Why Your Home Needs Kickout Flashing Repair

Understanding how to repair kickout flashing roof components is not just a matter of routine home maintenance; it is a critical measure to protect your home from the pervasive and costly threat of water damage. Water intrusion is a silent destroyer, responsible for an estimated 40% of all building-related problems. This staggering statistic underscores a fundamental truth: water is the primary adversary to your home’s structural integrity. A small, often overlooked component—the kickout flashing—serves as your first and most important line of defense against this relentless force. When this flashing fails, is improperly installed, or is missing entirely, the resulting water damage can spiral into a financial nightmare, leading to thousands, if not tens of thousands, of dollars in repairs stemming from wood rot, toxic mold proliferation, and compromised siding and foundations. As a trusted Alabama roofing company with deep roots in the community, we’ve witnessed firsthand the devastating consequences of this small oversight. That is why we have created this comprehensive guide, covering everything from the earliest warning signs and detailed inspection techniques to step-by-step repair instructions and clear guidance on when to call a professional. We aim to empower you with the knowledge to safeguard your most valuable asset. For more specific details on protecting your home’s entire exterior envelope, we invite you to visit our roofing service page for a full overview of our expert solutions.

The journey of water from a failed kickout flashing is a destructive one. It begins as a trickle, running down the exterior wall where it should have been diverted into the gutter. This water saturates the siding, seeping behind it and into the wall cavity. Here, it soaks the wooden sheathing and structural framing, creating a perpetually damp environment. This moisture becomes a breeding ground for wood-destroying fungi, leading to structural rot that can compromise the stability of your walls. Simultaneously, this dark, damp space is the perfect incubator for mold, including hazardous varieties like Stachybotrys chartarum (black mold), which can release spores into your home’s air supply and pose significant health risks to your family. As the water continues its downward path, it can damage window and door frames, saturate insulation (rendering it useless), and eventually reach the foundation, where it can cause cracks and further structural issues. What starts as a small roofing flaw can, over time, jeopardize the entire building envelope. This guide will equip you to stop that process before it starts.

What is Kickout Flashing and Why is it Essential for Your Home?

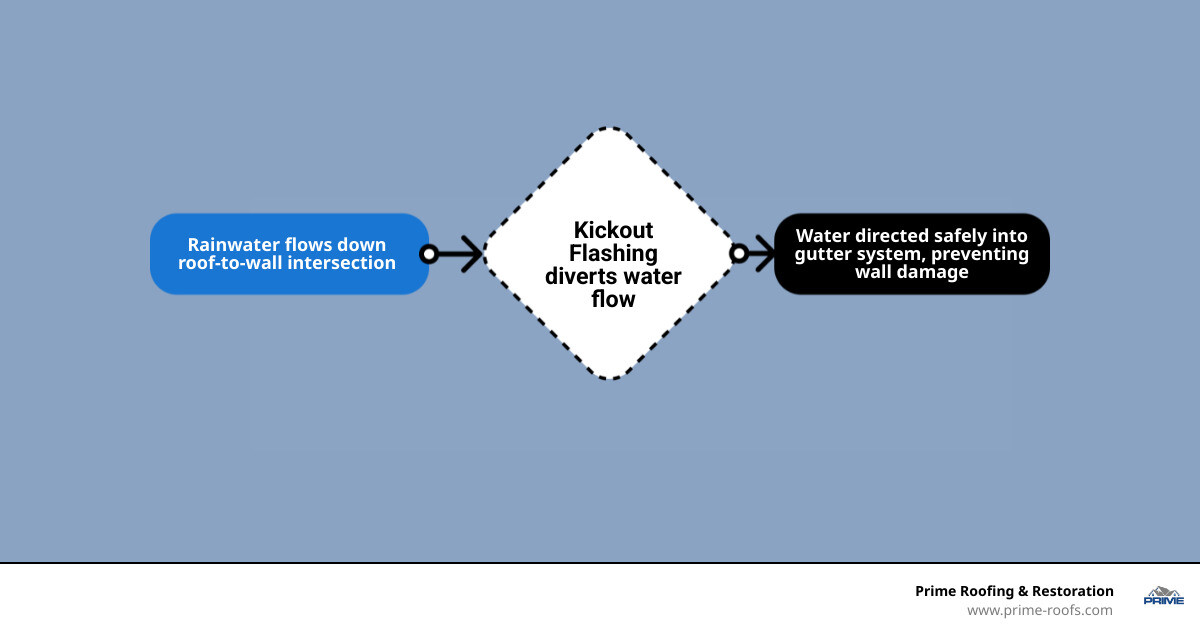

Kickout flashing, also known as a kickout diverter or a diverter flashing, is a specially engineered piece of metal or, less commonly, PVC, located at a critical and vulnerable intersection: where a roof plane terminates against a vertical wall, particularly where a gutter ends. Its singular, vital job is to redirect the concentrated flow of rainwater away from your siding and channel it directly into the gutter system. The shape is key; a proper kickout flashing has an angled fin that extends outward, effectively “kicking” the water away from the wall surface. Without this simple device, the torrent of water coming off the roof would flow directly down the wall, leading to guaranteed water intrusion over time.

The International Association of Certified Home Inspectors (InterNACHI), a leading authority in the home inspection industry, identifies improper or missing kickout flashing as one of the most common and damaging defects found on residential exteriors. Their extensive data highlights this as a leading cause of water intrusion at roof-to-wall connections. Frustratingly, while the International Residential Code (IRC), the model building code used across the United States, has explicitly required this component for over 15 years under section R903.2.1, a shocking number of homes—both old and new—still lack it. This oversight, often due to builder negligence, cost-cutting, or simple ignorance, represents a small detail that can lead to major, expensive headaches for homeowners.

The Critical Consequences of Failure

When kickout flashing is missing, damaged, or improperly installed, your home becomes highly vulnerable to a cascade of compounding problems:

- Catastrophic Water Damage to Walls and Foundations: Water that is not diverted runs down the siding, finding its way into any crack or seam. It saturates the wall sheathing and can travel down the wall studs to the sill plate and foundation. This leads to ugly staining on the exterior, but more importantly, it can cause foundation settlement and cracking as the soil around it becomes oversaturated.

- Structural Rot in Framing and Sheathing: Wood and water are a disastrous combination. Trapped moisture behind the siding creates the perfect conditions for fungal growth, which causes wood to decompose. This rot weakens the structural framing and sheathing of your home, reducing its ability to support loads and resist wind forces. The affected wood becomes soft and spongy, and the damage is often hidden from view until it is extensive.

- Hazardous Mold Growth and Poor Indoor Air Quality: The dark, damp, and unventilated cavity behind your siding is an ideal breeding ground for mold. Mold releases microscopic spores into the air, which can easily infiltrate your home’s living space through gaps and air ducts. This can lead to a host of health problems, including allergies, asthma attacks, chronic sinus infections, and other respiratory issues, creating a significant health hazard for your family.

- Accelerated Siding Deterioration: No siding material is immune to constant water flow. Wood siding will quickly rot, crack, and lose paint. Vinyl siding can warp and discolor. Fiber cement, while durable, can absorb moisture at its cut edges, leading to delamination and spalling. Stucco and Exterior Insulation and Finish Systems (EIFS) are particularly notorious for hiding massive amounts of water damage and rot for years before any external signs become visible.

- Compromised Roof and Gutter Systems: The problem isn’t isolated to the wall. Water that isn’t properly directed into the gutter can overflow its edges, saturating the fascia and soffit boards and causing them to rot. It can also back up onto the roof deck itself, leading to shingle damage and roof leaks in other areas.

Knowing how to repair kickout flashing roof components is the key to preventing this entire chain reaction of destruction.

Why Kickout Flashing Fails

Understanding the root cause of the failure is essential for implementing a permanent and effective fix. Failures almost always fall into one of these categories:

- Poor or Incorrect Installation: This is the most common culprit. The flashing may be installed at the wrong angle (it should be at least 110 degrees to effectively shed water), inadequately sealed against the wall, or fastened with incorrect, non-corrosion-resistant nails that rust and create leaks. In some egregious cases, installers bend the flashing inward, actively funneling water into the wall assembly.

- Corrosion or Rust: The material itself can fail. Galvanized steel flashings, a common choice for builders, can rust through in as little as 10-15 years, especially in the humid, salt-laden coastal air of places like Gulf Shores, Alabama. This corrosion creates pinholes or larger breaches that allow water to pass through.

- Storm or Wind Damage: Severe weather events can wreak havoc on flashing. High winds can lift and bend the flashing out of position, while hail can create dents that disrupt water flow or even puncture the metal.

- Material Fatigue and Thermal Movement: Over decades, the constant cycle of heating and cooling causes the metal to expand and contract. This thermal movement can eventually lead to stress cracks or cause the flashing to warp and pull away from the wall, breaking the watertight seal.

- Overlooked Building Codes and Supply Issues: Despite being a code requirement for well over a decade, some contractors still omit this crucial step. This can be due to a lack of training, a desire to cut costs, or even inconsistent availability of prefabricated kickout flashings at local supply stores, leading them to attempt to fabricate a less effective version on-site.

Kickout Flashing vs. Other Roof Flashings

To fully protect your home, it’s important to understand that kickout flashing is part of a larger, integrated system of flashings. Each type has a specific role:

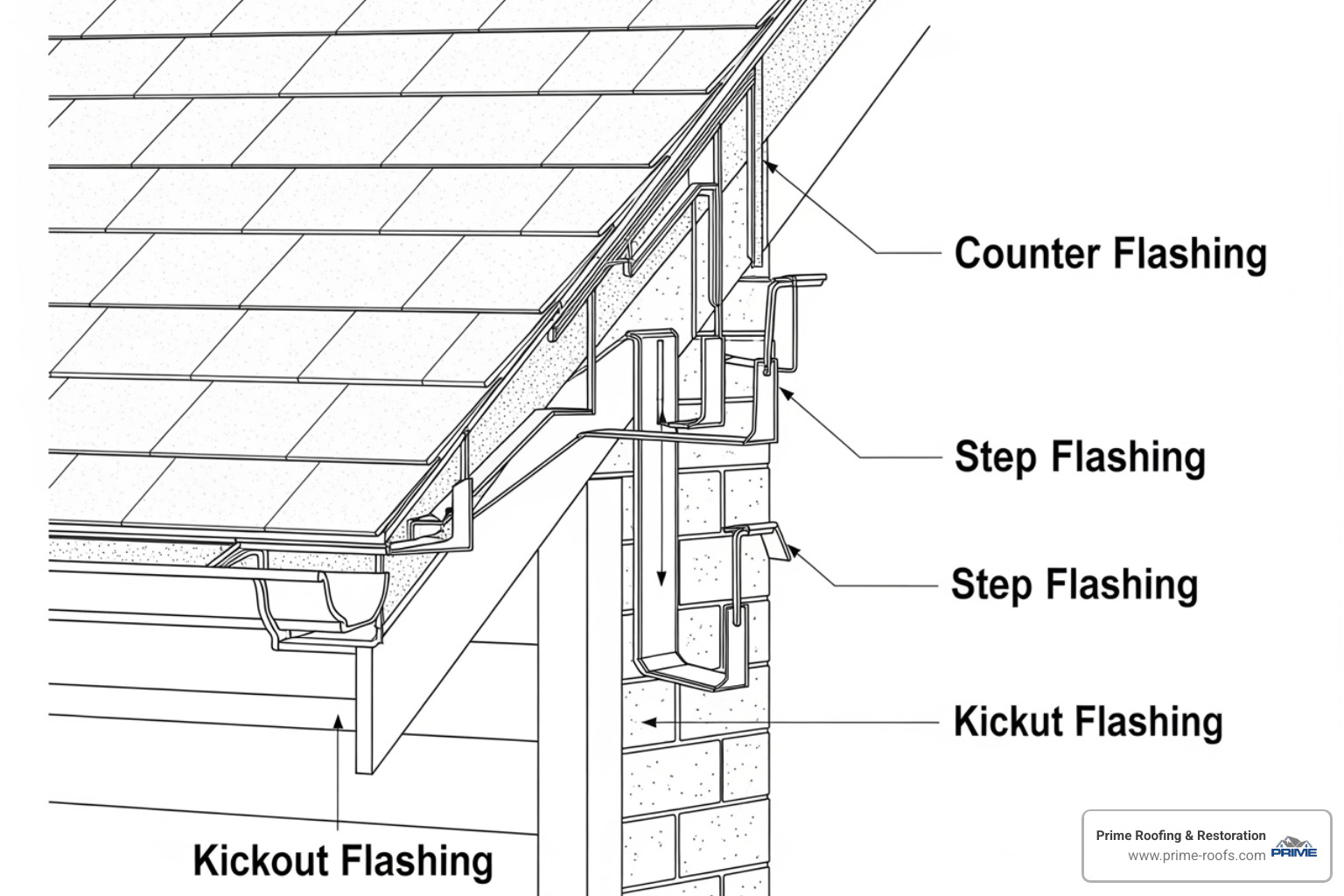

- Kickout Flashing: Its unique role is to handle the termination point. It’s the final piece in the system, located at the lower end of a roof-to-wall intersection, designed to divert water sideways away from the wall and into the gutter.

- Step Flashing: These are individual L-shaped pieces of metal that are woven into the shingle courses along the angled joint where a roof meets a vertical wall. Each piece overlaps the one below it, channeling water down the roof plane toward the kickout flashing.

- Counter Flashing (or Apron Flashing): This is a separate piece of flashing that covers the top edge of the step flashing. It’s typically embedded into a mortar joint on a brick or stone wall or installed behind the siding on a framed wall. Its job is to prevent water from getting behind the step flashing from above.

For complete, long-term protection, all three of these flashing types must be present, correctly installed, and working together as a cohesive system.

Spotting Trouble: 5 Signs Your Kickout Flashing Needs Repair

Catching kickout flashing problems early is the key to preventing minor issues from escalating into major structural damage. Proactive inspection, especially after a significant Alabama storm, can save you immense cost and frustration. Here are five clear indicators that it’s time to schedule a repair kickout flashing roof job.

- Water Stains on Siding or Interior Walls: This is the most direct and alarming sign. Look for dark streaks, discoloration, or patchiness on the exterior siding directly below a roof-wall intersection. These stains are the tracks left by water that is not being properly diverted. If you see damp spots, peeling paint, or discoloration on interior ceilings or the upper portions of walls, it signifies that water has already breached your home’s defenses and is leaking inside.

- Peeling, Bubbling, or Blistering Paint Near Rooflines: Paint is more than just decorative; it’s a protective layer. When water gets trapped behind a painted surface, it creates vapor pressure that pushes the paint film away from the substrate, causing it to bubble, flake, or peel. This is an extremely common sign of moisture intrusion near the roof’s edge and a strong indicator of a flashing failure.

- Visible Corrosion, Holes, or Gaps in the Flashing: A physical inspection of the flashing itself can reveal its condition. Get a safe vantage point and look for any signs of rust (on steel), white powdery oxidation (on aluminum), cracks, pinholes, or visible gaps between the flashing and the wall or roof. Any breach in the metal’s surface means it is no longer a solid, continuous barrier against water and requires immediate attention.

- Cracked, Warped, or Rotted Siding Below Roof Intersections: Siding that is constantly exposed to moisture will inevitably fail. Wood siding will begin to soften, rot, or warp. Stucco may develop cracks or show signs of efflorescence (a white, powdery deposit left by evaporating water). Fiber cement siding can delaminate or swell. If you can press on the siding below the roofline and it feels soft or spongy, you likely have a significant, long-term leak.

- Persistent Moisture or Musty Odors in the Attic or Upper Rooms: Your nose can often detect a problem before your eyes do. A persistent damp, earthy, or musty smell in your attic, closets, or upper-level rooms is a tell-tale sign of a hidden leak and the resulting mold or mildew growth. This odor often originates from failed flashing allowing water into the wall or attic space.

Detailed Visual Clues on Your Home’s Exterior

When performing a walk-around inspection of your home’s exterior, arm yourself with a pair of binoculars and look for these specific trouble signs with a critical eye:

- Water Streaks or Discoloration on Siding: Don’t dismiss these as simple dirt. These marks are a map that pinpoints exactly where water is escaping the roof-flashing system and running down the wall. Note their precise location.

- Cracked or Bubbling Stucco: Stucco and EIFS are notorious for hiding underlying damage. Look closely for hairline cracks originating from the roof-wall corner. Tap on the stucco; a hollow sound can indicate delamination from the sheathing due to moisture. Look for a white, powdery residue known as efflorescence, which signals that water is moving through the masonry and evaporating on the surface.

- Rust Stains or Visible Gaps in Flashing: Any flashing that is bent, dented, rusted, or has pulled away from the wall is failing. Pay close attention to the seams and corners. The metal should be tightly integrated with the wall and roof, with no gaps for water to enter.

- Algae, Moss, or Mold Growth on Exterior Walls: Green or black growth on your siding, especially in a concentrated area below a roofline, is a dead giveaway of consistent moisture. These organisms cannot thrive without a steady supply of water, often provided by a faulty kickout flashing.

- Insect Activity: Termites and carpenter ants are drawn to moist, soft wood. An unusual concentration of these pests around a roof-wall intersection can be an secondary sign of water damage and rot occurring within the wall.

Interior Signs of a Pervasive Leak

Sometimes, the first clues that something is wrong with your exterior flashing appear inside your home. Be vigilant for these signs:

- Damp Spots or Stains on Ceilings or Upper Walls: This is a classic and urgent sign of a roof or flashing leak. The stain may appear brownish or yellowish and may feel damp to the touch, especially after rain.

- Pervasive Musty Odor in Attic or Upper Floors: This is an early warning of hidden moisture and potential mold growth long before any visible signs appear. Don’t ignore a persistent musty smell; investigate its source.

- Peeling Paint or Sagging Wallpaper: Just like on the exterior, moisture seeping through your drywall from an external source will cause interior finishes to fail. Paint will peel, and wallpaper seams will separate or sag.

- Visible Daylight Through Attic Roof-to-Wall Intersections: On a bright day, go into your attic (if it’s safe to do so) and look at the area where the roof meets the exterior walls. If you can see any daylight, you have a serious breach that provides a direct path for water, wind, and pests to enter your home. This requires immediate professional repair.

A Homeowner’s Guide to Repairing Kickout Flashing Roof Damage

Addressing a failing kickout flashing roof component promptly is one of the most important preventative maintenance tasks you can undertake. While some minor fixes might seem approachable, it is crucial to recognize that working on a roof is inherently dangerous and requires specific skills and knowledge. Any repair involving flashing is a multi-layered process where a small mistake can lead to bigger leaks. Safety must always be your non-negotiable first priority.

Safety First: Essential Precautions for Any Roof Work

Before you even consider climbing a ladder, you must internalize and follow these essential safety precautions. Failure to do so can result in serious injury or death.

- Use a Sturdy, Well-Placed Ladder: Your ladder is your lifeline. Ensure it is rated for your weight and the weight of your tools. Place it on firm, level ground. Follow the 4-to-1 rule: for every four feet of height, the base should be one foot away from the wall. The ladder must extend at least three feet above the roof eave to provide a safe handhold for transitioning on and off the roof.

- Wear Proper, Slip-Resistant Footwear: Roofing surfaces, covered in loose granules, can be as slick as ice, even when dry. Wear soft-soled, high-traction boots or shoes that provide excellent grip. Avoid leather-soled shoes at all costs.

- Use a Safety Harness and Fall Arrest System: For any roof with a significant pitch (generally 6/12 or steeper) or any second-story work, a personal fall arrest system (PFAS) is non-negotiable. This system includes a full-body harness, a lanyard, and a secure anchor point. It is your last line of defense in a slip or fall.

- Avoid Poor Weather Conditions: Never work on a wet, icy, or windy roof. Moisture dramatically reduces traction, and a sudden gust of wind can easily cause a loss of balance. Also, be mindful of the temperature; shingles can become brittle and crack in the cold or become soft and easily damaged in extreme heat.

- Be Acutely Aware of Power Lines: Look up and around before placing your ladder. Identify the location of all overhead power lines. The rule is to stay, and keep your tools and ladder, at least 10 feet away from any power line.

- Work with a Partner: Whenever possible, work with a spotter on the ground. This person can stabilize the ladder, pass tools, and, most importantly, call for help immediately in case of an accident.

Tools and Materials for a Professional-Grade Job

Gathering all necessary tools and materials before you start is crucial for both safety and efficiency, as it minimizes dangerous trips up and down the ladder.

- Pry Bar / Flat Bar: To gently lift shingles and pry away old nails and flashing.

- Utility Knife with Hook Blades: For cleanly cutting shingles and underlayment.

- Hammer and Corrosion-Resistant Roofing Nails: Use 1 ¼” hot-dip galvanized or stainless steel nails.

- Caulk Gun and High-Quality Roofing Sealant: Use a tripolymer or polyurethane sealant that is ASTM C920 compliant and rated for exterior use. Do not use silicone.

- Replacement Kickout Flashing: Choose a durable, code-compliant material. Prefabricated, seamless aluminum or copper flashings (like those from DryFlekt) are highly recommended for their reliability and correct angle.

- Ice and Water Shield Membrane: A self-adhering, rubberized asphalt membrane that provides a critical secondary layer of waterproof protection.

- Tin Snips (Aviation Snips): To cut or shape metal flashing if necessary.

- Safety Gear: Heavy-duty gloves, safety glasses, and the fall protection equipment mentioned above.

Step-by-Step Guide to a Full Replacement of Kickout Flashing

This guide details a full replacement, which is the only reliable long-term solution for a failed or improperly installed flashing. Sealing or patching is a temporary fix at best.

- Clear and Prepare the Work Area: Remove all leaves, pine needles, and other debris from the roof section. This ensures a safe workspace and allows for a thorough inspection of the surrounding shingles and decking.

- Carefully Remove Siding and Shingles: This is a delicate process. Use a flat bar to gently break the seal on the shingles above and around the flashing. Use the bar to pry out the nails holding them. You will likely need to remove 2-3 courses of shingles in a 2-3 foot wide area. Next, carefully cut back or remove the piece(s) of siding covering the vertical part of the flashing to fully expose the work area.

- Remove the Old, Failed Flashing: With the area exposed, gently pry away the failed kickout flashing and any associated step flashing. Take care not to damage the underlying roof deck or the wall sheathing and weather-resistive barrier (WRB).

- Inspect and Repair All Underlying Damage: This is the most critical step. Thoroughly examine the exposed roof decking and wall framing for any signs of water damage—discoloration, softness, or crumbling. Probe the wood with a screwdriver. All soft, damp, or rotted wood must be completely cut out and replaced with new, sound material before proceeding. Skipping this step means you are just covering up a structural problem.

- Install a New Ice and Water Shield: Apply a new piece of self-adhering waterproof membrane. It should extend from the roof deck up the wall by at least 8-12 inches, creating a seamless, waterproof pan in the corner. This provides a crucial secondary water barrier in case the primary flashing system is ever breached.

- Secure the New Kickout Flashing: Position the new prefabricated kickout flashing at the correct 110-degree angle. Ensure its base is properly integrated with the first piece of step flashing and that its diverter fin will effectively direct water into the gutter. The vertical portion must be installed over the wall’s weather-resistive barrier (house wrap). Secure it to the roof deck with two roofing nails at its top corners.

- Reinstall Step Flashing, Shingles, and Siding: Working your way up, reinstall the step flashing, weaving each piece with a new course of shingles. Each shingle must cover the top portion of the step flashing below it. The siding should then be reinstalled, leaving a mandatory 1- to 2-inch gap between the bottom edge of the siding and the roof surface. This gap is critical to prevent the siding from wicking moisture.

- Seal All Edges and Fasteners: Apply a neat bead of high-quality roofing sealant to the top edge of the flashing where it meets the wall and cover any exposed nail heads to create a final, durable watertight seal. Do NOT apply sealant to the bottom edge of the flashing on the roof deck, as this can trap water.

DIY vs. Calling a Professional: Making the Right Choice

When you discover a problem with your repair kickout flashing roof system, you face a critical decision: should you attempt the repair yourself, or is it time to hire a professional roofing contractor? The correct choice hinges on an honest assessment of the scope of the damage, your personal skills and experience, your comfort level with heights, and the complexity of your roof’s design.

When a DIY Repair Might Be Feasible

A do-it-yourself fix may be a viable option, but only if you are a seasoned home repair enthusiast with direct roofing experience and the situation meets a very specific set of criteria:

- Extremely Minor Damage: The issue is limited to a very small, localized gap or a tiny rust spot on an otherwise sound flashing that can be meticulously cleaned, primed, and sealed as a temporary measure.

- Simple Resealing Task: The flashing itself is structurally intact, correctly shaped, and properly installed, but the old sealant has dried out and cracked. In this case, carefully removing the old sealant and applying a new, high-quality bead may be sufficient.

- Significant Roofing Experience: You are not a novice. You have previously worked with roofing materials, understand the principles of water-shedding and shingle-fashion layering, and know how to handle roofing tools safely and effectively.

- Easily Accessible, Low-Slope Roof: The work area is on a first-story roof with a low pitch (e.g., 4/12 or less), making it relatively safe to access and work on without specialized fall protection equipment.

- Confirmed Absence of Structural Damage: Your thorough inspection reveals absolutely no signs of moisture, rot, or deterioration in the underlying roof deck or wall sheathing. The problem is confined solely to the flashing itself.

Even in these ideal scenarios, remember that a small mistake in sealing or layering can trap water instead of shedding it, leading to more significant and expensive problems down the road. If you have any doubt, it is always wiser to err on the side of caution.

Red Flags: When to Immediately Call a Licensed Roofing Contractor

In the vast majority of cases, repairing or replacing kickout flashing is a job best left to the experts. It is the safest, most effective, and ultimately most cost-effective choice. We strongly recommend contacting a licensed and insured expert like Prime Roofing & Restoration for any of the following situations:

- Discovery of Extensive Rot or Water Damage: If your inspection reveals any soft, spongy, or discolored wood in the roof decking, sheathing, or wall framing, the job has escalated from a simple flashing repair to a structural carpentry repair. This requires a professional to properly assess the damage and restore the home’s structural integrity.

- Steep, High, or Complex Rooflines: Professionals possess the mandatory safety equipment (harnesses, ropes, roof jacks), specialized training, and insurance to work safely on high, steep, or architecturally complex roofs. The risk of a life-altering fall is too great for an amateur.

- Uncertainty About Building Codes: A licensed contractor is current on all local and state building codes, including specific requirements for flashing integration in Alabama. This ensures your repair is compliant, will pass inspection, and is performed to a professional standard.

- Lack of Proper Tools or Safety Gear: Attempting a roof repair without the correct tools and, most importantly, the proper safety gear is both dangerous and likely to result in a subpar, leaky repair. The cost of buying a full fall-arrest system alone can be more than the labor cost for a professional.

- Persistent Leaks After a DIY Attempt: If you’ve already tried to fix the leak and it continues, it’s a clear signal that the problem is more complex than you realize. Professionals have diagnostic tools and experience to trace the water path to its true source, which may not be where the leak is appearing.

Why Choose Prime Roofing & Restoration?

For an expert assessment and a repair you can trust, contact our team. We have years of experience diagnosing and permanently solving water intrusion issues for homeowners throughout the region. We are fully licensed, insured, and committed to quality craftsmanship.

Prime Roofing & Restoration

Address: 123 Main Street, Alabaster, AL 35007 (Example Address)

Phone: (205) 555-7663

Website: https://www.prime-roofs.com/

For service in your area, contact our dedicated roofers in Alabaster, AL.

Understanding Professional Repair Costs

Investing in a professional repair kickout flashing roof service is an investment in preventing far more extensive and expensive water damage in the future. While costs can vary based on the specifics of the job, it’s helpful to understand the potential range and the factors that influence the final price.

- Average Cost Range: A straightforward replacement of a single kickout flashing with no underlying damage might fall between $250 and $750. If significant rot repair is needed, the cost can easily rise to $1,500 – $3,000 or more, depending on the extent.

- Key Factors Influencing Cost:

- Extent of Damage: A simple reseal is the least expensive, while a full replacement involving carpentry to fix rotted sheathing and framing will be the most expensive.

- Materials Used: High-end materials like 20 oz. copper or heavy-gauge Kynar-coated aluminum will cost more than standard galvanized steel or thinner aluminum, but offer a much longer lifespan.

- Labor and Roof Complexity: Labor is a significant cost factor. A steep, high, or difficult-to-access roof will require more time, safety equipment, and thus, higher labor costs.

- Scope of Siding Work: The type of siding on your home can also affect the cost. Removing and reinstalling a few pieces of vinyl siding is much simpler and cheaper than dealing with brick, stone, or stucco.

Always insist on a detailed, written estimate from any reputable contractor that clearly outlines the scope of work, materials to be used, labor costs, and warranty information before any work begins.

Frequently Asked Questions about Kickout Flashing

As specialists in protecting the building envelope, we find that homeowners often have questions about this vital but little-known roof component. Here are detailed answers to some of an most common inquiries we receive regarding kickout flashing.

How long should properly installed roof flashing last?

The lifespan of your roof flashing is highly dependent on the material used, the quality of the installation, and the local environmental conditions. When properly installed, high-quality flashing is exceptionally durable.

- Aluminum or Copper: These are considered premium, lifetime materials. A well-made copper or heavy-gauge coated aluminum flashing can easily last 30-50 years or more, often outlasting the shingles around them. They offer superior resistance to corrosion and are the best choice for long-term peace of mind.

- Galvanized Steel: This is a more common, budget-friendly option. However, its lifespan is significantly shorter, typically ranging from 10 to 15 years. The zinc coating that protects the steel from rust eventually wears away, especially in humid climates like Alabama’s or coastal areas with salt spray, where it is highly susceptible to rapid corrosion.

Regular annual inspections from the ground with binoculars are key to monitoring the condition of any flashing material and catching signs of degradation, like rust streaks or pitting, early on.

Are pre-made or site-fabricated kickout flashings better?

In our professional experience, we almost exclusively recommend and install prefabricated, seamless kickout flashings. These products are engineered and manufactured in a controlled factory setting to offer consistent quality and performance. They are molded from a single piece of material, eliminating the seams that are a common failure point in site-built versions. Most importantly, they are manufactured with the precise 110-degree angle required for optimal water diversion. This reliability and precision make them a vastly superior choice for ensuring a permanent, watertight seal.

While a highly skilled metal craftsman can create an effective site-fabricated flashing from sheet metal, this method is far more prone to human error. Incorrect angles, poorly sealed seams, or inadequate size can severely compromise their function from day one. For maximum protection and to eliminate variables, the consistency and engineered design of a prefabricated flashing are unparalleled.

Can sealant, caulk, or tape be an effective long-term fix for a leaking kickout flashing?

No. Sealants, roofing cement, and specialized flashing tapes should only ever be considered a temporary, emergency patch for a very minor gap or pinhole to prevent further damage until a proper repair can be made. They are absolutely not a permanent solution.

Your roof is in a constant state of movement, expanding and contracting with daily and seasonal temperature changes. This thermal movement causes sealants and tapes to quickly degrade. They lose their elasticity, become brittle, crack, and peel away from the surface, often within a single season. The leak will inevitably return, and in the meantime, the sealant can trap moisture, potentially accelerating corrosion of the metal underneath. For any lasting repair, especially if the flashing is corroded, physically damaged, or was installed incorrectly in the first place, a full replacement is the only reliable and professional solution.

Does my homeowners insurance cover a failed kickout flashing?

This is a common and important question. Generally, homeowners insurance policies are designed to cover damage from sudden and accidental events (e.g., a tree falling on the roof, a hailstorm). They typically do not cover damage resulting from gradual failure, lack of maintenance, or improper installation. Therefore, the cost to replace the failed flashing itself is usually not covered. However, the ensuing damage—such as the rotted wall sheathing, damaged drywall, and mold remediation inside your home—may be covered, depending on the specific language of your policy. It is crucial to review your policy and consult with your insurance agent to understand your coverage.

I’m getting a new roof. What should I specify to my roofer about kickout flashing?

This is the perfect time to ensure your home is protected. Be proactive. When reviewing a contract for a new roof, you should explicitly request and ensure it is written into the scope of work that prefabricated, seamless kickout diverters will be installed at all roof-to-wall terminations where required. Ask the contractor to confirm that the new flashing will be properly integrated with the new step flashing and the home’s weather-resistive barrier according to current IRC standards and manufacturer specifications. Getting this detail in writing before the job starts holds the contractor accountable and ensures this critical component is not overlooked.

Conclusion: Protect Your Investment with Proactive Maintenance

Kickout flashing is a small, inexpensive, yet critically important component that serves as an unsung hero in the battle against water damage. When correctly installed and maintained at every roof-to-wall intersection, it diligently safeguards your home’s structural skeleton, prevents the costly and hazardous growth of rot and mold, and ultimately saves you from the financial and emotional toll of extensive repairs. At Prime Roofing & Restoration, we have a deep understanding of the unique challenges that Alabama’s weather—from the intense humidity and heavy rains in Alabaster to the salt-laden air in Gulf Shores—poses to a home’s exterior. We are committed to providing robust, long-term solutions that are built to stand the test of time.

Ignoring a missing, damaged, or improperly installed kickout flashing is a gamble you cannot afford to take. It is a direct invitation for water intrusion, a relentless force that can silently compromise your home’s framing, sheathing, siding, and even its foundation. Timely inspection and proactive repair kickout flashing roof maintenance is not an expense; it is an investment that can save you thousands of dollars and preserve the value of your property. We encourage all homeowners to conduct regular visual inspections, especially after major storms, as this is your best defense against catastrophic water damage.

While this guide provides a comprehensive overview, many flashing issues, especially those involving underlying rot, are complex and dangerous to tackle on your own. For comprehensive roof inspections, professional diagnostics, and expert repairs, trust the licensed and insured professionals at Prime Roofing & Restoration. Don’t let a small leak turn into a major structural problem. Protect your home and your peace of mind.

Contact Prime Roofing & Restoration Today for a Free Estimate:

- Company: Prime Roofing & Restoration

- Address: 123 Main Street, Alabaster, AL 35007 (Example Address)

- Phone: (205) 555-7663

- Request Service: Reach out to our friendly roofers in Alabaster, AL for expert service and the peace of mind you deserve.

- View on Map: Google Maps Link