Why Industrial Roof Repairs Are Critical for Your Business Operations

Industrial roof repairs are specialized services designed to address the unique challenges of manufacturing facilities, warehouses, and other industrial buildings. When your business needs reliable and professional roofing solutions, Prime Roofing & Restoration provides expertise across Alabama. Unlike residential or commercial office buildings, industrial roofs must withstand heavy equipment, chemical exposure, and extreme weather while covering vast areas, often requiring materials like TPO, EPDM, or metal roofing systems.

Key Industrial Roof Repair Solutions:

- Leak Detection & Repair: Using advanced methods to locate and seal water infiltration points.

- Membrane Restoration: Applying specialized coatings that can extend roof life by up to 10 years.

- Drainage Improvements: Addressing ponding water to prevent structural damage.

- Flashing Replacement: Sealing critical areas around HVAC units and other penetrations.

- Emergency Response: Offering 24/7 services for urgent repairs that threaten operations.

A single leak can damage expensive equipment, disrupt production, and create safety hazards. Research shows that addressing issues promptly with professional commercial roof repairs can prevent up to 98% of major structural problems that would otherwise require costly replacements.

Companies with aging or leaking roofs often face increased energy costs, inventory damage, and potential business interruption, making proactive maintenance essential. I’m Bill Spencer, owner of Prime Roofing & Restoration, and my hands-on experience with complex industrial roofing systems has taught me that early intervention is key to maximizing your roof’s performance and lifespan.

Why Industrial Roofs Are a Different Beast: Materials & Lifespans

Industrial roofs are engineered systems designed to handle challenges that would destroy typical roofing materials. They must support massive HVAC units, resist chemical vapors, and meet strict safety codes across surface areas that can span several acres. These complex systems require specialized engineering, not simple repairs.

The materials that can handle these demands are as tough as they come. TPO (Thermoplastic Polyolefin) reflects heat while resisting tears and chemicals. EPDM (Ethylene Propylene Diene Monomer), or rubber roofing, stays flexible in extreme temperatures. For facilities with grease or chemical exposure, PVC (Polyvinyl Chloride) offers superior resistance. Other robust options include long-lasting Metal roofing systems, multi-layer Modified Bitumen, traditional Built-Up Roofing (BUR), and seamless Spray Foam (SPF).

Understanding these materials is crucial for effective industrial roof repairs, as using the wrong approach can void warranties or create bigger problems.

Typical Lifespans and Environmental Impact

While most industrial roofing materials are designed to last 15-20 years, Alabama’s climate can significantly impact that timeline. Proper maintenance and timely repairs, however, can often extend these lifespans well beyond their expected range.

- UV Exposure: The intense Alabama sun breaks down roofing membranes over time, causing brittleness and cracking.

- Weather Impact: Severe storms, heavy rains, and hail can damage even the toughest materials.

- Temperature Swings: Constant expansion and contraction from summer heat to winter freezes create stress on seams and flashing.

- Poor Drainage: Ponding water accelerates material breakdown and creates perfect conditions for leaks.

What makes industrial roof repairs different is understanding how these environmental factors interact with your specific facility’s demands. A chemical plant faces different challenges than a warehouse, and our repair strategies reflect those differences. To learn more about how environmental factors affect roof longevity, you can learn about roof longevity from the NRCA. Your industrial roof is a critical component of your facility’s infrastructure that requires specialized knowledge to maintain properly.

Red Flags: Identifying Common Industrial Roof Problems Before They Escalate

The key to avoiding costly downtime and extensive damage is early detection. Most roof failures give you warning signs, and if you know what to look for, you can catch them early and save thousands of dollars in industrial roof repairs.

Think of it as your roof’s way of asking for help before it’s too late. A small water stain today could become a flooded warehouse tomorrow. A minor crack might seem harmless, but it’s an open invitation for water and wind to cause serious damage.

The Telltale Signs Your Roof Needs Repair

- Water Stains: Brown or yellow marks on ceilings and walls are clear evidence that water has found a way inside. Even a small stain can indicate a larger problem.

- Ponding Water: Puddles that remain for more than 48 hours after rain add tremendous weight to your roof and accelerate material degradation.

- Blistering or Cracking: Blisters indicate trapped moisture, while cracks show that materials are aging and becoming brittle from weather exposure.

- Rust or Corrosion: Rust on metal components like flashing and vents eats away at the metal, creating weak spots that can become leaks.

- Loose Seams: Separating or lifting seams on membrane roofs provide a direct path for water to enter your building.

- Increased Energy Bills: A sudden spike in heating or cooling costs can mean your roof is losing its insulating capabilities due to moisture or material breakdown.

If any of these signs sound familiar, don’t wait for the problem to worsen. Early action can prevent a small repair from becoming a major replacement.

Top Causes of Leaks and Failures

Understanding why roofs fail helps you prevent problems before they start.

- Poor Drainage: Clogged gutters and drains cause water to pool, stressing the structure and degrading materials.

- Unsealed Openings: Failed seals around HVAC units, vents, and pipes are common entry points for water.

- Membrane Damage: Punctures from hail, wind-blown debris, or even foot traffic can compromise your roof’s integrity.

- Aging Materials: Over time, UV exposure and weather cause all roofing materials to become more vulnerable to damage.

- Extreme Weather: Alabama’s intense heat, storms, and hail put constant stress on industrial roofs, gradually weakening them.

- Inadequate Ventilation: Trapped heat and moisture from poor airflow can damage roofing materials from below.

The Ultimate Guide to Industrial Roof Repairs and Restoration

When you’ve identified a problem, a swift and effective response is crucial. The right approach depends on the roof’s age, the extent of the damage, and your long-term budget. Understanding your options ensures you make the best choice for your facility.

Once you’ve spotted warning signs, time is of the essence. A minor leak can quickly turn into a major structural issue if action is delayed. At Prime Roofing & Restoration, we guide facility managers through this critical decision, balancing immediate needs with long-term financial planning.

Repair vs. Replacement: Making the Right Financial Decision

This is the question that keeps facility managers up at night. Consider these key factors to make a clear decision:

- Cost-Effectiveness: If repair costs exceed 25-30% of a full replacement within a two-year period, replacement is often the smarter financial choice.

- Extent of Damage: A single, localized leak is a good candidate for repair. Multiple leaks across different sections suggest systemic failure that may require replacement.

- Roof Age: If your roof is approaching the 15-20 year mark and showing widespread wear, replacement is a proactive investment. A newer roof with isolated damage is almost always worth repairing.

- Long-Term Goals: A new roof can boost property value if you plan to sell. If you’re staying, a quality replacement provides decades of protection.

- Warranty Status: Check if repairs are covered under an existing warranty. A new roof comes with fresh manufacturer and workmanship guarantees.

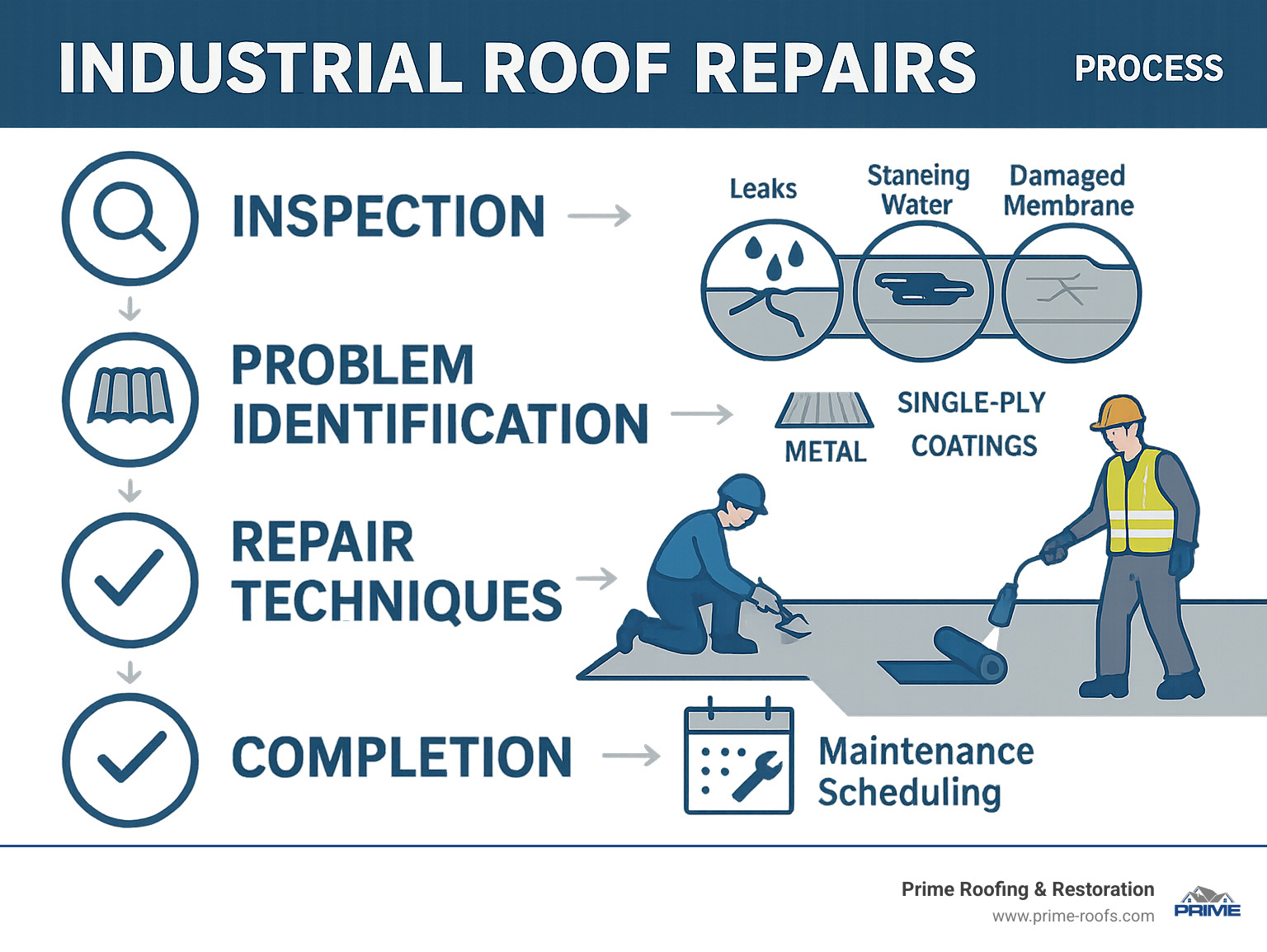

Best Practices for High-Quality Industrial Roof Repairs

Our approach to industrial roof repairs focuses on precision, quality materials, and lasting solutions.

- Thorough Inspection: We use advanced technology like infrared thermography to find problems invisible to the naked eye.

- Proper Material Matching: We ensure repair materials are fully compatible with your existing roofing system to prevent chemical reactions and further damage.

- Seam and Flashing Repair: We use industry-specific techniques to reinforce these common weak points, often upgrading to corrosion-resistant materials.

- Advanced Leak Detection: We use cutting-edge methods to pinpoint the exact source of leaks, ensuring we fix the real problem the first time.

- Safety First: We strictly follow industry safety standards, conducting thorough risk assessments to protect our team and your operations.

The Power of Protective Coatings

Protective coatings are engineered solutions that can transform an aging roof into a high-performance system. These coatings can extend your roof’s lifespan by years, sometimes with up to a 10-year guarantee. They form a seamless, monolithic layer that waterproofs the entire surface, sealing small cracks and preventing new leaks. Additionally, UV-reflective “cool roof” coatings can dramatically lower energy costs by reducing heat absorption, with some clients seeing savings of 20% or more.

The Business Case: How Proactive Maintenance Protects Your Bottom Line

Investing in your industrial roof isn’t an expense—it’s a strategic business decision. A well-maintained roof protects your assets, ensures operational continuity, and can even lower your energy costs. A proactive maintenance plan is the most effective way to maximize your roof’s lifespan and prevent the massive financial disruption of a sudden failure.

The reality is that industrial roof repairs become exponentially more expensive when you wait for a crisis. A $500 seam repair can quickly escalate into a $50,000 emergency replacement when water infiltrates your building’s structure. Smart facility managers view roof maintenance as an investment, not an expense.

The Long-Term Financial Benefits of Timely Repairs

When you address roofing issues promptly, you’re protecting your entire operation from a cascade of costly consequences.

- Avoiding Structural Damage: A small leak can lead to rotted supports, corroded beams, and mold problems, turning a minor repair into a major structural overhaul.

- Lowering Energy Costs: A compromised roof can increase energy bills by 15-25% as your HVAC system works overtime. Proper maintenance keeps your building envelope tight and efficient.

- Preventing Inventory Loss: For warehouses and manufacturers, a single leak can destroy valuable materials or products, leading to production delays and lost revenue.

- Maintaining Property Value: A well-maintained roof with a documented history significantly boosts your property’s marketability and value.

- Fewer Emergencies: Planned maintenance is far less disruptive and costly than emergency repairs, which often cost 3-5 times more and occur at the worst possible times.

Choosing a Qualified Industrial Roofing Contractor

Selecting the right partner for your industrial roof repairs is critical. Here’s what to look for in a professional contractor:

- Licensing and Insurance: Ensure the contractor holds proper commercial licensing and comprehensive insurance to protect you from liability.

- Proven Industrial Experience: Look for contractors with years of demonstrated experience specifically with industrial facilities and complex membrane systems.

- Strong Local Reputation: Check Google reviews and ask for local references. A contractor with deep community ties has a reputation to uphold.

- Excellent Safety Record: The contractor must have comprehensive safety protocols and a track record of adhering to OSHA standards.

- Detailed, Transparent Quotes: A reputable company provides a clear breakdown of all costs, including materials, labor, and warranty information.

Your Local Partner for Industrial Roof Repairs in Alabaster, AL

When your industrial facility needs reliable roofing services, having a trusted local partner makes all the difference. At Prime Roofing & Restoration, we’ve built our reputation on understanding what businesses in Alabaster and Central Alabama need from their roofing contractor.

We know Alabama’s climate is tough on industrial roofs. From scorching summer heat to severe thunderstorms, your roof takes a beating year-round. We have spent years perfecting our approach to industrial roof repairs, working with everything from sprawling warehouse TPO membranes to complex manufacturing facility metal roofs.

What sets us apart is our commitment to being your long-term roofing partner, providing ongoing maintenance to prevent small issues from becoming major headaches. Our team of licensed experts understands that industrial roof problems can’t wait. When your roof fails, your operation is at risk, which is why we offer 24/7 emergency services to respond quickly.

Whether you have a minor leak or need a comprehensive assessment of an aging roof system, we provide custom solutions. From meticulous inspections to complete replacements with energy-efficient materials, we’ve got you covered.

Prime Roofing & Restoration

Address: 5 Brown Cir, Alabaster, AL 35007

Phone: (205) 661-8190

We proudly serve businesses throughout Shelby County and the surrounding areas. When you’re searching for experienced roofers near me in Alabaster, AL, you can count on us to protect your business investment with quality materials and proven craftsmanship.

Protect Your Investment with Expert Roof Care

Your industrial roof is the silent guardian of your entire operation. It shields millions of dollars in equipment, protects valuable inventory, and keeps your employees safe. Investing in proper roof care isn’t just smart business—it’s essential.

We’ve explored the unique world of industrial roof repairs, from specialized materials like TPO and EPDM to the warning signs that demand attention. We’ve also covered the strategic thinking behind choosing between targeted repairs and a full replacement.

The bottom line is crystal clear: proactive maintenance and timely industrial roof repairs are your best defense against catastrophic failures that can shut down operations and drain your budget. A small leak today can become a flood of problems tomorrow. A repair that might have cost a few hundred dollars can quickly escalate into tens of thousands in damages and lost production.

The good news is that you’re in control. By partnering with experienced professionals who understand the complexities of industrial roofing, you can extend your roof’s lifespan, lower energy costs, and gain peace of mind knowing your operation is protected.

Don’t wait for a small issue to become a major headache. Your facility, your employees, and your bottom line deserve a proactive approach to roof maintenance. Take charge of your roof’s future today.

Ready to protect your investment? Contact us for a free, no-obligation quote and let’s work together to ensure your industrial roof stands strong for decades to come.