and installing BUR systems along the Gulf Coast, I’ve seen firsthand how a correctly timed replacement protects not just the building, but the owner’s budget and peace of mind. If you’re in the Alabaster area and need an honest, expert assessment, our team of roofers near me in Alabaster, AL is ready to assist. Give us a call at (205) 555-0199 to schedule a no-obligation inspection.

5 Critical Signs Your Built-Up Roof Needs Replacement

Your built-up roof was engineered for exceptional longevity, often providing 15 to 40 years of steadfast protection. However, the demanding Alabama climate—characterized by intense summer heat, high humidity, torrential downpours, and the threat of hail and high winds—can significantly accelerate the aging process. When isolated problems evolve into widespread, recurring issues, a complete built-up roof replacement transitions from a future consideration to a present necessity. It is often the most prudent financial decision, preventing the cascading costs of structural repairs, damaged inventory, and operational downtime. Ignoring these five critical warning signs is a gamble that will inevitably lead to more extensive and expensive consequences.

Let’s delve into the five definitive indicators that your BUR system has reached the end of its service life and is due for a full replacement.

1. Widespread Blistering and “Alligatoring”

Blistering manifests as raised bubbles or pockets on the roof’s surface. These are formed when air or moisture becomes trapped between the layers of felt or between the membrane and the roof deck. As the sun heats the roof, the trapped gas or water vapor expands, creating pressure that stretches the asphalt and forms a blister. While a few isolated, small blisters might be manageable with targeted repairs, widespread or large blisters (over a foot in diameter) indicate a systemic failure. These blisters are weak points that can easily rupture under foot traffic or stress, creating an immediate entry point for water.

Alligatoring is a distinct pattern of interconnected cracking that closely resembles the hide of an alligator. This phenomenon is a tell-tale sign of an aged roof. Over years of exposure to UV radiation, the volatile oils in the asphalt that give it flexibility and waterproofing properties evaporate. The asphalt becomes brittle and shrinks, causing the surface to crack. Minor surface crazing may be treatable with a coating, but deep, extensive alligatoring that exposes the underlying felt means the membrane has lost its ability to expand and contract with temperature changes. It has become fragile and can no longer provide reliable waterproofing. These two issues, especially when appearing together, signal that the asphalt membrane has aged beyond the point of effective repair.

2. Persistent Leaks and Interior Water Damage

While a single, isolated leak from a piece of damaged flashing might be a simple fix, multiple leaks occurring simultaneously or a chronic leak that reappears after repairs are clear indicators of system-wide failure. On a flat roof, water can travel a significant distance from its point of entry before showing up as a stain on a ceiling, making leak detection notoriously difficult. If you are chasing leaks around your building, the problem is likely the entire roof membrane, not a single defect.

Persistent water intrusion leads to a devastating cascade of problems. The most obvious are unsightly water stains on ceiling tiles, bubbling or peeling paint, and the distinct, musty odor of mold or mildew. Beyond the cosmetic issues, waterlogged insulation loses its thermal resistance (R-value), causing your energy bills to spike. This perpetually damp environment becomes a perfect breeding ground for harmful mold and bacteria, posing a health risk to building occupants. The most dangerous, unseen damage occurs to the roof deck and structural supports. Water can cause wood decking to rot, steel decking to rust and corrode, and concrete to spall. A professional inspection, as part of our comprehensive commercial roofing services, can determine if you’re facing isolated issues or a complete system failure that threatens your building’s structural integrity.

3. Significant Membrane Deterioration and Splitting

The top layer of a traditional BUR system is an aggregate surface of gravel or slag. This layer is not just for looks; it is a crucial component that shields the underlying asphalt layers from damaging UV radiation and provides a high degree of fire resistance. When this protective gravel surface erodes due to wind scouring, foot traffic, or water flow, the asphalt-saturated felt layers are left exposed. Direct UV exposure rapidly accelerates the aging process, making the membrane brittle and prone to damage.

This leads to membrane splitting—a severe warning sign. You will see exposed, weathered felt layers and long, linear cracks or splits in the membrane. As the membrane becomes brittle, it loses its ability to flex with the building’s natural expansion and contraction. Stress concentrates at points like panel joints in the roof deck, causing the membrane to split open. These splits create direct, wide paths for water to pour into your building. This level of advanced deterioration is one of the classic 5 Signs You Need Roof Replacement and requires immediate professional intervention to prevent catastrophic water damage.

4. Structural Issues and Ponding Water

A properly designed low-slope roof is not perfectly flat; it has a slight pitch to direct water toward drains, scuppers, or gutters. According to the National Roofing Contractors Association (NRCA), a roof should drain completely within 48 hours of rainfall. Ponding water that lingers for days is a serious red flag. It indicates a drainage problem, which could be caused by clogged drains or, more seriously, by structural deformation in the roof deck.

The weight of standing water is immense—a single gallon weighs over 8.3 pounds. An area of ponding water just one inch deep over a 10×10 foot area adds over 520 pounds of stress to your roof structure. This static load can cause the roof deck to sag or deflect, which in turn creates a deeper pond, allowing more water to collect in a vicious cycle that can lead to structural collapse. Furthermore, standing water accelerates the deterioration of the roofing membrane, promoting algae growth, breaking down asphalt, and finding its way into any tiny crack or seam. If you notice persistent areas of ponding water or can see visible sagging in the roofline, the problems likely extend far beyond the membrane. A built-up roof replacement is necessary to correct both the surface and the underlying structural issues.

5. Advanced Age and High Maintenance Costs

Every roofing system has a finite lifespan. Even a well-maintained BUR system that exceeds 20-25 years of age is living on borrowed time. As the system ages, the frequency and cost of repairs will inevitably increase. Continuing to patch an old, brittle roof that is well past its warranty period is a financially unsustainable strategy. This approach, often called a “chase and patch” cycle, is a losing battle against time and the elements.

A smart building owner employs life-cycle cost analysis. When the annual cost of maintenance and repairs begins to approach a significant fraction of the cost of a new system, replacement becomes the more economical and logical option. Investing in a new roof provides a new warranty, predictable (and minimal) maintenance costs for years to come, and improved energy efficiency. While proactive maintenance is crucial for extending a roof’s life, there comes a point where the system is simply worn out. Recognizing this endpoint saves you money in the long run and prevents the immense stress and disruption of an unexpected, large-scale failure.

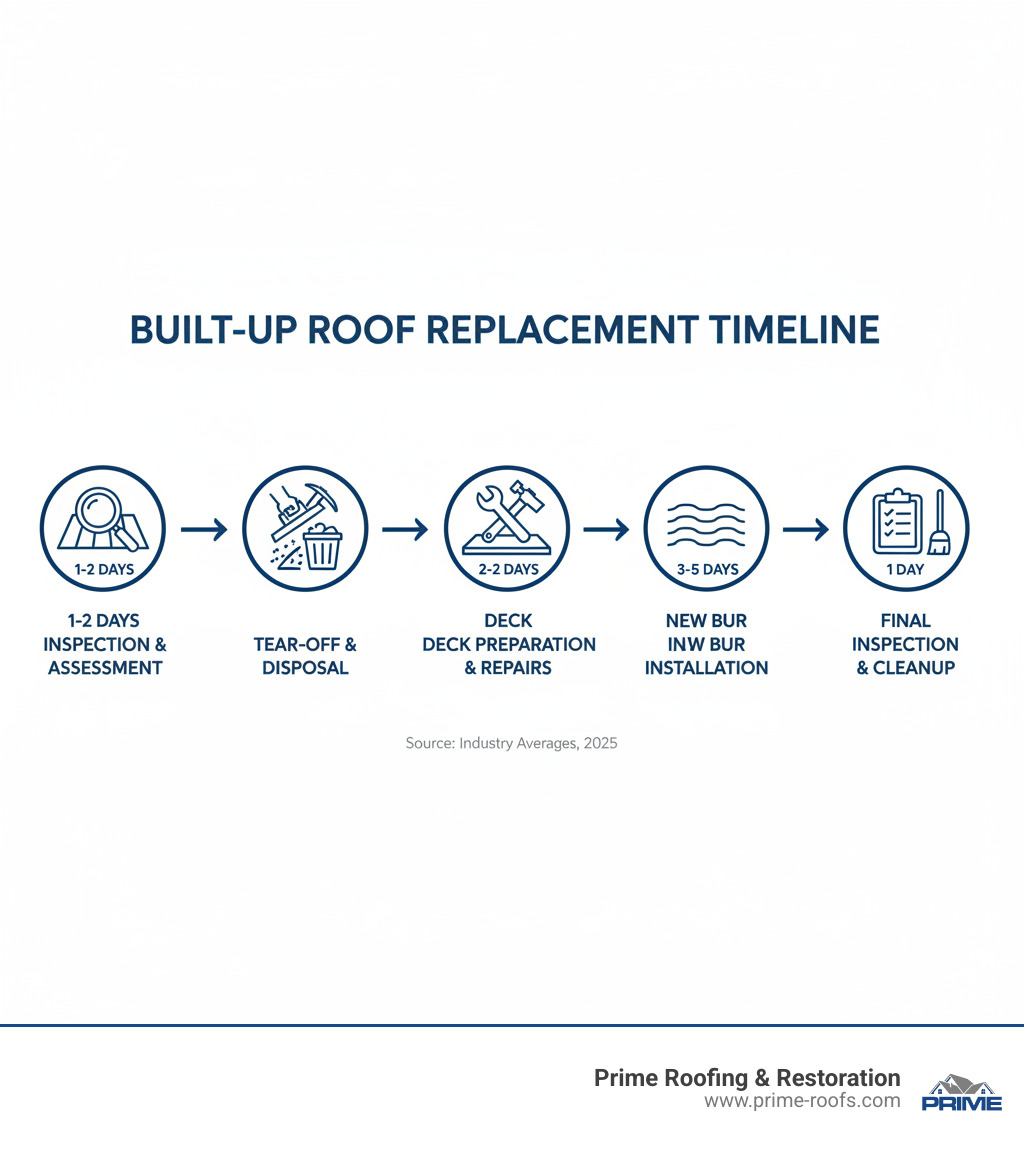

The Complete Built-Up Roof Replacement Process

A built-up roof replacement is a highly technical and demanding construction project that should only be undertaken by experienced, professional roofing contractors. It involves specialized equipment for handling hot asphalt, strict safety protocols to protect workers and the property, and a deep understanding of material science to ensure the new system performs for decades. At Prime Roofing & Restoration, we follow a meticulous, multi-stage process to guarantee that your new roof is not just installed, but engineered for maximum durability and longevity.

Step 1: Thorough Inspection, Core Sampling, and Project Planning

Every successful replacement project begins long before the first tool is picked up. The initial phase is a comprehensive inspection and analysis. Our commercial roofing services team conducts a detailed assessment that goes far beyond a simple visual check. We perform core sampling, which involves cutting small, cylindrical sections out of the existing roof. This allows us to physically examine a cross-section of the system to determine the exact number of existing layers, the type and condition of the insulation, and the composition of the roof deck. We also utilize non-destructive methods like infrared thermography to detect trapped moisture invisible to the naked eye. A complete drainage evaluation is performed to identify issues with slope, drains, and scuppers. All roof penetrations—such as HVAC units, vents, pipes, and skylights—are meticulously assessed, as these are common points of failure. This critical planning phase allows us to define the precise scope of work, provide a highly accurate estimate, and engineer a project plan that minimizes surprises and ensures a smooth execution.

Step 2: Safe and Systematic Removal of the Old System (Tear-Off)

The tear-off phase is the most physically demanding and logistically complex part of the project. A multi-layer BUR is incredibly heavy; a typical four-ply tar and gravel system can weigh between 600 and 800 pounds per 100 square feet (a “square” in roofing terms). This means a relatively small 5,000-square-foot roof could have over 20 tons of material that needs to be removed. Our crews work systematically, using specialized tools like roof cutters and spud bars to remove all layers of gravel, asphalt, felt, and insulation down to the structural deck. We adhere to strict OSHA safety standards for fall protection and worksite safety. We manage debris disposal with military precision, using chutes and designated ground-level dumpsters to maintain a clean and safe environment, minimizing disruption to your business operations. This process follows best practices outlined by government and industry authorities, such as those from the GSA on replacing asphalt roofs.

Step 3: Meticulous Deck Preparation and Repair

Once the old system is completely removed, the bare structural deck is exposed. This is a crucial opportunity to inspect for and correct any hidden damage. Our project manager conducts a meticulous deck inspection, looking for issues like rotted or delaminated wood sheathing, corroded or bent steel panels, or cracked and spalled concrete. Any compromised sections are repaired or replaced to create a solid, uniform, and structurally sound foundation for the new roof. This is non-negotiable; installing a new roof over a damaged deck is a recipe for premature failure. This stage is also the ideal time to upgrade the roof’s thermal performance by adding or replacing insulation to meet or exceed modern energy codes. Finally, the entire substrate is cleaned of all dust and debris. Ensuring a clean, dry, and smooth substrate is absolutely critical for the proper adhesion and long-term performance of the new BUR system.

Step 4: Installing the New Multi-Ply BUR System

This is where true roofing craftsmanship is on display. Our certified roofers build the new BUR system layer by layer, adhering to precise manufacturer specifications. The process typically begins with the mechanical attachment or adhesion of a base sheet to the prepared deck or insulation. We then apply alternating layers of reinforcing felt (ply sheets) and hot-applied bitumen. The bitumen, heated in a kettle to around 450-500°F, is applied via a “hot mop” to fully saturate and bond each ply sheet. The number of plies—typically two to four—is specified based on the building’s needs and budget, with more plies providing greater strength and redundancy. While hot-mopping is the traditional and time-proven method, advances in manufacturing have also introduced high-performance cold-applied adhesives as an effective, low-odor alternative. The final step is the application of a surface layer. This can be the traditional layer of embedded gravel or slag for UV and fire protection, or a mineral-surfaced cap sheet. Increasingly, clients are choosing a reflective cap sheet or a specialized coating to create a “cool roof” that improves energy efficiency by reflecting solar radiation.

BUR vs. Other Flat Roofs: A Comparative Look

Choosing the right roofing material is a critical decision that will impact your property’s maintenance budget, energy costs, and resilience for decades. While the built-up roof (BUR) is a classic choice with over a century of proven performance, modern roofing technology offers several other excellent options. As part of our comprehensive commercial roofing services, we help clients navigate these choices to select the optimal system for their specific building, budget, and performance priorities.

Built-Up Roof (BUR) System

A Built-Up Roof (BUR) system is the heavyweight champion of flat roofing. Renowned for its exceptional durability, a properly installed BUR can last 20-40 years. Its primary strength lies in its redundant, multi-layer construction, which provides unmatched waterproofing and the highest puncture resistance against hail, dropped tools, and heavy foot traffic. The gravel or slag surfacing adds Class A fire resistance and excellent protection from UV rays. However, BUR systems have their drawbacks. They are extremely heavy, requiring a robust roof deck to support their weight. The installation process is also labor-intensive, weather-sensitive, and the hot asphalt application produces strong odors and fumes (VOCs) that can be disruptive.

Modified Bitumen (Mod-Bit)

Modified Bitumen is a direct evolution of BUR, often described as a factory-assembled, higher-tech version. It incorporates polymers into the asphalt to enhance its performance characteristics. There are two main types: SBS (Styrene-Butadiene-Styrene), which adds rubber-like flexibility and is excellent for colder climates, and APP (Atactic Polypropylene), which creates a durable, plastic-like surface with high-temperature tolerance. Mod-Bit comes in rolls, making installation faster and less labor-intensive than BUR. It offers very good puncture resistance with fewer layers, making it lighter than a traditional BUR. The main trade-offs are fewer redundant layers and the critical importance of seam integrity, as the seams between rolls are the most vulnerable points. Application methods include torching, hot-mopping, or using cold-applied adhesives, with torch-down methods carrying inherent fire risks during installation.

Single-Ply Membranes (TPO & EPDM)

Single-ply membranes are modern, lightweight, and highly popular roofing systems. The two dominant types are TPO and EPDM.

- TPO (Thermoplastic Olefin) is a heat-weldable membrane, typically white, that is highly reflective. This makes it an excellent choice for energy efficiency, as it reflects solar heat and can significantly lower cooling costs in hot climates like Alabama’s. The seams are welded with hot air to form a monolithic, waterproof bond that is exceptionally strong.

- EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber membrane, typically black, with a proven track record of over 50 years. It is extremely durable, flexible in cold temperatures, and resistant to hail and UV degradation. Seams are typically sealed with specialized adhesive tapes.

The primary advantages of both TPO and EPDM are fast, clean installation and their light weight. The main downsides are that, as single-ply systems, they are more susceptible to punctures than multi-ply systems and have no redundancy. The long-term performance is entirely dependent on the quality of the seam work.

PVC (Polyvinyl Chloride)

Another popular single-ply option, PVC roofing has been used for decades and is known for its exceptional resistance to chemicals, grease, and fire. Like TPO, PVC membranes have heat-welded seams that create a strong, watertight bond. PVC is a great choice for restaurants or manufacturing facilities where rooftop grease vents or chemical exhaust could damage other membrane types. It is durable and reflective, but often comes at a higher price point than TPO or EPDM and can be less flexible in very cold temperatures.

Comparing Your Options

| System Type | Average Lifespan (Years) | Puncture Resistance | Installation Complexity | Average Cost (per sq ft) | Energy Efficiency | Key Advantage |

|---|---|---|---|---|---|---|

| Built-Up Roof (BUR) | 20-40 | Excellent | High | $15 – $40 | Moderate | Maximum Durability & Redundancy |

| Modified Bitumen | 15-25 | Good to Excellent | Medium | $10 – $25 | Moderate | Balanced Performance & Durability |

| TPO Single-Ply | 15-30 | Moderate | Low-Medium | $8 – $20 | Excellent (White) | Energy Savings & Seam Strength |

| EPDM Single-Ply | 20-30+ | Good | Low-Medium | $8 – $20 | Low (Black) | Proven Durability & Flexibility |

| PVC Single-Ply | 20-30+ | Good | Low-Medium | $12 – $25 | Excellent (White) | Chemical & Fire Resistance |

Note: Costs are industry approximations for materials and installation and can vary significantly based on location, contractor, building complexity, and specific project requirements.

The best choice depends entirely on your priorities. For a warehouse demanding maximum durability and puncture resistance, BUR remains a top contender. For a retail building where energy efficiency and speed of installation are key, TPO is often the preferred choice. For a restaurant, PVC’s grease resistance is a major benefit. Our experts can help you perform a cost-benefit analysis for your specific property.

Understanding Costs and Choosing Your Contractor

A built-up roof replacement is a significant capital expenditure, with typical costs ranging from $15 to $40 per square foot. This wide range reflects the fact that no two roofing projects are identical. Numerous variables influence the final price, and understanding these cost drivers is essential for accurately evaluating contractor bids and planning your budget. A low-ball bid that overlooks key factors will almost certainly lead to costly change orders or a subpar installation.

Key Factors Influencing Your Built-up Roof Replacement Cost

- Roof Size and Complexity: While a larger roof naturally costs more in total, the price per square foot often decreases on very large, simple roofs due to economies of scale. Conversely, a smaller roof with high complexity—meaning numerous penetrations like vents, drains, skylights, HVAC units, and parapet walls—will have a higher per-square-foot cost due to the intensive labor required for detailed flashing work.

- Building Height and Accessibility: A single-story warehouse with easy access for cranes and material loading will be less expensive to re-roof than a multi-story building in a tight urban environment. Height and difficult access increase costs for labor, safety equipment (scaffolding, harnesses), and material handling (requiring larger cranes).

- Number of Existing Roof Layers: Building codes often limit the number of roof systems that can be installed on top of one another. A complete tear-off is almost always required for a BUR replacement. Removing one old roof is standard, but if a previous contractor improperly installed a roof-over, removing two or more systems significantly increases labor and disposal costs. A four-layer BUR can weigh up to six tons on a small 400 sq ft roof, and disposal fees are calculated by weight.

- Condition of the Roof Deck and Structure: This is the biggest potential variable. Any rot, corrosion, or structural damage discovered after the tear-off must be repaired before the new roof can be installed. Repairing rotted wood sheathing or replacing corroded steel decking is an additional cost but is absolutely essential for a lasting result and is required by code.

- Insulation Type and Thickness (R-Value): Modern energy codes mandate specific minimum insulation levels (R-value) to improve energy efficiency. A replacement is the perfect time to upgrade. The type of insulation (e.g., Polyisocyanurate, EPS, XPS) and the required thickness to meet code will impact the total project cost but will deliver long-term savings on your heating and cooling bills.

- Surface Material and Warranty Level: Your choice of surfacing—traditional gravel, a standard mineral cap sheet, or a premium reflective “cool roof” cap sheet—affects both price and performance. Likewise, choosing an enhanced manufacturer’s warranty (e.g., a 20- or 30-year NDL – No Dollar Limit warranty) often requires higher-grade materials and more stringent installation standards, which adds to the upfront cost.

Our detailed Roof Replacement Cost Guide offers more in-depth information to help you budget effectively for your project.

How to Choose a Qualified Contractor for Your Built-up Roof Replacement

Selecting the right commercial roofing contractor is the single most important decision you will make in this process. The highest quality materials will fail if installed improperly. A professional contractor is your partner in protecting your investment. Here’s what to look for:

- Proven Local Experience: A contractor with deep roots in the Alabaster, AL area will have intimate knowledge of local building codes, permitting processes, and the specific weather challenges of our region. They will have a local reputation to uphold.

- Proper Insurance and Licensing: Do not take their word for it. Ask to see current certificates for both General Liability Insurance (at least $2 million recommended for commercial work) and Workers’ Compensation. Verify that they are a Licensed Roof Contractor in the state of Alabama. This protects you from liability in case of an accident.

- Manufacturer Certifications: Top-tier manufacturers (like GAF, Johns Manville, Carlisle, Firestone) grant certifications to contractors who have been trained and tested on their specific systems. This certification is often required for the best warranties and demonstrates a commitment to quality.

- Detailed, Transparent Written Estimates: A professional bid is not a one-line price. It should be a detailed proposal that breaks down all costs for labor, specific materials, permits, tear-off, debris removal, and deck repairs. Be wary of vague estimates or bids that are significantly lower than others; they have likely cut corners.

- Strong Workmanship Warranties: A manufacturer’s warranty covers defective materials, but a contractor’s workmanship warranty covers installation errors. A reputable contractor will stand behind their work with a clear, long-term warranty. Ask for the terms in writing.

- References and Past Projects: Ask for a list of recent, relevant commercial projects. Take the time to call their references and, if possible, look at their past work. This is the best indicator of the quality you can expect.

Our comprehensive guide on CHOOSING A ROOFER provides more essential tips. Remember, the lowest bid is rarely the best value. Your focus should be on finding a contractor with the expertise, credentials, and proven track record to protect your valuable commercial asset.

Frequently Asked Questions about Built-Up Roofs

Property owners and facility managers considering a built-up roof replacement often have important questions about the process, performance, and value of this roofing system. Here are clear, direct answers to the most common inquiries we receive.

How long does a new built-up roof last?

A professionally installed built-up roof has an impressive lifespan, typically lasting 20 to 30 years. Some exceptionally well-maintained systems can even reach 40 years of service life. The final longevity of your roof depends on four critical factors: 1) Quality of Installation: This is the single most important factor. A flawless installation by a certified crew is paramount. 2) Quality of Materials: The number of plies (e.g., a 4-ply system will outlast a 3-ply system) and the quality of the asphalt and felts used make a significant difference. 3) Local Climate Conditions: The intense UV exposure and storm frequency in Alabama can be demanding, making proper installation even more critical. 4) Consistency of Preventative Maintenance: Regular inspections and minor upkeep, like ensuring drains are clear, will maximize the roof’s lifespan.

Can you install a new roof over an old built-up roof?

In almost all cases, the answer is an emphatic no. Installing a new roof system over an existing built-up roof, a practice known as a “roof-over” or “recover,” is not recommended by roofing professionals and is prohibited by most building codes if more than one roof system is already in place. This practice introduces several severe risks:

- Excessive Weight: BUR systems are heavy. Adding a second roof can easily exceed the load-bearing capacity of your building’s structure, leading to dangerous sagging or even collapse.

- Trapped Moisture: Any moisture present in the old roof will be trapped, creating a perfect environment for mold and rot. This trapped moisture will also cause blisters and premature failure of the new roof from below.

- Voided Warranties: Virtually all roofing manufacturers require a full tear-off to a clean, sound deck for their most robust warranties to be valid. A roof-over will void the warranty.

- Hidden Damage: Covering the old roof makes it impossible to inspect the underlying structural deck. This means any existing rot, corrosion, or damage is left unaddressed, compromising the foundation of your new roof.

A full tear-off is the only correct, professional approach. It ensures your new roof is installed on a solid, dry, and inspected foundation, which is essential for achieving its maximum performance and lifespan.

Is a built-up roof a good choice for my commercial building?

Yes, a built-up roof remains an excellent choice for many commercial and industrial buildings, particularly those with low-slope or flat designs that require maximum durability. Its primary advantages for commercial properties are clear:

- Outstanding Durability and Redundancy: The multi-layer construction is its greatest asset. If the top layer is punctured or damaged, the underlying layers continue to provide robust waterproofing protection. This redundancy is a significant advantage over single-ply systems.

- Superior Puncture and Traffic Resistance: BUR systems are highly resistant to damage from foot traffic, dropped tools, hail, and storm debris. This makes them ideal for roofs that house heavy HVAC equipment requiring regular maintenance.

- Excellent Waterproofing: When installed correctly, the monolithic, seamless membrane created by layers of hot-mopped asphalt offers exceptional, time-proven protection against water intrusion.

These features make BUR systems a reliable, cost-effective, and long-term solution for warehouses, manufacturing plants, schools, and retail centers where roof integrity and operational continuity are paramount.

Can my built-up roof be repaired instead of replaced?

It depends entirely on the age and condition of the roof. If the roof is relatively young (e.g., under 15 years old) and the damage is localized—such as a single puncture, a crack in a piece of flashing, or a few small blisters—then professional repairs are often a viable and cost-effective solution. However, if the roof is exhibiting systemic issues like widespread alligatoring, extensive blistering, exposed felts across large areas, or chronic leaks in multiple locations, you have reached the point of diminishing returns. Continuously patching a roof that is fundamentally failing is not a sound financial strategy. A thorough professional inspection is the only way to determine if you are dealing with isolated, repairable issues or a system that has reached the end of its service life.

What kind of maintenance does a new built-up roof require?

While BURs are tough, they are not “set it and forget it” systems. Proactive, preventative maintenance is key to maximizing their long lifespan. A good maintenance plan, typically performed twice a year (spring and fall), should include:

- Thorough cleaning of debris like leaves, branches, and trash that can clog drains and hold moisture against the roof surface.

- Inspection and clearing of all drains, scuppers, and gutters to ensure positive drainage.

- Detailed inspection of all flashing at parapet walls, curbs, and penetrations.

- Checking for any early signs of damage, such as blisters, deep cracks, or areas of eroded gravel.

- Keeping a detailed log of all inspections and repairs for warranty purposes.

Secure Your Property with a Professional BUR Replacement

A built-up roof replacement is more than a maintenance task; it is a critical investment in your commercial property’s long-term value, safety, and operational continuity. By understanding the warning signs of a failing roof, the details of the installation process, and the factors that influence cost, you can make a confident and informed decision. The proven durability and redundant protection of BUR systems make them a formidable choice for any building owner who prioritizes resilience, but this world-class performance is only achievable when the system is installed with precision and expertise.

Don’t wait for a catastrophic failure. A planned, proactive replacement is always far less costly and disruptive than an emergency response to a major leak that has damaged your inventory, equipment, and building interior. If you see the tell-tale signs of widespread alligatoring, are battling persistent leaks, or know your roof is over 20 years old and requires increasingly frequent repairs, the time to act is now.

At Prime Roofing & Restoration, we merge premium, industry-leading materials with decades of hands-on expertise to deliver commercial roofing solutions that are built to last. Our core mission is to build lasting relationships with our clients through unwavering reliability, transparent communication, and superior craftsmanship. We are fully licensed and insured, and our team of experts is committed to protecting your investment as if it were our own.

Your next step is simple but crucial.

If you suspect your built-up roof is nearing the end of its useful life or have noticed any of the warning signs we’ve outlined, don’t gamble with your property’s protection. Contact us today to schedule a comprehensive, no-obligation assessment with our experienced Commercial Roofing Services team.

Prime Roofing & Restoration

Address: 123 Main Street, Alabaster, AL 35007

Phone: (205) 555-0199

We proudly serve commercial property owners throughout Alabaster, Hoover, Pelham, Shelby County, and the wider Central and Southern Alabama regions. When you choose Prime Roofing & Restoration, you’re not just getting a new roof—you’re getting the peace of mind that comes from working with true professionals who stand behind their work with integrity.