Why Finding the Right Industrial Roofing Company Matters

Finding the right industrial roofing companies near me that truly understand the unique, high-stakes demands of industrial facilities can mean the difference between decades of reliable, worry-free protection and a constant cycle of costly emergency repairs and operational disruptions. Industrial roofs are not just larger versions of residential roofs; they are complex systems engineered to withstand extreme challenges. These can range from constant chemical exposure from manufacturing processes and heavy equipment vibrations to extensive foot traffic and the sheer weight of large-scale HVAC systems. For businesses in Alabama, partnering with a local company that provides expert roofing solutions is a critical decision that ensures your most valuable asset—your operational capacity—is protected.

Quick Answer for Industrial Roofing Companies Near Me:

- Look for specialized experience: Prioritize contractors who focus on industrial and commercial projects, not residential roofing. Their portfolio should demonstrate success with facilities of similar size and complexity to yours.

- Verify licensing and insurance: This is non-negotiable. Confirm they hold adequate general liability and workers’ compensation insurance to shield your business from any potential liability during the project.

- Check manufacturer certifications: Top-tier contractors are certified by leading manufacturers (like GAF, Carlisle, or Firestone), granting you access to superior materials and the best NDL (No Dollar Limit) warranties.

- Ask about technology: Modern roofers use tools like drone inspections for comprehensive visual data and thermal imaging (infrared thermography) to detect hidden moisture without destructive testing.

- Evaluate maintenance programs: A proactive maintenance plan is proven to extend roof life by up to 50%, turning a capital expense into a manageable operational cost.

- Get detailed, itemized estimates: Costs for industrial roofing typically range from $5-15+ per square foot, but a trustworthy estimate will break down every line item, from tear-off to disposal and labor.

Industrial facilities require contractors who understand the critical need for zero downtime during repairs. As industry research consistently shows, up to 80% of roof leaks originate from just 20% of the roof surface—often at penetrations and seams—making expert diagnosis essential to avoid unnecessary, expensive work. My name is Bill Spencer, and with over five years of experience in this field, I’ve learned that the best contractors combine deep technical knowledge with a genuine understanding of your operational needs, ensuring the roofing project enhances, rather than hinders, your business.

Key terms for industrial roofing companies near me:

- EPDM roof replacement

- EPDM roof system

7 Telltale Signs Your Industrial Roof Needs Professional Attention

Your industrial roof works tirelessly, 24/7, to shield your operations, inventory, and personnel from Alabama’s demanding weather and the specific rigors of industrial use. Recognizing the early warning signs of roof distress can be the key to preventing catastrophic failures, expensive secondary damage, and crippling operational shutdowns. If your search for industrial roofing companies near me was prompted by a specific concern, it’s likely you’ve spotted one of these seven critical signals that your roof requires immediate professional help.

- Visible Leaks or Moisture Infiltration: This is the most obvious and urgent warning. Water stains on ceiling tiles, active drips during rain, or unexplained puddles on the factory floor are clear indicators of a breached roof barrier. Beyond the slip-and-fall hazard, these leaks can cause devastating damage to sensitive machinery, ruin valuable inventory, and create the perfect environment for toxic mold growth within your facility’s walls and ceiling.

- Ponding or Standing Water: If water remains on your flat roof for more than 24-48 hours after a rainstorm, you have a serious problem. Water is incredibly heavy, weighing about 8.34 pounds per gallon. A large area of ponding water can add thousands of pounds of unintended dead load to your roof structure, potentially exceeding its design capacity. Furthermore, standing water magnifies the sun’s UV rays, accelerating the deterioration of the roof membrane beneath it.

- Cracks, Blisters, or Bubbles on the Surface: These imperfections are clear signs of an aging or failing roof membrane. Blisters and bubbles are caused by trapped air or moisture that expands under the heat of the sun, stretching the membrane and creating a weak spot. Cracks and crazing often result from UV degradation and thermal shock, which makes the material brittle. Each of these is a future leak waiting for the next rainstorm.

- Damaged or Deteriorating Flashing: Flashing is the metal or membrane material that seals the transitions around roof penetrations like pipes, vents, skylights, and HVAC units. Industry data consistently shows that failed flashing is a primary source of leaks. The constant expansion and contraction of different materials (e.g., a metal vent and a TPO membrane) puts immense stress on these details, causing them to separate, tear, or degrade over time.

- Unexplained Spikes in Energy Bills: Your roof is a critical component of your building’s thermal envelope. A sudden, significant jump in your heating or cooling costs is often a red flag for compromised or wet roof insulation. When insulation becomes saturated with water, its R-value (resistance to heat flow) drops to nearly zero, forcing your HVAC systems to work much harder to maintain the building’s temperature.

- Visible Wear, Tear, and Debris: A visual inspection can reveal a lot. On asphalt-based roofs, look for widespread granule loss, which exposes the underlying material to damaging UV rays. On single-ply roofs, check for separating or peeling seams. On metal roofs, look for rust, loose fasteners, or panels that have shifted. An accumulation of debris can also clog drains, leading to ponding water.

- Sagging, Drooping, or Distorted Roof Deck: This is the most alarming sign and constitutes a true emergency. Any noticeable sagging or unevenness in the roof deck could indicate severe structural damage, such as rotted wood decking, corroded metal supports, or compromised joists. This is a major safety threat to everyone in the building and requires immediate assessment by a qualified structural engineer and roofing professional.

Don’t wait for these small problems to escalate into catastrophic failures. Early intervention by a qualified industrial roofer is the key to a manageable, cost-effective repair versus a full, disruptive, and expensive roof replacement.

Learn more about our Commercial Roof Maintenance programs to keep your industrial roof protecting what matters most.

Decoding Your Options: Common & Durable Industrial Roofing Systems

The right roofing system acts as the primary armor for your facility, engineered to protect your operations, assets, and people for decades. When searching for industrial roofing companies near me, it’s crucial to understand the most common and durable options available, as each has distinct advantages suited for different challenges like heavy traffic, chemical exposure, and extreme weather.

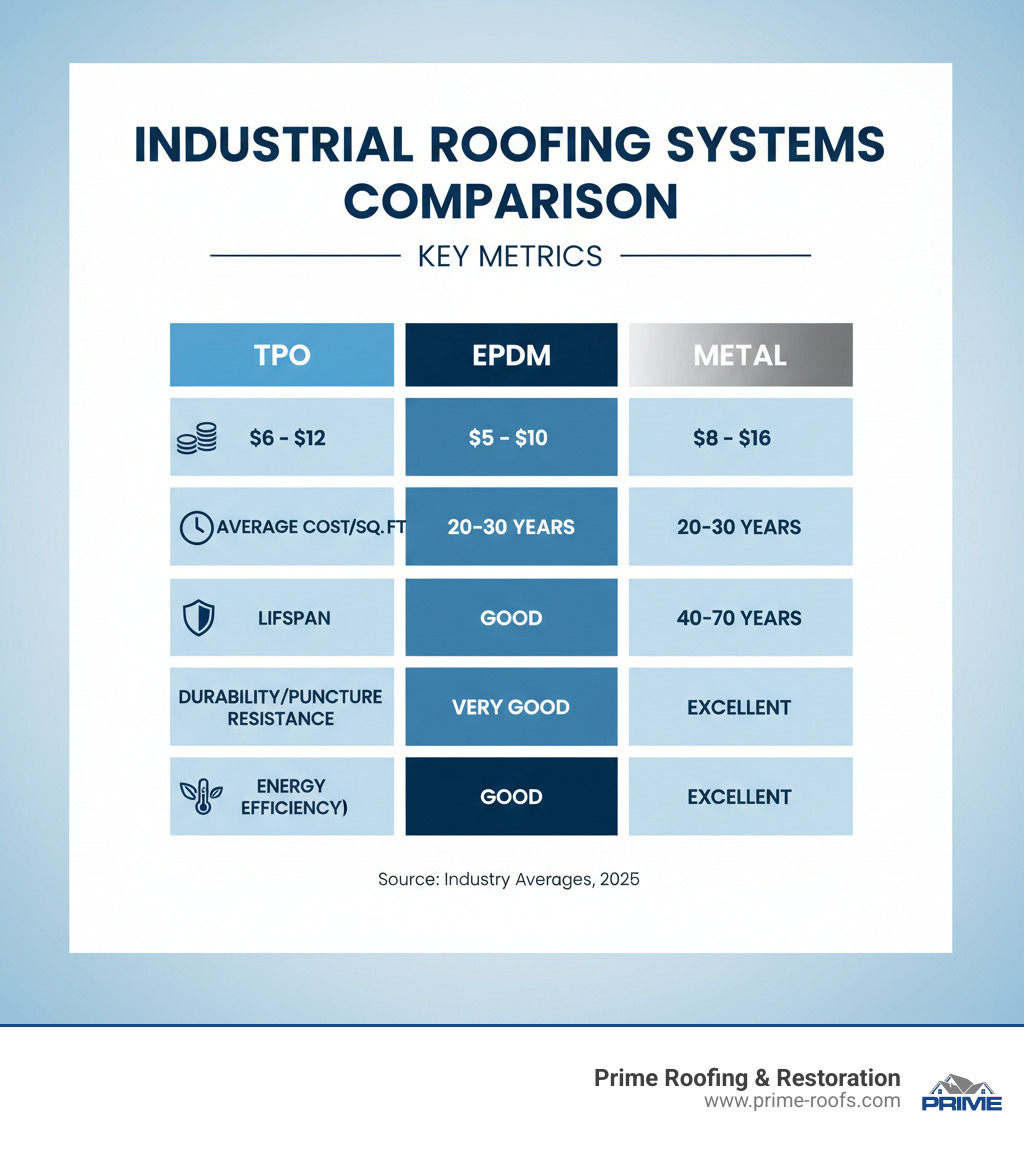

| Roofing System | Average Cost/Sq. Ft. | Lifespan | Durability/Puncture Resistance | Energy Efficiency |

|---|---|---|---|---|

| TPO | $6 – $12 | 20-30 years | Good | Excellent (White) |

| EPDM | $5 – $10 | 20-30 years | Very Good | Good |

| Metal | $8 – $16 | 40-70 years | Excellent | Excellent |

| BUR | $4 – $8 | 20-30 years | Very Good | Moderate |

| Modified Bitumen | $4 – $9 | 15-25 years | Good | Moderate |

| Roof Coatings | $2 – $7 (restoration) | 10-20 years (extension) | Varies (improves existing) | Good to Excellent |

Single-Ply Membranes (TPO & EPDM)

These flexible, sheet-based systems have come to dominate the commercial and industrial flat roof market due to their performance and cost-effectiveness.

- TPO (Thermoplastic Polyolefin): A favorite in warmer climates, TPO’s standard white, reflective surface provides excellent energy savings by reflecting solar heat, reducing the cooling load on your facility—a significant benefit during hot Alabama summers. Its seams are heat-welded with hot air, which fuses the sheets together to create a single, monolithic membrane that is highly resistant to leaks. TPO is also resistant to many chemicals, making it a solid choice for a wide range of industrial applications.

- EPDM (Ethylene Propylene Diene Monomer): Often referred to as a ‘rubber roof,’ EPDM roof systems are renowned for their incredible durability, flexibility, and resistance to weathering. EPDM excels in handling thermal shock and remains pliable in cold temperatures. Its resilience makes it an excellent choice for roofs with complex shapes or numerous penetrations. While traditionally black (which can help melt snow but absorbs heat), white EPDM options are available to improve energy efficiency. An EPDM roof replacement is a long-term, reliable solution.

Metal Roofing

For the ultimate long-term investment in durability and longevity, metal roofing is the undisputed champion, often lasting 40 to 70 years or more. Standing seam metal systems are ideal for low-slope industrial roofs, as they conceal fasteners and allow for the natural thermal expansion and contraction of the metal panels without stressing the attachment points. Metal excels in fire, wind, and hail resistance. Modern metal roofs use advanced coatings like Kynar 500 to resist fading, chalking, and corrosion, ensuring both long-lasting protection and aesthetic appeal.

Built-Up Roofing (BUR)

Often called a “tar and gravel” roof, BUR is the classic, time-tested flat roofing system. It is constructed on-site with multiple alternating layers of bitumen (asphalt) and reinforcing fabrics (plies), then topped with a layer of gravel or a mineral cap sheet. This multi-layer construction provides excellent redundancy and superior puncture resistance, making BUR ideal for roofs that experience heavy foot traffic or have equipment stored on them.

Modified Bitumen

An evolution of BUR, modified bitumen roofing adds polymer modifiers to the asphalt to enhance its performance. There are two main types: SBS (styrene-butadiene-styrene) modified bitumen provides rubber-like characteristics for superior flexibility and elasticity, while APP (atactic polypropylene) modified bitumen has enhanced aging characteristics. It’s a reliable middle-ground choice that combines the multi-layer strength of traditional BUR with modern flexibility and easier installation.

Roof Coatings (Restoration Systems)

For an aging but structurally sound roof, fluid-applied roof coatings offer a powerful alternative to a full replacement. These systems create a seamless, monolithic, and waterproof membrane directly over the existing roof surface. They can extend a roof’s life by 10-20 years for a fraction of the replacement cost. Major benefits include drastically slashing energy consumption (with reflective coatings), sealing countless small leaks simultaneously, and being applied with minimal to no disruption to your facility’s operations.

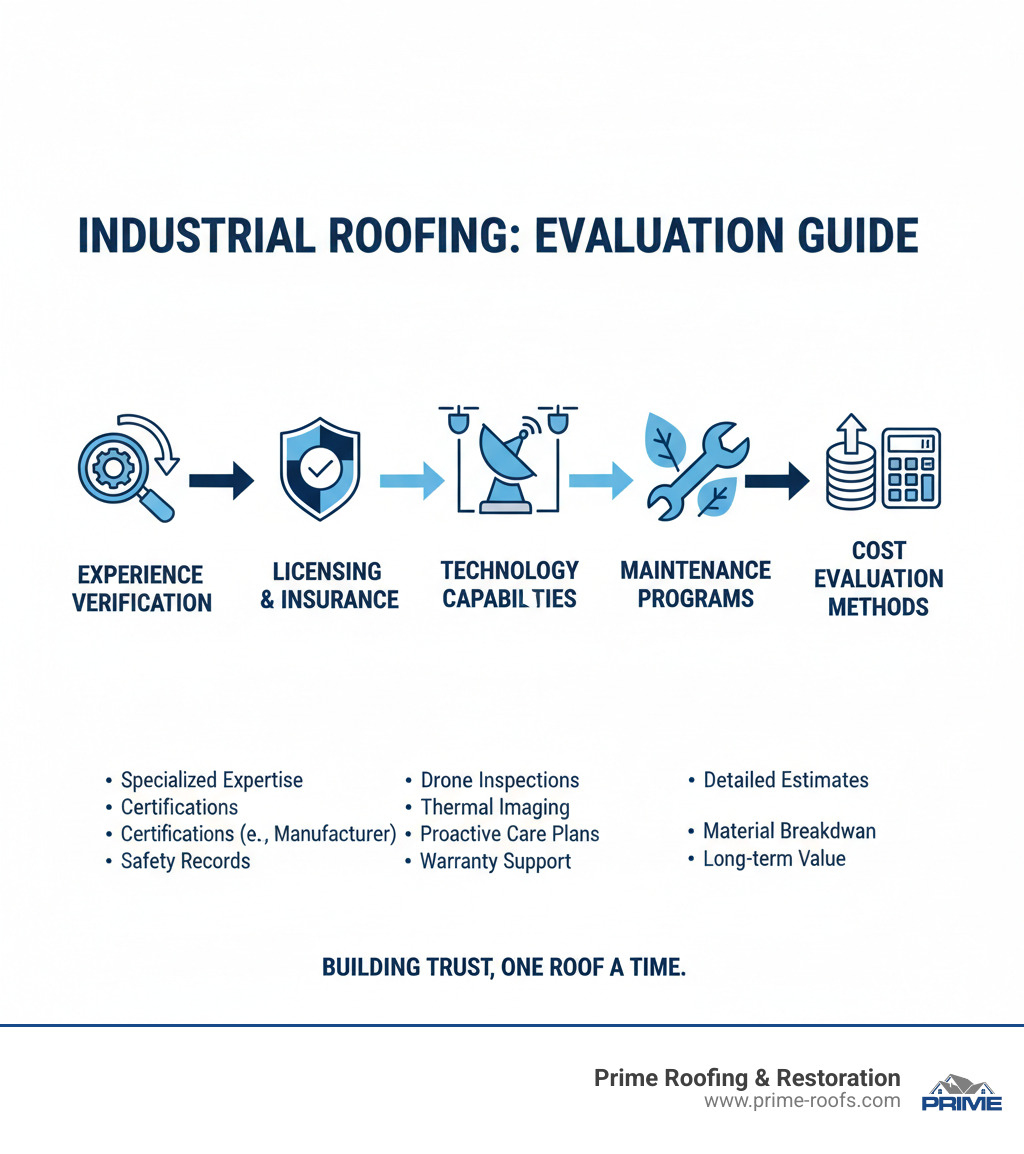

How to Vet Industrial Roofing Companies Near Me: A 5-Step Checklist

Your search for “industrial roofing companies near me” will likely yield numerous options, but not all are created equal. Choosing the right contractor is a critical business decision, as your facility’s safety, operational continuity, and long-term financial health hang in the balance. Use this comprehensive 5-step checklist to methodically vet potential partners and identify a true professional.

Step 1: Verify Deep Experience and Specialization in Industrial Projects

Industrial roofing is a highly specialized field, vastly different from residential or light commercial work. You need a contractor who lives and breathes the challenges of large-scale facilities. Ask pointed questions to gauge their expertise:

- Portfolio Review: Ask to see their portfolio of completed industrial projects. Look for facilities of a similar size, scope, and operational type to your own. View our Project Gallery to see real examples of our industrial expertise.

- Operational Planning: How do they plan to execute the project without interrupting your business? Discuss their strategies for site access, material staging, debris removal, and noise/odor mitigation.

- Problem-Solving: Present them with a complex issue your current roof has. A true expert will be able to discuss potential causes and proven solutions based on past experience.

Step 2: Scrutinize Licensing, Insurance, and Certifications

This step is a non-negotiable gatekeeper. A reputable contractor will readily provide documentation to prove they offer complete protection for your business. Don’t just ask; verify.

- Licensing and Insurance: Confirm they are a licensed roofing contractor in Alabama. Request a certificate of insurance and verify that they carry substantial General Liability (at least $2 million) and Workers’ Compensation policies. Ask to be named as an “additional insured” on their policy for the duration of the project.

- Manufacturer Certifications: Top-tier contractors hold elite-level certifications from manufacturers (e.g., GAF Master Elite, Carlisle Centurion). This proves their crews have been factory-trained on specific installation protocols, which drastically reduces the risk of error and is required for the best system warranties.

- Safety Record: Ask for their Experience Modification Rate (EMR), a number used by insurers to gauge safety performance. An EMR below 1.0 indicates a better-than-average safety record. You can also verify a company’s safety history with OSHA to check for past violations.

Step 3: Inquire About Technology and Inspection Methods

Modern technology enables more accurate, efficient, and non-destructive roof assessments. A forward-thinking contractor invests in these tools to provide better outcomes.

- Drone Inspections: For large, complex industrial roofs, drones provide safe and comprehensive high-resolution visuals. They can capture detailed imagery of every square foot, identifying potential issues that are invisible from the ground or even during a standard roof walk.

- Thermal Imaging (Infrared): This is the gold standard for detecting hidden moisture trapped within a roof system. An infrared camera detects temperature differences on the roof surface, revealing areas of wet insulation that can be targeted for repair before they cause widespread structural damage.

Step 4: Understand Their Maintenance and Warranty Programs

A project’s end shouldn’t be the end of the relationship. A true roofing partner helps you protect your new investment for the long haul. Proactive maintenance is proven to extend a roof’s service life by as much as 50%.

- Proactive Maintenance Plans: A good plan includes semi-annual inspections, cleaning of drains and gutters, removal of debris, and detailed reports with photos to document your roof’s condition. This creates a predictable budget for roof care.

- Warranty Comprehension: Discuss warranty options in detail. Differentiate between a manufacturer’s material warranty and the contractor’s workmanship warranty. The best option is a comprehensive NDL (No Dollar Limit) system warranty from the manufacturer, which covers both labor and materials and is only available through certified installers.

- Emergency Service: Do they offer 24/7 emergency service? Your roof doesn’t operate on a 9-to-5 schedule, and you need a partner who can respond quickly to minimize damage and downtime.

Step 5: Evaluate Cost, Value, and Project Management

The cheapest bid is almost never the best value, especially in industrial roofing. Focus on clear, transparent proposals and a professional project management approach that prioritizes communication and minimizes disruption.

- Detailed, Itemized Estimates: A professional proposal will be a multi-page document that breaks down all anticipated costs: tear-off, disposal, materials, labor, permits, and warranty fees. Beware of vague, one-page quotes.

- Dedicated Project Management: Ask who your single point of contact will be. A dedicated project manager is essential for coordinating with your facility manager, providing regular progress updates, and resolving any issues that arise swiftly and professionally.

Protecting Your Investment: Weather, Maintenance, and Your Industrial Roof

An industrial roof is a significant capital investment, and once installed, it is constantly under assault from the elements—especially in Alabama’s unforgiving climate. A proactive strategy that combines durable, climate-appropriate materials with a disciplined, regular maintenance plan is the only effective defense. For businesses searching for industrial roofing companies near me, understanding these forces is the first step toward long-term asset protection.

The Unrelenting Impact of Weather on Industrial Roofing Systems

Understanding how specific weather phenomena affect your roof allows you to make smarter choices about materials and preventative measures. Key weather-related challenges in Alabama include:

- Intense UV Degradation: The relentless summer sun bombards your roof with ultraviolet radiation, which breaks down the chemical bonds in roofing materials. This causes membranes to become brittle and crack, dries out the vital oils in asphalt-based systems, and leads to the chalking and fading of coatings on metal roofs. Highly reflective surfaces, like white TPO or acrylic coatings, are an effective countermeasure that also lowers energy costs.

- Hail and Wind Damage: Severe thunderstorms can produce hail capable of puncturing membranes and denting metal panels, creating immediate leak points. More insidiously, high winds create powerful uplift forces, especially at the corners and perimeter of the roof. A system that isn’t properly engineered and fastened can be peeled back or lifted off entirely. Look for systems with high wind-uplift ratings from organizations like FM Global to ensure performance during severe weather.

- Extreme Thermal Shock: The daily temperature cycle causes roofing materials to expand and contract. In Alabama, a dark roof surface can easily swing from 70°F at dawn to over 160°F in the afternoon sun. This constant movement puts immense stress on seams, fasteners, and flashing details, leading to material fatigue and eventual failure over time.

- Pervasive Moisture Intrusion: High humidity and frequent, heavy rainfall mean that water is always looking for a way in. It will exploit the tiniest gap in a seam or a pinhole puncture, leading to saturated insulation, corroded metal decks, and potential structural damage from the inside out.

The Overwhelming Financial Case for a Proactive Maintenance Plan

Regular, professional maintenance is the single most effective and highest-ROI activity you can perform to maximize your roof’s lifespan and prevent costly emergencies. The benefits are clear and financially compelling:

- Dramatically Extends Roof Lifespan: Proactive care, including semi-annual inspections and minor repairs, can extend your roof’s service life by up to 50%. This means a 20-year roof can become a 30-year roof, pushing a massive capital expenditure far into the future.

- Prevents Unplanned Production Downtime: For an industrial facility, a surprise roof leak isn’t an inconvenience; it’s a direct threat to production. Identifying and fixing potential failure points before they cause a shutdown is crucial.

- Lowers Total Life-Cycle Costs: The cost of a planned maintenance program is a fraction of the cost of emergency repairs, water damage remediation, and premature roof replacement. A $3,000 annual maintenance plan that delays a $400,000 replacement by eight years provides an enormous return on investment.

- Allows for Predictable Capital Budgeting: Regular inspection reports provide a clear, data-driven picture of your roof’s condition and a reliable forecast for its remaining service life. This allows you to plan and budget for major repairs or replacement years in advance, eliminating financial surprises.

- Maintains Critical Warranty Compliance: Nearly all major manufacturer system warranties require proof of regular, documented maintenance to remain valid. Neglecting maintenance can void your warranty, leaving you fully exposed financially if a major failure occurs.

Our approach to asset management includes detailed inspection reports, photo documentation, and personalized maintenance schedules. Learn more about our comprehensive industrial roofing services and how we can partner with you to protect your business.

Your Local Industrial Roofing Partner in Alabaster, AL

When your facility needs a local expert who intimately understands the specific challenges of protecting industrial assets in Alabama, Prime Roofing & Restoration stands ready to serve. We are proud to be one of the most trusted industrial roofing companies near me for businesses throughout Alabaster, the greater Birmingham metro, and all of Central Alabama.

Finding Reliable Industrial Roofing Companies Near Me in Alabama

Choosing a local contractor isn’t just about convenience; it’s about partnering with a team that has a vested interest in your community’s success and possesses firsthand knowledge of the regional challenges your building faces.

- True Local Expertise: We’ve built, repaired, and maintained roofs through the same Alabama storms you have. We understand how our region’s intense summer heat, high humidity, and risk of tornadic thunderstorms in “Dixie Alley” directly impact roofing material performance and installation requirements.

- Faster Response Times: Being local means we can be on-site in Alabaster and surrounding areas quickly to assess storm damage or perform emergency leak repairs. This rapid response is critical for minimizing water intrusion and reducing your operational downtime.

- Community Trust and Accountability: Our reputation is built one project at a time with our neighbors. We are committed to building lasting relationships with local businesses by delivering exceptional quality and standing behind our work. We know the local building codes and have established relationships with permitting offices in Shelby and Jefferson counties.

Find our expert roofing services in Alabaster, AL and discover why local businesses trust us with their most important physical assets.

Contact Prime Roofing & Restoration

When you’re ready to work with a team that combines national-level expertise with the genuine care and accountability of a local partner, we’re here to help. Contact us to discuss your industrial roofing needs and let us develop a solution that protects your facility for years to come.

Prime Roofing & Restoration

Address: 5 Brown Cir, Alabaster, AL 35007

Phone: (205) 661-8190

Frequently Asked Questions About Industrial Roofing

When facility managers and business owners search for industrial roofing companies near me, a few critical questions about cost, longevity, and repair options always come to the forefront. Here are straightforward, detailed answers to the most common inquiries we receive from Alabama businesses planning a major roofing project.

How much does a new industrial roof cost?

There is no simple, one-size-fits-all price tag, as every industrial roof is unique. However, a general budget range is $5 to $15+ per square foot for a full replacement. The final cost is influenced by a combination of key factors:

- Size and Complexity: While larger roofs have a lower cost per square foot due to economies of scale, a roof with numerous HVAC units, vents, pipes, and skylights will be significantly more expensive due to the intensive labor required for detailed flashing work.

- Choice of Material: As shown in the table above, systems like TPO and EPDM are often more budget-friendly upfront, while high-performance systems like standing seam metal cost more initially but offer a much longer lifespan and lower life-cycle cost.

- Condition of the Existing Roof: If the old roof must be completely torn off (a necessity if there are already two layers, or if the insulation is saturated), this will add significant labor and disposal costs compared to a roof-over or “recover” application.

- Insulation Requirements: Current building codes mandate higher R-values for insulation to improve energy efficiency. The type and thickness of insulation (e.g., Polyisocyanurate) needed to meet these codes can be a major cost driver.

- Accessibility and Logistics: A facility with easy roof access and ample space for material staging will cost less than a project on a tight site that requires cranes or specialized equipment to get materials and crews to the roof.

A detailed, on-site inspection is the only way to get an accurate and reliable quote.

How long does an industrial roof last?

The lifespan of an industrial roof depends heavily on the material chosen, the quality of the initial installation, and the consistency of maintenance. With a proactive maintenance plan, you can generally expect:

- TPO and EPDM: 20-30 years

- Modified Bitumen & BUR: 15-30 years

- Metal Roofs: 40-70+ years

- Roof Coatings (Restoration): Extends life by 10-20 years

The most important takeaway is that regular, professional maintenance can extend a roof’s intended service life by up to 50%. Factors that drastically shorten a roof’s life include poor installation, clogged drains leading to ponding water, unaddressed damage after storms, and a lack of routine inspections. A neglected roof will fail much sooner than one that receives proper, consistent attention.

Can my existing industrial roof be repaired or restored instead of replaced?

In many cases, yes. Premature replacement is one of the biggest unnecessary expenses a facility can incur. A thorough assessment by an honest contractor can determine if a more cost-effective repair or restoration strategy is viable. The decision typically comes down to the condition of the insulation and roof deck.

- Targeted Repairs: This is the best solution for localized issues like a puncture, an open seam, or failed flashing around a single penetration. If the vast majority of the roof is in good shape, simple repairs are fast and economical.

- Roof Restoration: This is an excellent option if the roof membrane is showing widespread aging (e.g., cracking, granule loss) but the underlying insulation and structure are still dry and sound. A fluid-applied restoration coating can add 10-20 years of life at roughly 50-70% of the cost of a full replacement. This process creates a seamless, waterproof membrane over your existing roof with minimal disruption to your operations and can often be treated as a maintenance expense for tax purposes.

- Mandatory Replacement: Replacement becomes necessary when there is widespread moisture saturation in the insulation (typically over 25-30% of the roof area), when the roof deck itself is damaged, or when there are already two or more roof systems layered on top of each other, making a recover against building code.

Conclusion: Secure Your Facility’s Future with the Right Roofing Partner

Your industrial roof is more than just a cover; it is the silent guardian of your entire operation, protecting your people, your equipment, and your ability to do business. Choosing the right partner from the many industrial roofing companies near me is therefore not an incidental expense but a critical business decision with profound, long-term consequences for your facility’s financial health and operational resilience.

A true professional partner brings more than just materials and labor. They bring specialized experience in the unique environment of large-scale industrial projects, understanding that your facility cannot afford downtime. They operate with a transparent commitment to safety and professionalism, backed by proper licensing, comprehensive insurance, and elite manufacturer certifications. The best modern contractors leverage technology like thermal imaging and drone inspections to provide surgically precise assessments, and they champion proactive maintenance plans that can extend your roof’s life by up to 50%, maximizing your return on investment.

Furthermore, the right partner understands the local climate. In Alabama, a roof must be engineered to withstand relentless UV radiation, severe thunderstorms, high humidity, and extreme thermal shock. An expert designs and installs solutions built to thrive in these specific, challenging conditions.

At Prime Roofing & Restoration, we combine data-driven analysis, transparent project management, and a core commitment to building lasting relationships within our community. We don’t just sell roofs; we deliver long-term, warrantied solutions that protect your investment and secure your facility’s future.

Ready to protect your facility with a partner who truly understands the demands of industrial roofing? Contact Us today for a comprehensive roof analysis! Let’s work together to ensure your facility’s most critical asset is secure for decades to come.