Understanding the Investment in Your Roof Replacement

Rubber roof replacement cost varies significantly based on several factors, but understanding the typical investment helps you plan your budget effectively. Here’s what you need to know:

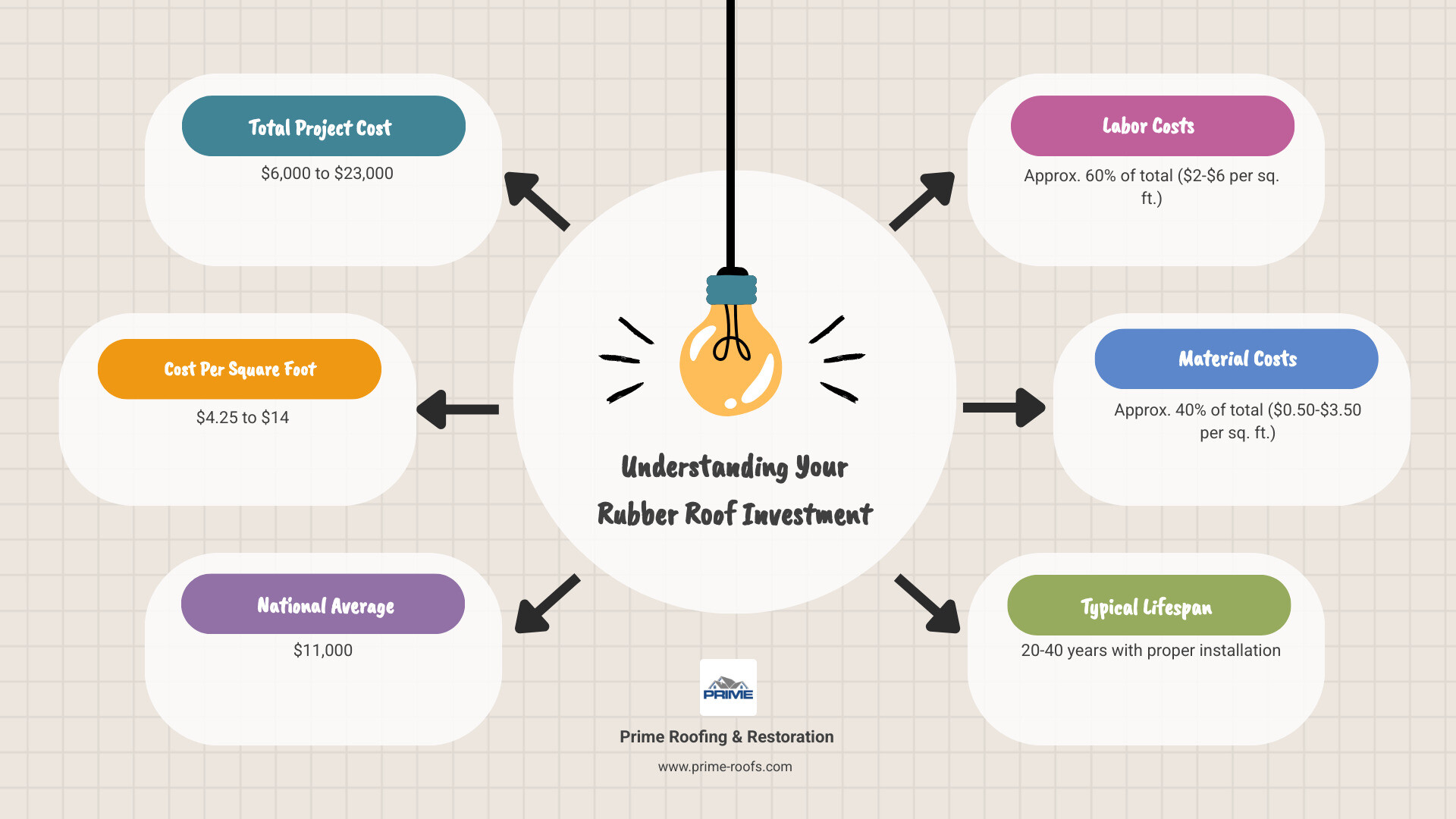

Average Cost Ranges:

- Total Project Cost: $6,000 to $23,000

- Cost Per Square Foot: $4.25 to $14

- National Average: $11,000

- Labor Costs: $2 to $6 per square foot (60% of total)

- Material Costs: $0.50 to $3.50 per square foot (40% of total)

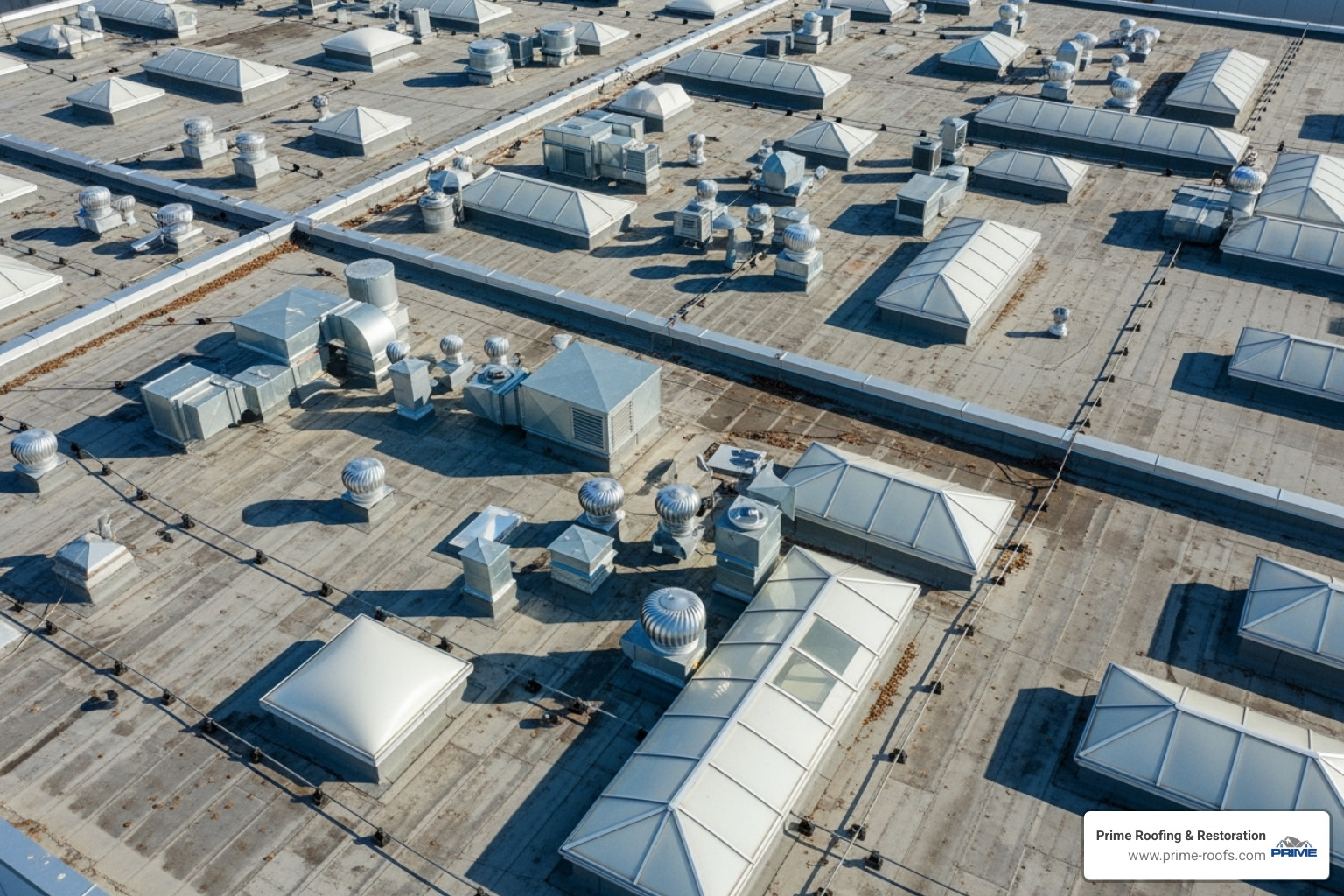

Rubber roofing is an excellent solution for flat or low-slope roofs, offering exceptional durability and long-term protection for your property. The material is made from recycled content, provides excellent weather resistance, and can last 20-40 years with proper installation.

For Alabama homeowners dealing with storm damage or aging roofs, understanding these costs helps you make informed decisions about your roofing services. The investment protects your home while potentially reducing energy bills through improved insulation and reflective properties.

As Bill Spencer, owner of Prime Roofing & Restoration with over five years of experience in Alabama’s roofing industry, I’ve helped countless property owners steer rubber roof replacement cost decisions across Central Alabama. My expertise in flat roof systems and insurance claim support ensures homeowners get the best value for their roofing investment.

Breaking Down the Average Rubber Roof Replacement Cost

Let’s get straight to the numbers. The national average rubber roof replacement cost sits around $11,000, but your actual investment could range anywhere from $6,000 to $23,000 depending on your specific situation. When you break it down per square foot, you’re looking at $4.25 to $14 – quite a range, right?

Here’s something important to understand: labor typically eats up about 60% of your total cost, while materials account for the remaining 40%. This might surprise some homeowners, but it really shows how crucial professional installation is for your roof’s long-term success. Trust me, this isn’t the place to cut corners.

For Alabama homeowners considering a roof replacement, these cost breakdowns help you understand where your money goes and why quality installation matters so much for protecting your home.

How Labor and Materials Impact Your Total

Professional installation labor runs between $2 to $6 per square foot, and this covers everything from prep work to final cleanup. Your installer needs to properly prepare the surface, lay the membrane perfectly, seal every seam, and secure everything according to manufacturer specs. One mistake here can lead to expensive water damage later.

The rubber membrane itself costs $0.50 to $3.50 per square foot for materials. The price difference comes down to a few key factors: membrane thickness (measured in mils), quality grade, and the specific adhesives and fasteners your installation method requires. Thicker membranes cost more upfront but often last longer, making them a smart investment.

Think of it this way – you wouldn’t want a surgeon using cheap tools, and you don’t want your roofer using subpar materials on something as important as your roof.

Additional Costs That Affect the Rubber Roof Replacement Cost

Beyond the basic installation, several other expenses can impact your total rubber roof replacement cost. I always tell homeowners to budget for these extras so there are no surprises.

Old roof removal adds $1 to $2 per square foot if your existing roof needs to come off first. This includes labor for tear-off and proper disposal – and yes, disposal costs money too.

Permit fees vary wildly depending on where you live, typically running $100 to $1,000. Most contractors handle this paperwork for you, but it’s still part of your total investment.

Insulation upgrades can significantly boost your energy efficiency. While this adds to upfront costs, the long-term savings on heating and cooling bills often make it worthwhile.

Underlayment, flashing, and detail work around chimneys, vents, and skylights require precision and specialized materials. This detailed work prevents leaks and protects your investment for decades.

Before any work begins, a thorough roof inspection is essential. While some contractors include basic assessments in their estimates, comprehensive inspections for older or complex roofs can cost up to $950. However, understanding your roof’s current condition helps determine the most effective long-term solution – potentially saving you thousands down the road.

Key Factors That Influence Your Final Price

Every roof tells its own story, and that story directly impacts your rubber roof replacement cost. Think of it like ordering a custom suit versus buying one off the rack – the more complex your needs, the higher the investment.

Your roof’s unique characteristics play a starring role in the final price. The size of your roof is the most obvious factor, but it’s far from the only one. Geographic location affects everything from labor rates to material availability, while the quality of materials you choose can make a significant difference in both upfront costs and long-term value.

The installation method you select becomes another crucial piece of the puzzle. Some approaches are more labor-intensive, while others require specialized equipment or additional materials. Understanding these variables helps you make informed decisions about where to invest your roofing budget.

Roof Size, Pitch, and Complexity

Square footage forms the foundation of your cost calculation – it’s simple math that more roof area requires more materials and labor time. However, the real story begins when we look at your roof’s unique personality.

Roof pitch matters more than you might expect, even with rubber roofing designed for flat surfaces. A completely flat roof might need special drainage considerations to prevent water from pooling, while a slight slope can actually help with water runoff and installation efficiency.

Roof complexity is where things get interesting – and potentially expensive. Every skylight, chimney, or vent creates what we call a penetration, and each one requires careful cutting, precise fitting, and detailed flashing work. It’s like solving a puzzle where every piece must fit perfectly to prevent leaks.

The number of corners and roofline changes also adds complexity. A simple rectangular roof installs much faster than one with multiple angles and intersections. Each corner requires custom cutting and careful sealing, which translates directly into additional labor time and material waste.

Material Choice and Installation Method

Your choice of rubber membrane and installation approach significantly shapes your rubber roof replacement cost. Membrane thickness, measured in mils, affects both your wallet and your roof’s longevity. Thicker membranes cost more upfront but often provide better puncture resistance and longer lifespans – it’s an investment in peace of mind.

The installation method you choose creates three distinct cost scenarios. A ballasted system offers the most budget-friendly option, where the membrane lies loose and heavy stones or pavers hold it in place. It’s quick to install but adds considerable weight to your building structure.

Mechanically fastened systems provide a middle-ground approach. The membrane gets secured with fasteners and plates, then seams are carefully sealed. This method offers excellent wind resistance at a reasonable cost, making it popular across Alabama where weather can be unpredictable.

Fully adhered systems represent the premium installation choice. Every square inch of membrane gets bonded to the roof deck, creating a smooth, monolithic surface with superior wind uplift resistance. While it’s the most expensive option, it delivers best durability and a clean, professional appearance.

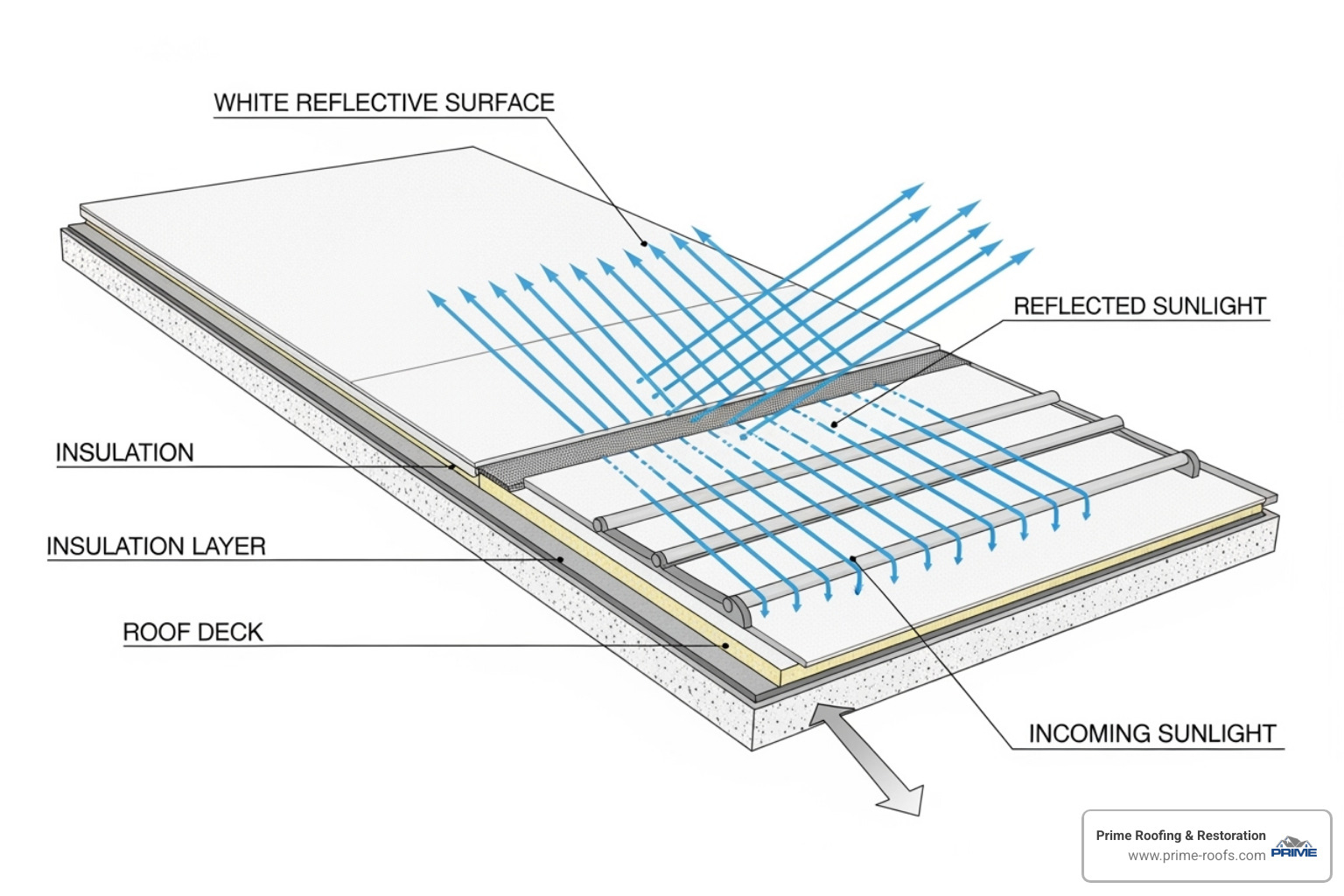

When selecting your roofing materials, color choice becomes more than aesthetic. Black membranes absorb heat, while white options reflect sunlight and reduce cooling costs – particularly valuable in Alabama’s warm climate. The energy savings from a reflective roof can help offset the slightly higher initial investment over time.

Comparing Rubber Roofing Materials

When you’re exploring rubber roof replacement cost options, you’ll find three main types of single-ply membranes that dominate the market: EPDM, TPO, and PVC. Each material brings its own personality to your roofing project, with distinct differences in cost, lifespan, and performance characteristics.

These materials fall into the category of single-ply membranes, which means they’re installed in one continuous layer rather than the multiple layers you’d find in traditional built-up roofs. Understanding the science behind these materials helps explain their behavior: Thermoset materials like EPDM cure permanently and can’t be re-melted, while Thermoplastic materials like TPO and PVC can be heat-welded and even re-melted if needed. This fundamental difference affects everything from installation methods to repair techniques.

| Material | Cost (per sq. ft.) | Lifespan | Pros | Cons |

|---|---|---|---|---|

| EPDM | $4.25 – $12 | 20-25 years | Most budget-friendly, easy to repair, excellent weather resistance, made from recycled materials. | Seams are glued (can degrade over time), often black (absorbs heat), can show dirt/mold easily. |

| TPO | $4.50 – $14 | 15-25 years | Energy efficient (white options), heat-welded seams (strong), good puncture resistance, combines qualities of rubber and plastic. | Newer material (less long-term data), quality can vary between manufacturers, more prone to expansion/contraction. |

| PVC | $5.25 – $13 | 20-30+ years | Superior leak resistance, strongest seams (heat-welded), highly durable, chemical resistant, often white for energy efficiency. | Most expensive, can be brittle in extreme cold, releases dioxins/chlorine upon breakdown (environmental concern). |

EPDM (Ethylene Propylene Diene Monomer)

Think of EPDM as the reliable workhorse of rubber roofing. At $4.25-$12 per square foot installed, it’s often the most wallet-friendly option that doesn’t compromise on quality. This material has been protecting flat roofs for over 40 years, earning its reputation through consistent performance in all weather conditions.

EPDM typically delivers a solid 20-25 year lifespan, making it an excellent value proposition. What sets it apart is its exceptional resistance to UV rays, ozone, and temperature extremes – perfect for Alabama’s varied climate conditions. The material’s composition often includes recycled rubber content, making it an environmentally conscious choice for eco-minded homeowners.

The installation process uses glued seams, which makes EPDM more accessible for DIY enthusiasts tackling smaller projects. However, professional installation ensures optimal performance and warranty protection. While traditional black EPDM can absorb heat, white-on-black options provide better energy efficiency. You can explore more details about this time-tested material at epdmroofs.org.

TPO (Thermoplastic Polyolefin)

TPO represents the middle ground in both cost and technology, typically running $4.50-$14 per square foot installed. This newer material, first introduced to roofing in the 1990s, was designed to combine the best qualities of rubber and plastic into one innovative solution.

The standout feature of TPO is its energy efficiency, particularly in white membrane options that reflect solar radiation effectively. This can translate to noticeable reductions in your cooling costs during Alabama’s hot summers. Unlike EPDM’s glued seams, TPO uses heat-welded seams that create incredibly strong, monolithic bonds highly resistant to leaks.

TPO offers a 15-25 year lifespan with good puncture resistance, making it robust enough for various applications. However, since it’s a newer material, there’s less long-term performance data compared to EPDM. Quality can also vary between manufacturers, so choosing a reputable brand and experienced installer becomes crucial.

PVC (Polyvinyl Chloride)

PVC roofing sits at the premium end of the spectrum, with costs ranging from $5.25-$13 per square foot installed. While it represents the highest upfront investment, many property owners find the superior performance justifies the additional expense.

This material boasts the longest lifespan at 20-30+ years, often exceeding expectations with proper maintenance. PVC’s heat-welded seams create exceptionally strong bonds that provide superior leak resistance compared to other options. The material also excels in harsh environments, offering excellent resistance to chemicals, grease, and punctures.

For commercial properties or homes with potential exposure to challenging conditions, PVC’s durability makes it an intelligent long-term investment. Most PVC membranes come in white or light colors, contributing to energy savings through solar reflectance. The main considerations are the higher initial cost and potential brittleness in extremely cold weather, though this is rarely an issue in Alabama’s climate.

Long-Term Value: Is a Rubber Roof a Good Investment?

When homeowners first see the rubber roof replacement cost, they often wonder if it’s truly worth the investment. The answer is a resounding yes! While the upfront expense might seem significant, rubber roofing delivers exceptional long-term value that makes it one of the smartest investments you can make for your home.

Think of it this way: with a typical lifespan ranging from 20 to 40 years, rubber roofing essentially pays for itself over time. Let’s do some simple math. If you invest $12,000 in a rubber roof that lasts 25 years, you’re paying just $480 per year to protect your entire home. That’s less than $40 per month for complete peace of mind against Alabama’s unpredictable weather.

Beyond the basic cost-per-year calculation, rubber roofs offer tremendous value through energy savings, low maintenance requirements, and exceptional durability. These benefits compound over the years, making your initial investment even more worthwhile. For comprehensive guidance on maintaining your rubber roof to maximize its lifespan, visit our roof maintenance page.

Lifespan and Durability

Rubber roofs are built like tanks – they’re designed to withstand whatever Mother Nature throws at them. With proper installation and minimal maintenance, these roofing systems consistently deliver 20 to 40 years of reliable protection. That’s potentially two decades longer than some traditional roofing materials!

What makes rubber roofing so durable? It starts with exceptional weather resistance. These membranes laugh in the face of heavy rain, high winds, and temperature swings that would stress other materials. They’re also remarkably resistant to UV radiation, which means they won’t crack, fade, or become brittle under Alabama’s intense summer sun.

Hail damage is another area where rubber roofing shines. The flexible nature of these membranes allows them to absorb impact without puncturing or cracking. Unlike rigid materials that might shatter under hail, rubber bounces back – literally. This resilience can save you thousands in repair costs over the roof’s lifetime.

Perhaps most impressive is rubber roofing’s resistance to rot and cracking. Traditional materials often deteriorate from moisture infiltration or thermal expansion, but rubber membranes maintain their integrity year after year. Most manufacturers back this confidence with substantial warranties ranging from 5 to 30 years, giving you additional peace of mind. If you’re starting to notice issues with your current roof, check out our guide on the 5 signs you need roof replacement.

Energy Efficiency and Maintenance

One of rubber roofing’s best-kept secrets is its ability to slash your energy bills. White or light-colored rubber membranes exhibit cool roof properties by reflecting sunlight instead of absorbing it. This simple physics principle can reduce your home’s heat absorption by up to 30%, leading to reduced cooling bills that add up to significant savings over time.

During Alabama’s sweltering summers, this reflective quality keeps your home more comfortable while your air conditioner works less. The energy savings often offset a substantial portion of your initial investment, making the true cost of ownership much lower than the upfront price tag suggests.

Low maintenance needs are another financial benefit that homeowners love. Unlike materials that require frequent inspections, treatments, or repairs, rubber roofs are refreshingly hands-off. Simple repairs for minor issues like small punctures are typically straightforward and inexpensive – often just requiring a patch and some adhesive.

Regular cleaning requirements are minimal too. A gentle wash every few years keeps the roof looking good and functioning properly. This simple maintenance routine helps preserve your warranty and ensures maximum lifespan. For proper moisture management throughout your home’s structure, the EPA provides excellent moisture control guidance that complements your rubber roof’s protective qualities.

The bottom line? Rubber roofing isn’t just an expense – it’s an investment that pays dividends through energy savings, minimal maintenance costs, and decades of reliable protection.

How to Budget and Get the Best Price on Your Project

Smart budgeting for your rubber roof replacement cost starts with understanding that the cheapest quote isn’t always the best value. Think of it like buying a car – you want reliability, not just the lowest sticker price. Getting the best price means finding the sweet spot between quality materials, skilled installation, and fair pricing.

Getting multiple quotes is your first line of defense against overpaying. We recommend collecting at least three detailed estimates from licensed contractors. This gives you a realistic picture of market rates and helps you spot any red flags – like quotes that seem too good to be true (they usually are) or estimates that are wildly higher than others.

Timing can save you money too. Off-season installation during late fall or early winter often brings better pricing since demand drops when the weather cools down. Just make sure temperatures are still suitable for proper installation – rubber membranes need specific conditions to cure correctly.

Choosing materials wisely means balancing upfront costs with long-term value. A slightly more expensive membrane that lasts 30 years instead of 20 often pays for itself through reduced replacement frequency. If storm damage brought you here, don’t forget about insurance claims – we help homeowners steer this process to maximize coverage and minimize out-of-pocket expenses.

DIY vs. Professional: A Key Rubber Roof Replacement Cost Decision

The internet makes DIY rubber roofing look easy, but here’s the reality: DIY cost savings can quickly turn into expensive disasters. We’ve seen too many homeowners attempt installation only to face major problems within the first year.

Risks of improper installation are serious and costly. Poorly sealed seams lead to leaks that can damage insulation, drywall, flooring, and personal belongings. Heat-welded materials like TPO and PVC require specialized equipment that most homeowners don’t own. Even EPDM, which seems more forgiving, demands precise attention to detail around penetrations and edges.

Most manufacturers will void warranties for DIY installations, leaving you completely unprotected if problems arise. Water damage from installation mistakes often costs far more than hiring professionals from the start. We’ve helped homeowners whose DIY attempts resulted in thousands of dollars in interior repairs.

Professional expertise brings peace of mind that’s hard to put a price on. Licensed roofers understand local building codes, proper flashing techniques, and how different weather conditions affect installation. They carry insurance to protect you and know how to handle unexpected challenges like rotted decking or structural issues.

Safety is another crucial factor. Roofing work involves heights, heavy materials, and potentially dangerous tools. Professional crews have the training and equipment to work safely, while DIY attempts can result in serious injuries. When emergencies strike, you’ll be glad you chose professional installation – learn more about our emergency roofing services.

Finding a Trusted Local Roofer

Finding the right contractor makes all the difference between a smooth project and a stressful experience. Start by checking licenses and insurance – any reputable contractor will gladly provide proof of both liability insurance and workers’ compensation coverage. This protects you from liability if accidents happen on your property.

Ask for references and actually contact them. Previous customers can tell you about the contractor’s work quality, communication style, and how they handled any problems that arose. Pay attention to how recent these references are – a contractor who can’t provide recent references might be struggling with quality issues.

Getting written estimates is non-negotiable. Verbal quotes lead to misunderstandings and disputes. Detailed written estimates should break down materials, labor, timeline, and any additional costs. This transparency helps you compare apples to apples when evaluating different contractors.

For homeowners in Alabaster, AL seeking professional assessment and trusted service, we’re here to help with your rubber roofing needs.

Prime Roofing & Restoration

Address: 5 Brown Cir, Alabaster, AL 35007

Phone: (205) 661-8190

Conclusion: Making the Right Choice for Your Home

When you’re weighing the rubber roof replacement cost for your home, you’re not just paying for materials and labor—you’re investing in decades of protection and peace of mind. The numbers we’ve covered, from $6,000 to $23,000 for most projects, represent far more than an expense. They represent long-term value that protects your family and property.

The choice between EPDM, TPO, and PVC isn’t just about finding the cheapest option. It’s about finding the right balance of durability, energy efficiency, and cost for your specific situation. Whether you’re dealing with a small residential flat roof or a larger commercial property, each material offers unique benefits that can serve you well for 20-40 years.

Here’s what really matters: professional installation makes all the difference. You can choose the best materials available, but without proper installation, you’re setting yourself up for headaches down the road. Water damage from poor sealing or improper flashing can cost far more than any savings from cutting corners on installation.

The importance of professional installation extends beyond just preventing problems. Licensed contractors understand local building codes, proper ventilation requirements, and how Alabama’s weather patterns affect different roofing systems. They also carry insurance and warranties that protect your investment.

At Prime Roofing & Restoration, we’ve seen how a quality rubber roof installation transforms not just the protection of a home, but the homeowner’s confidence in their investment. Our commitment to building lasting relationships means we’re here for the long haul—not just for the initial installation, but for maintenance, inspections, and any future needs.

The durability and benefits of rubber roofing make it an excellent choice for Alabama homeowners. From withstanding our summer storms to reflecting heat during those sweltering July afternoons, a properly installed rubber roof earns its keep year after year.

For expert guidance on your roof replacement project, our team brings years of experience and a commitment to quality that you can count on. We believe in transparent pricing, honest assessments, and installations that stand the test of time. Call us today for a free estimate—we’re here to help you make the best decision for your home and budget.