What is an EPDM Roof System?

An EPDM roof system is a synthetic rubber roofing membrane made from ethylene propylene diene monomer, providing durable, long-lasting protection for flat and low-slope roofs. With a track record of over 50 years, EPDM is one of the most reliable choices for commercial and residential roofing solutions. Here’s a quick overview:

Key Features:

- Membrane: A single-ply rubber sheet, typically 45-90 mils thick.

- Installation: Can be fully adhered, mechanically attached, or ballasted.

- Colors: Available in black for heat absorption or white for solar reflectivity.

- Lifespan: 25-30 years, potentially up to 50 with proper maintenance.

- Cost: Ranges from $7-17 per square foot.

Primary Benefits:

- Superior weather, hail, UV, and ozone resistance.

- Remains flexible in extreme cold (down to -60°F).

- Requires low maintenance and simple repairs.

As owner of Prime Roofing & Restoration, I’ve seen how an EPDM roof system offers exceptional value for Alabama property owners. Its durability and storm resistance make it an ideal choice for our challenging Gulf Coast climate.

Understanding the EPDM Membrane: Types, Thickness, and Colors

An EPDM roof system is more than just a rubber sheet; it’s a set of components working together to protect your property. Understanding these parts helps you make an informed investment.

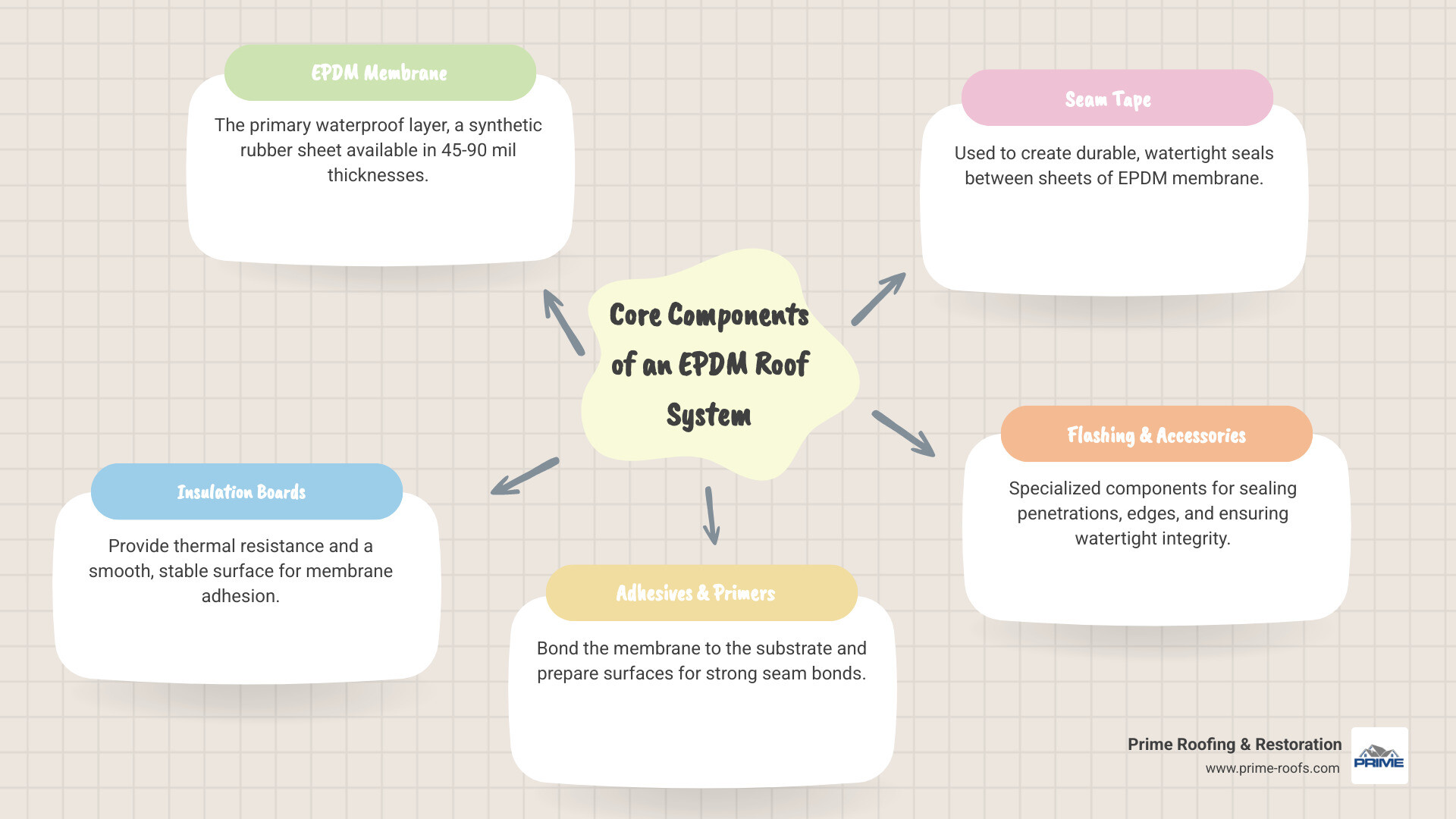

The Core Components of an EPDM Roof System

Each part of an EPDM system is vital for creating a watertight, durable roof.

- EPDM Membrane: The primary black or white rubber sheet that waterproofs the roof.

- Insulation Boards: Provide thermal protection and a smooth surface for the membrane.

- Adhesives & Primers: Bond the membrane to the insulation or roof deck in fully adhered systems.

- Seam Tape: Creates watertight seals where membrane sheets overlap, preventing leaks.

- Flashing: Seals vulnerable areas like pipes, vents, and roof edges.

- Fasteners: Screws and plates that anchor the membrane to the deck in mechanically attached systems.

For more details on how these materials come together in a full roof replacement, our team can provide a comprehensive overview.

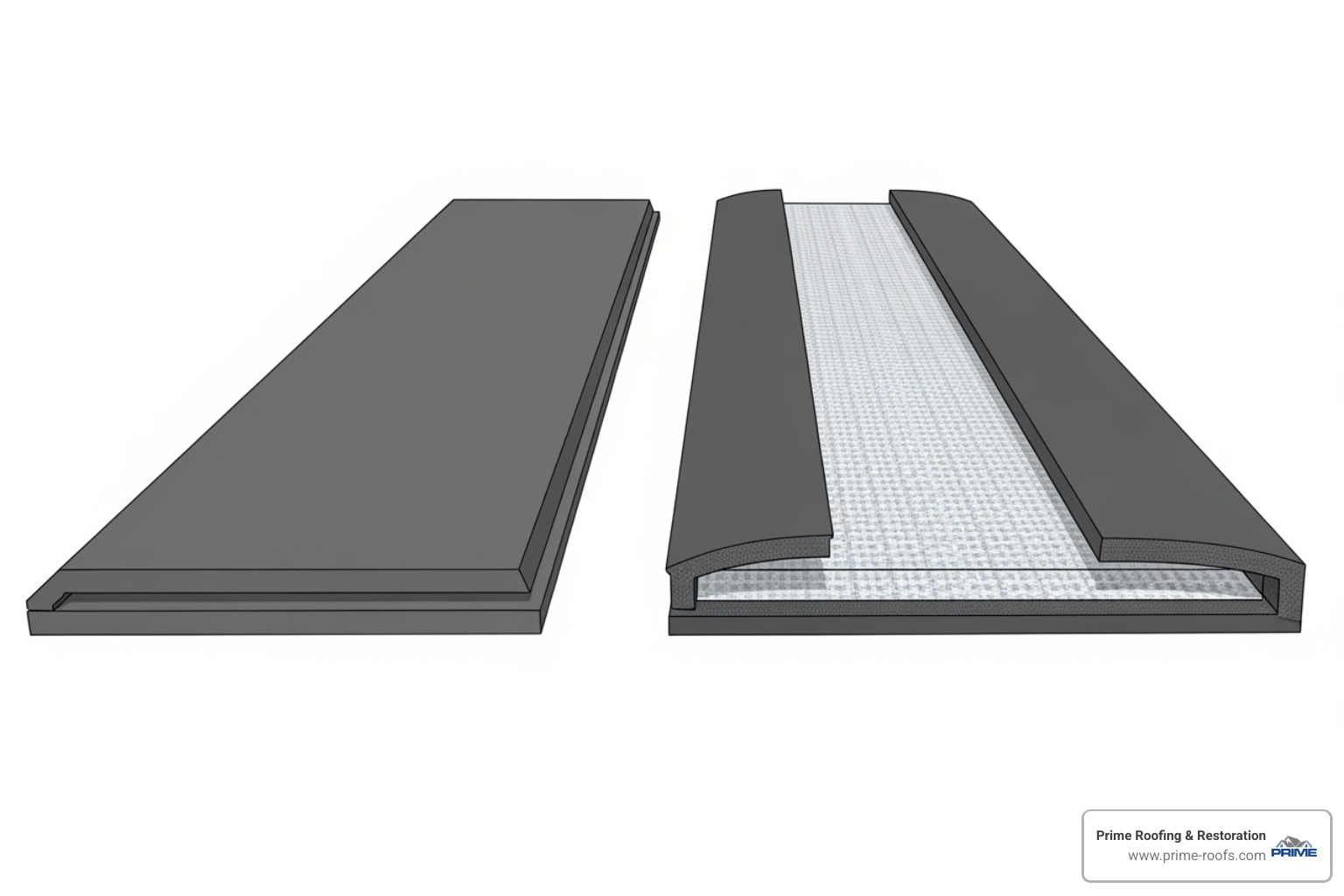

Choosing Your Membrane: Reinforced vs. Non-Reinforced

EPDM membranes come in different types to suit various needs and budgets.

- Standard (Non-Reinforced) EPDM: A highly flexible solid rubber sheet that excels at handling temperature fluctuations. It’s a classic choice but can be more prone to punctures.

- Reinforced EPDM: Includes an internal polyester fabric layer, dramatically improving puncture and tear resistance. This is ideal for roofs with heavy foot traffic or in harsh weather zones.

- Fleece-Backed EPDM: Features a polyester fleece on its underside, which adds cushioning and improves adhesion. It’s great for re-roofing over less-than-perfect surfaces.

Thickness and Color: What’s Right for Your Building?

Finalizing your EPDM roof system involves choosing the right thickness and color for your building’s needs and climate.

Membrane Thickness is key to durability:

- 45-mil (0.045″): The most economical option, suitable for low-risk applications.

- 60-mil (0.060″): The industry standard, offering a great balance of durability and cost for a 25-30 year lifespan.

- 90-mil (0.090″): The premium choice for maximum protection against punctures and extreme weather.

Color Choice impacts energy efficiency:

- Black EPDM: Absorbs heat, which can help reduce heating costs in colder climates and melt snow faster.

- White EPDM: Reflects sunlight, keeping buildings cooler and lowering air conditioning costs. In a hot climate like Alabama’s, a white roof can be up to 80°F cooler than a black one, making it a smart choice for energy savings.

Understanding these options is crucial for designing the right system. For more on EPDM’s environmental benefits, the EPDM Roofing Association is an excellent resource.

The Top 5 Advantages of EPDM Roofing

An EPDM roof system is a leading choice for commercial and low-slope properties due to its impressive advantages in protection, efficiency, and long-term value. Here are five key reasons why EPDM stands out.

1. Exceptional Durability and a 30+ Year Lifespan

Known as a “bulletproof rubber roof system,” EPDM has a proven history of performance spanning over 50 years. Its longevity comes from:

- Weather & Hail Resistance: The rubber composition absorbs impacts and resists damage from sun, rain, and hail—a critical benefit in storm-prone areas.

- UV and Ozone Resistance: EPDM’s chemical makeup, especially the carbon black in black membranes, naturally resists degradation from UV rays and ozone.

- Superior Flexibility: The membrane remains pliable in extreme cold (past -60°F) and can stretch over 300% without tearing, accommodating building movement.

With proper installation, an EPDM roof can last 25-30 years, with some lasting 50 years or more.

2. Cost-Effectiveness and Low Life-Cycle Costs

EPDM shines with its long-term affordability. While installation costs are competitive (typically $7-$17 per sq. ft.), the real savings come from:

- Low Maintenance Needs: EPDM requires minimal upkeep.

- Simple Repairs: Punctures or tears are easy and inexpensive to patch.

This combination of durability and low maintenance results in an exceptionally low life-cycle cost, offering a great return on investment. Understanding the scope of a project is key to budgeting, and our team can provide a clear estimate for your roof replacement.

3. Energy Efficiency and Rooftop Safety

An EPDM roof system contributes to energy savings and a safer building.

- Black Membranes (Cold Climates): Absorb solar heat, reducing heating costs and helping melt snow and ice.

- White Membranes (Warm Climates): Reflect sunlight to keep buildings cooler, significantly lowering air conditioning costs in places like Alabama.

- Safety Features: EPDM is fire-resistant and offers a slip-resistant surface when dry, improving safety for rooftop access.

4. Versatility and Adaptability

EPDM’s flexibility makes it suitable for a wide range of flat and low-slope roofs on commercial and residential buildings. It’s manufactured in large rolls (up to 50 feet wide), which reduces the number of seams and minimizes potential leak points. This adaptability makes it a reliable choice for diverse climates and building designs.

5. Environmental Considerations

EPDM is an environmentally conscious choice for several reasons:

- Long Service Life: A longer lifespan means less frequent replacement and reduced landfill waste.

- Recyclability: The material is recyclable and can be repurposed.

- Energy Savings: White EPDM reduces cooling demands, lowering a building’s carbon footprint.

- Inert Material: EPDM doesn’t release harmful pollutants into the environment and won’t contaminate rainwater runoff.

EPDM Installation Methods and Maintenance Needs

The performance of an EPDM roof system depends heavily on proper installation and consistent maintenance. Here’s what you need to know about both.

How is an EPDM Roof Installed?

EPDM’s adaptability allows for three primary installation methods, each suited for different needs and budgets.

- Fully Adhered System: The membrane is glued directly to the substrate. This method offers the best wind uplift resistance and a smooth, aesthetic finish, making it a premium choice for high-wind areas.

- Mechanically Attached System: The membrane is secured with fasteners (screws and plates) at the seams. This is often the most cost-effective and quickest method, making it a popular choice for commercial roofing.

- Ballasted System: The membrane is laid loose and held down with a layer of ballast, like river rock or pavers. This is an economical and fast option, but the building must be able to support the significant extra weight.

Regardless of the method, ensuring seam integrity with specialized tapes and adhesives is critical for a watertight seal. Key accessories like flashing, pipe boots, and sealants are also essential for protecting vulnerable areas.

Keeping Your EPDM Roof in Peak Condition

While EPDM is a low-maintenance material, proactive care is key to maximizing its 50+ year potential lifespan. We recommend the following:

- Routine Inspections: Have a professional inspect your roof twice a year (spring and fall) to check for wear, punctures, or seam issues.

- Keep it Clean: Regularly remove leaves, branches, and other debris that can trap moisture and hide damage.

- Check Seams and Drains: Pay close attention to seams for any signs of separation and ensure gutters and drains are clear to prevent ponding water.

- Address Ponding Water: Water that sits for more than 48 hours can accelerate wear and should be addressed by a professional.

- Protect the Surface: Use walkway pads in high-traffic areas and avoid dragging sharp objects across the membrane.

Following these tips can significantly extend the life of your roof. For any major concerns or repairs, it’s always best to consult with professionals who specialize in services like roof replacement to ensure the work is done correctly.

Finding Your EPDM Roofing Expert in Alabaster, AL

The quality of your EPDM roof system is only as good as the contractor who installs it. A poor installation can turn a great product into a costly headache. When searching for an expert in Alabama, look for a contractor who is licensed, insured, and has local experience with our state’s unique weather.

Manufacturer certifications from brands like Carlisle or Firestone are another key indicator of quality, as they show a commitment to proper techniques and best practices. Be sure to review project galleries and customer testimonials to gauge a contractor’s work quality and professionalism.

At Prime Roofing & Restoration, we’ve built our reputation on delivering exceptional EPDM roof systems throughout Central Alabama. Our team combines technical expertise with clear communication and solid warranties. For more tips, see our guide on choosing a roofer you can trust.

Contact Your Local Roofing Professionals

Ready to see if an EPDM roof system is right for your property? Our team is here to provide a thorough inspection and a detailed estimate.

Prime Roofing & Restoration

Address: 5 Brown Cir, Alabaster, AL 35007

Phone: (205) 661-8190

We proudly serve the Alabaster, AL area and surrounding communities. We’re committed to delivering roofing solutions that protect your property for decades.

Frequently Asked Questions about EPDM Roofing

We get a lot of questions about EPDM roof systems. Here are clear, straightforward answers to some of the most common inquiries we receive from property owners.

How much does an EPDM roof system cost?

The cost of an EPDM roof system is generally cost-effective, with long-term value that outweighs the initial investment. Average costs range from $7.00-$17.00 per square foot, including materials and installation.

Several factors affect the final price:

- Membrane Thickness: Thicker 60-mil or 90-mil membranes cost more but offer superior durability.

- Installation Method: Fully adhered systems are typically more labor-intensive than mechanically attached or ballasted systems.

- Roof Complexity: Roofs with many vents, skylights, or irregular shapes require more labor and increase costs.

- Project Size: Larger roofs often have a lower per-square-foot cost due to economies of scale.

While initial cost is a factor, EPDM’s long lifespan and low maintenance needs result in a lower overall life-cycle cost compared to many other roofing materials.

Can you walk on an EPDM roof?

Yes, you can walk on an EPDM roof system for occasional maintenance and inspections. However, to avoid damage, follow these guidelines:

- Use Walkway Pads: For areas with frequent foot traffic, install designated walkway pads to protect the membrane from wear and tear.

- Be Cautious When Wet: EPDM can be slippery when wet, so exercise extra care.

- Avoid Sharp Objects: Be mindful of tools, screws, or sharp debris that could puncture the membrane.

While light access is fine, for any significant concerns, a professional assessment for a potential roof replacement is the safest approach to avoid causing unintended damage.

Is EPDM environmentally friendly?

Yes, an EPDM roof system has several positive environmental attributes, making it a sustainable choice.

- Long Service Life: EPDM roofs can last 30-50 years, which means fewer replacements and less waste sent to landfills.

- Recyclability: The material is recyclable and can be repurposed at the end of its life.

- Energy Efficiency: White EPDM membranes reflect sunlight, reducing a building’s cooling needs and lowering its carbon footprint. This is a major benefit for reducing energy consumption.

- Inert Material: EPDM doesn’t release harmful pollutants during its manufacturing or service life.

For more details on EPDM’s sustainability, the EPDM Roofing Association offers valuable resources.

Conclusion: Is an EPDM Roof Right for You?

If you’re looking for a roofing solution that combines proven performance with exceptional long-term value, an EPDM roof system deserves serious consideration. Your roof is one of your property’s most critical assets, and choosing the right material is key to long-term protection and peace of mind.

EPDM’s benefits are clear:

- Durability: With a 50-year track record, EPDM is proven to withstand extreme temperatures, hail, and UV exposure, often lasting 30 years or more.

- Cost-Effectiveness: Low maintenance needs and simple repairs lead to a low life-cycle cost, providing excellent value over decades.

- Versatility: With multiple installation methods and color options, EPDM can be custom to fit any low-slope roof and climate, including Alabama’s hot summers.

An EPDM roof system is ideal for commercial buildings, warehouses, and residential properties with flat or low-slope roofs. It represents a reliable investment that protects your property while delivering lasting value.

For a complete roof replacement you can depend on for decades, contact our team at Prime Roofing & Restoration today. We’ll help you determine if EPDM is the right fit and provide an expert installation that maximizes your investment.